Design method of compressor noise reduction structure

A design method and compressor technology, applied in the field of compressors, can solve the problems of difficult to ensure the same sound pressure amplitude and phase of the muffler, strong impact, flapping noise, easy impact on the motor, etc., to achieve low cost, reduce eddy current noise and impact , the effect of noise reduction and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The design method of the noise reduction structure of the compressor provided by the present invention will be described in detail below in conjunction with the embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

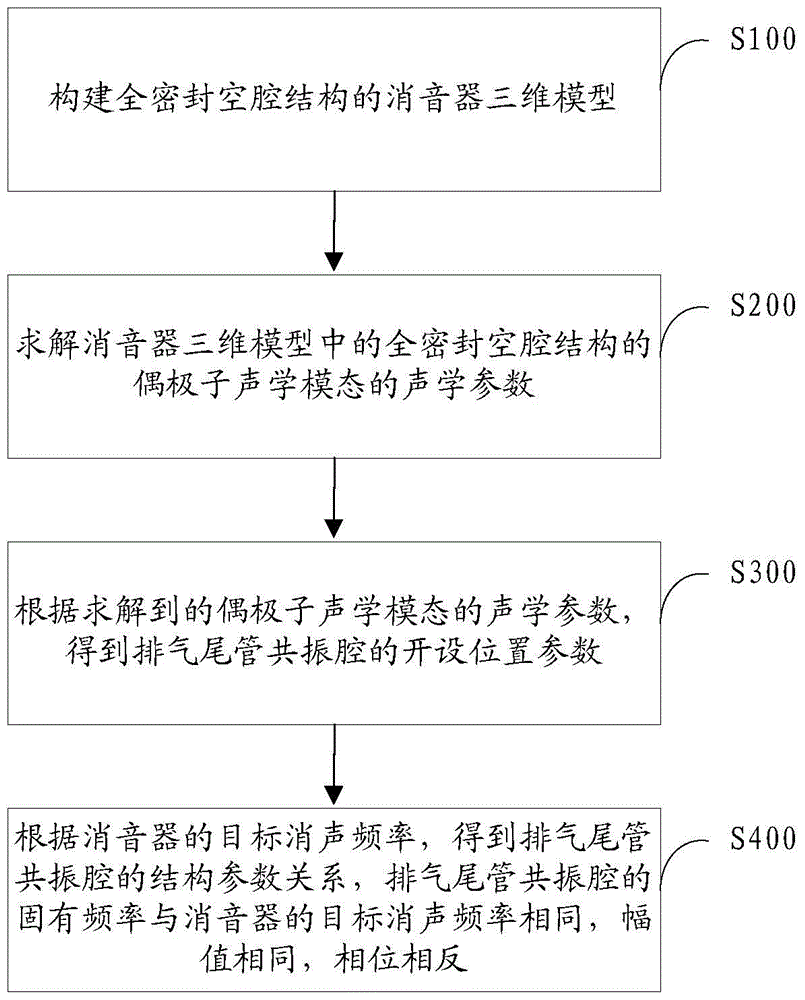

[0030] see figure 1 , the design method of compressor sound-absorbing structure provided by the present invention, comprises the following steps:

[0031] S100, Construct a 3D model of a muffler with a fully sealed cavity structure.

[0032] In step S100, the construction of the three-dimensional model of the muffler with a fully sealed cavity structure can be realized by using three-dimensional modeling software (for example, Pro / Engineer software developed by American Parametric Technology Company or Solidworks software developed by American Solidworks Company, etc.), and the realization process is now There are technologies, so I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com