Noctilucent door and manufacturing method thereof

A technology of light door and luminous paint, applied in the direction of door leaf, pretreated surface, layered products, etc., can solve the problems of short luminous duration and insufficient luminous intensity of luminous door, achieve long luminous duration, improve service life, guarantee The effect of luminous properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

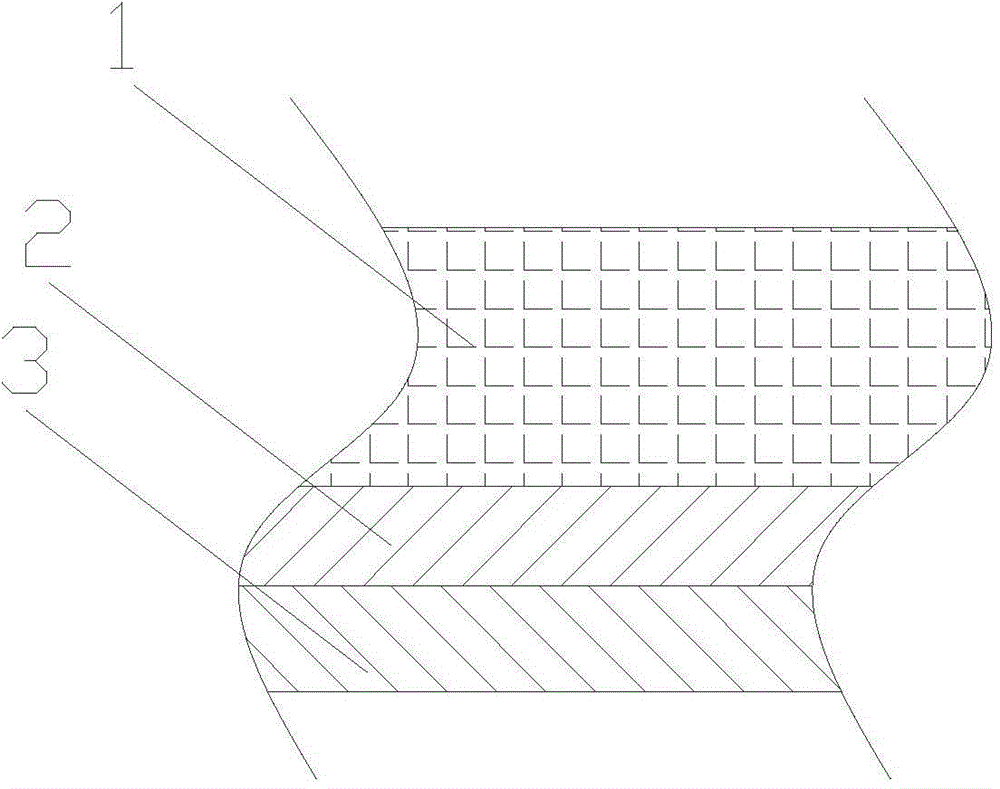

[0023] Such as figure 1 As shown, the luminous door includes a door body 1, and the outer surface of the door body 1 is sequentially provided with a luminous paint layer 2 and a varnish layer 3 from the inside to the outside. The thickness of the luminous powder layer 2 is 0.01mm-0.5mm. The thickness of the varnish is 0.05-0.5mm. By increasing the content of the luminous powder in the luminous paint, the content (mass fraction) of the luminous powder in the existing luminous paint is 2%-5%, and the content of the luminous powder in the present invention is 6%-20%.

[0024] The method for making a luminous door comprises the following steps in sequence:

[0025] S1, coating the luminous paint on the outer surface of the door body 1 to form a luminous paint layer 2;

[0026] S2, drying the luminous paint layer 2;

[0027] S3, coating the varnish on the surface of the dried luminous paint to form a varnish into 3;

[0028] S4, drying the varnish into 3 steps.

[0029] In or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com