Ultrasonic detection system and detection method for hollow axle of EMU

A hollow axle and detection system technology, which is applied to the analysis of solids using sonic/ultrasonic/infrasonic waves, can solve the problem of not being able to display in real time, and achieve the effects of low artificial dependence, enhanced detection ability, and low misjudgment rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] 1. The technical conditions of an ultrasonic inspection system for hollow axles of EMUs

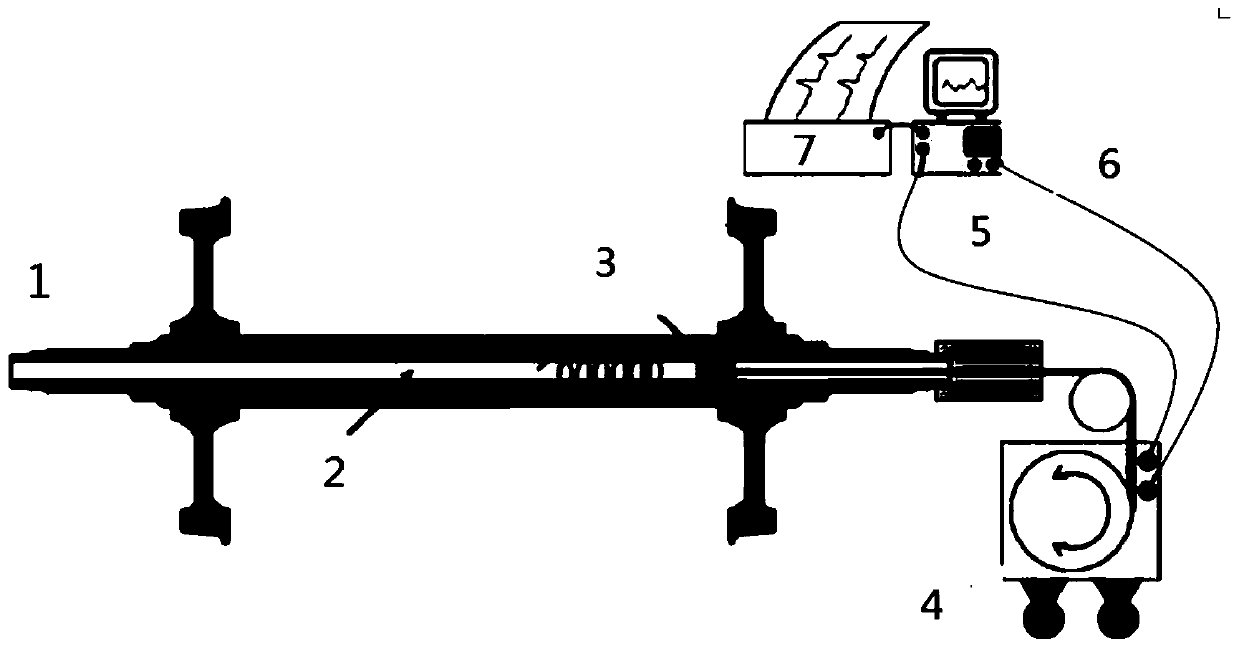

[0042] In actual engineering, this technical condition is applicable to the ultrasonic inspection system for hollow axles of EMUs. Scanning pitch setting range: 5mm; Scanning speed setting range: 60r / min; The power supply voltage of the system is AC220V, and the power supply voltage of UT equipment and motor control module is DC12V; The main sound beam scanning range: The axle of the train is 55~2220mm from the shaft end ; Periodic pulse trigger angle setting range: 0.5°~5°; gate threshold setting range: full range 0%~100%; fuel tank couplant temperature range: 18℃~50℃; system detection range: outer surface, near surface and Inside the hollow shaft; detection defect types: circumferential cracks, longitudinal cracks, other internal defects.

[0043] 2. A specific implementation of an ultrasonic inspection system for hollow axles of EMUs

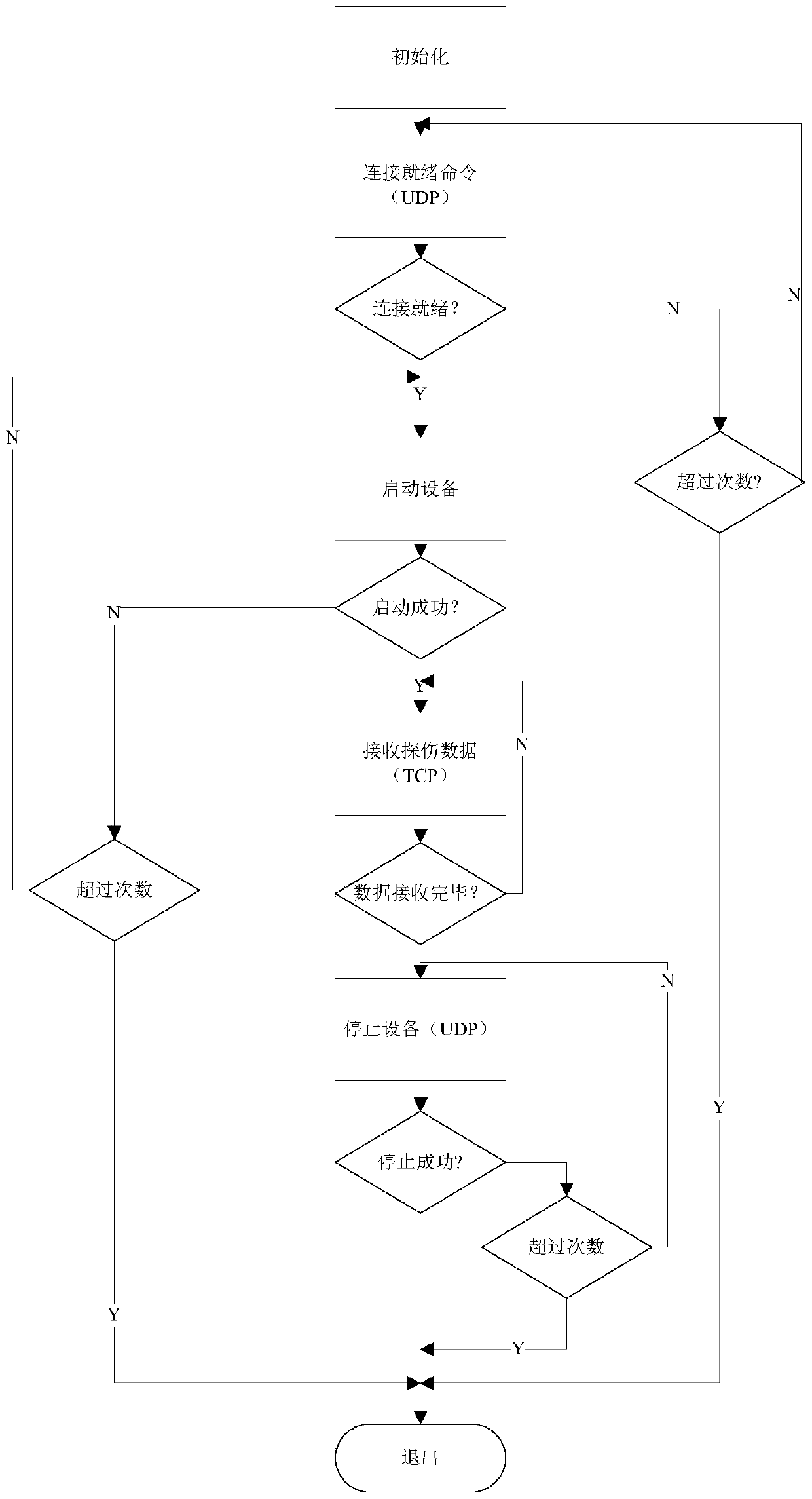

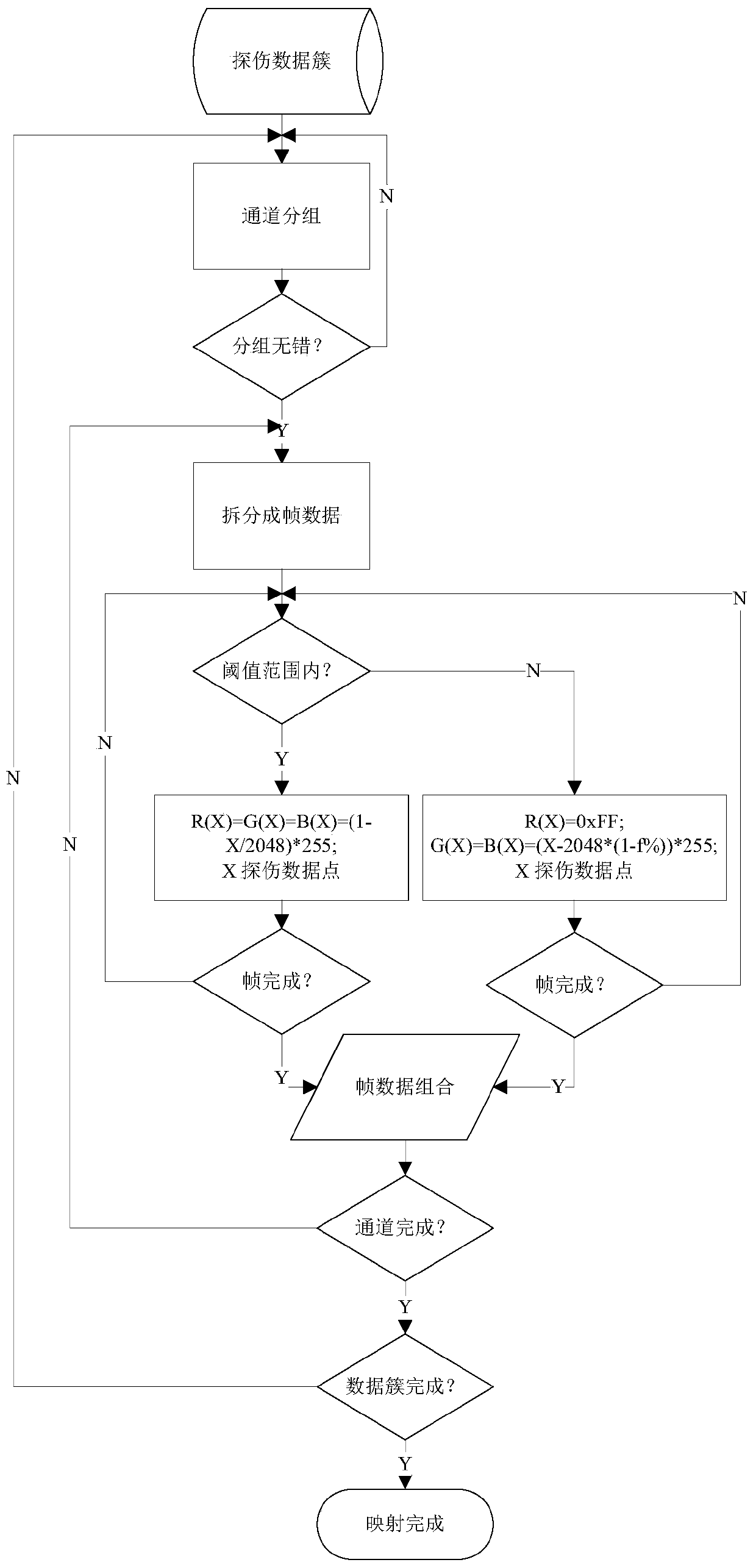

[0044] Such as figure 1 , 12 As shown, the hollo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com