Multi-stage traveling wave thermoacoustic engine system for cascaded utilization of waste heat of high temperature flue gas

A thermoacoustic engine, high temperature flue gas technology, applied in the direction of machines/engines, mechanisms that generate mechanical power, mechanical equipment, etc., can solve problems such as singleness, reduce system complexity, reduce heat loss, and improve heat utilization efficiency , to achieve the effect of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

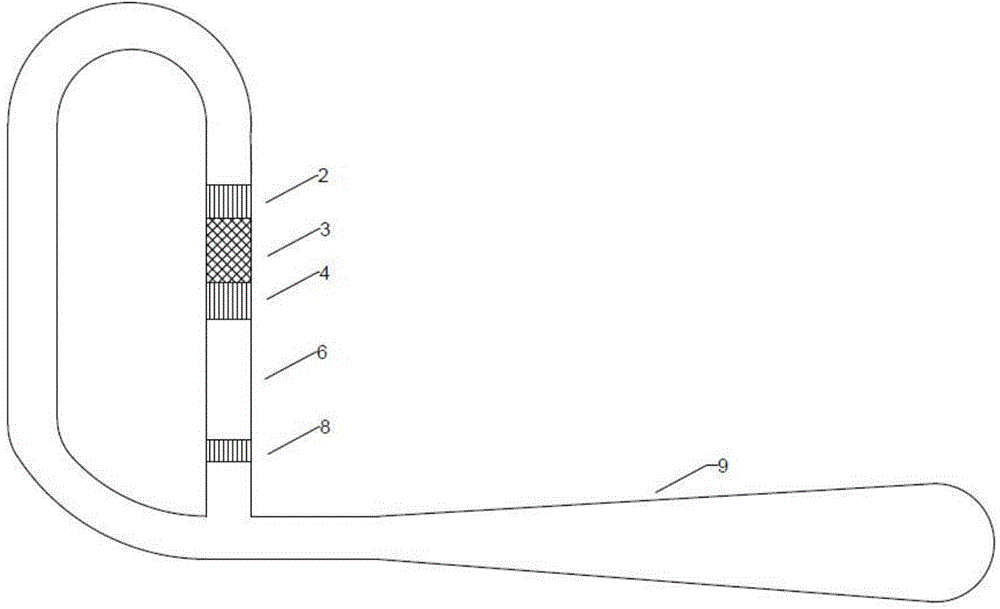

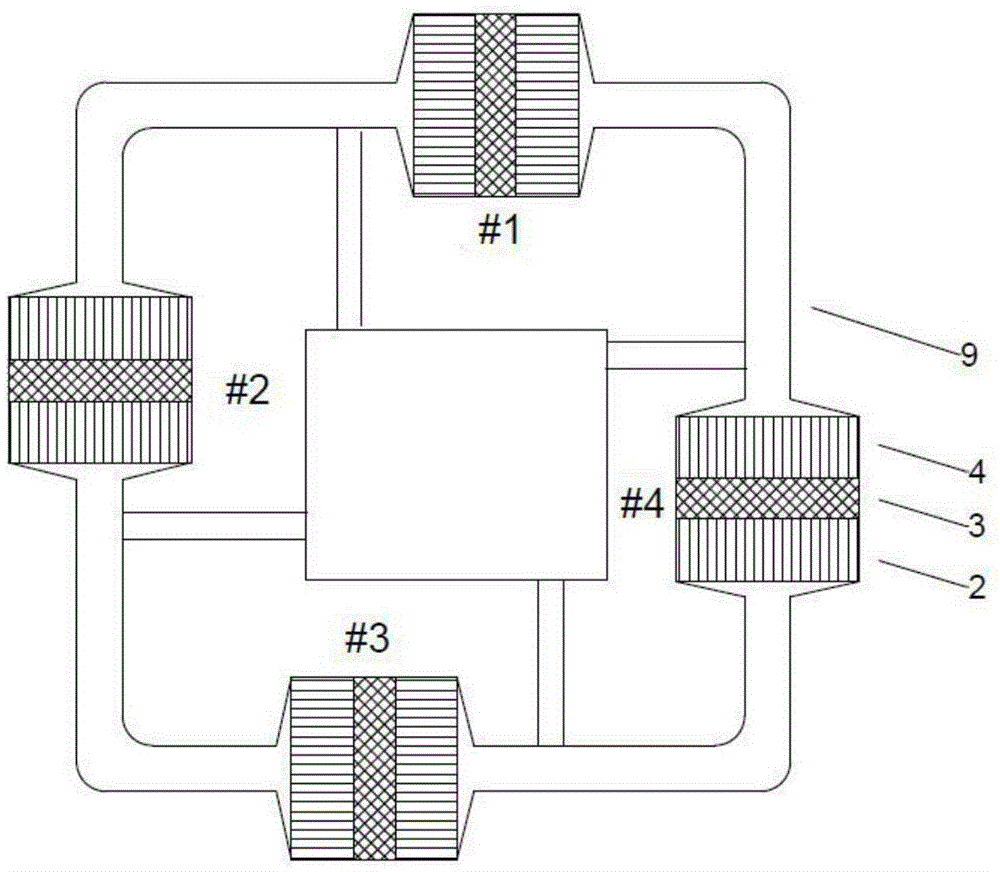

[0029] Figure 4 It is a structural schematic diagram of a multi-stage traveling wave thermoacoustic engine system (embodiment 1) for cascade utilization of high-temperature flue gas waste heat of the present invention. Such as Figure 4 As shown, the multi-stage traveling wave thermoacoustic engine system in this embodiment 1 consists of three stages (#1 thermoacoustic engine unit, #2 thermoacoustic engine unit and #3 thermoacoustic engine unit) with the same structure and different sizes of thermoacoustic The engine unit is composed of; the thermoacoustic engine units at all levels are connected end-to-end through resonance tubes 9 with different diameters to form a loop structure, and each level of thermoacoustic engine unit is in the traveling wave phase in the loop structure; each level of thermoacoustic The engine unit is composed of DC suppressor 1, main cooler 2, regenerator 3, heater 4, high temperature end laminar fluidization element 5, thermal buffer pipe 6, room ...

Embodiment 2

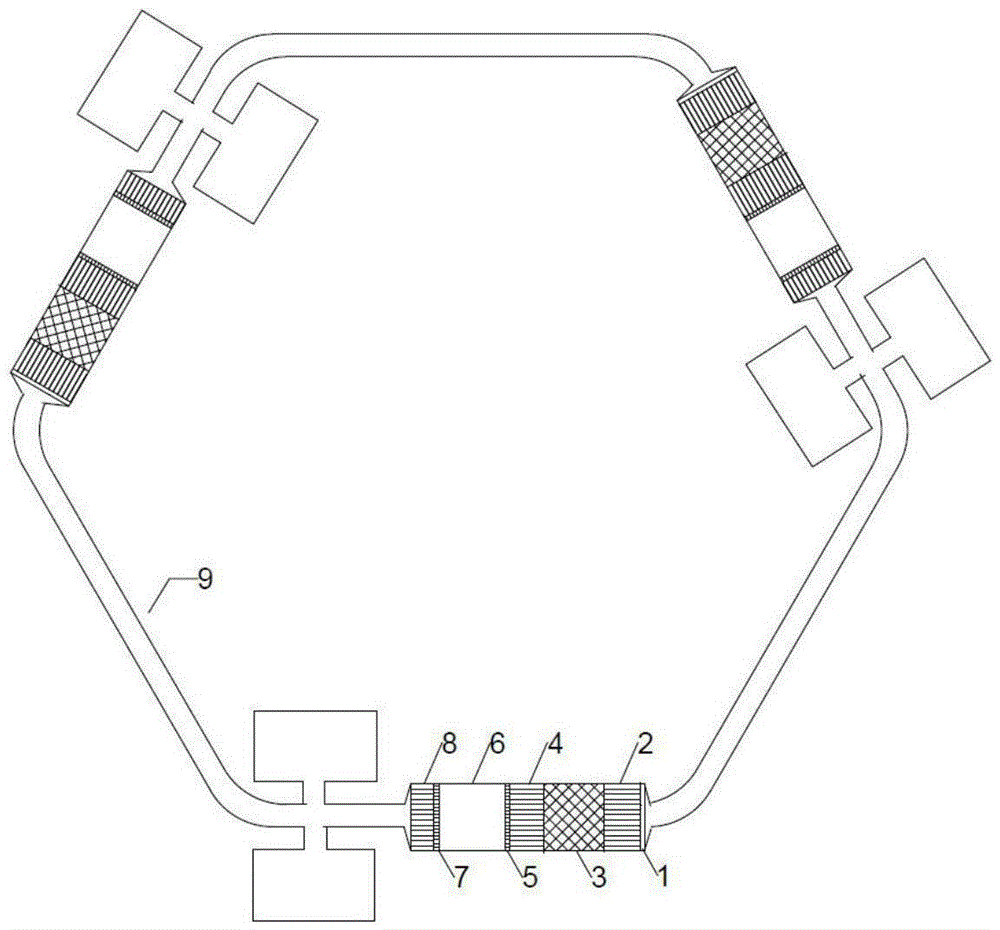

[0035] Figure 5 It is a structural schematic diagram of a multi-stage traveling wave thermoacoustic engine system (embodiment 2) for cascade utilization of high-temperature flue gas waste heat of the present invention. Such as Figure 5 As shown, the multi-stage traveling wave thermoacoustic engine system in this embodiment 2 is composed of 6 thermoacoustic engine units with the same structure and different sizes; the thermoacoustic engine units at all levels are connected end to end through resonance tubes 9 with different diameters Loop structure, each stage of thermoacoustic engine unit is in the traveling wave phase in the loop structure; each stage of thermoacoustic engine unit is connected in sequence by DC suppressor 1, main cooler 2, regenerator 3, heating 4, high temperature end layer fluidization element 5, thermal buffer pipe 6, room temperature end layer fluidization element 7 and secondary cooler 8;

[0036] Among them, the size of #1 to #6 thermoacoustic engin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com