Constant-temperature constant-humidity box for electrostatic spinning and method for realizing constant temperature and constant humidity

A technology of constant temperature and humidity box and electrospinning, which is applied in the direction of non-electric variable control, instrument, control/adjustment system, etc., can solve the problems of vibration and noise, and achieve the effect of low vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

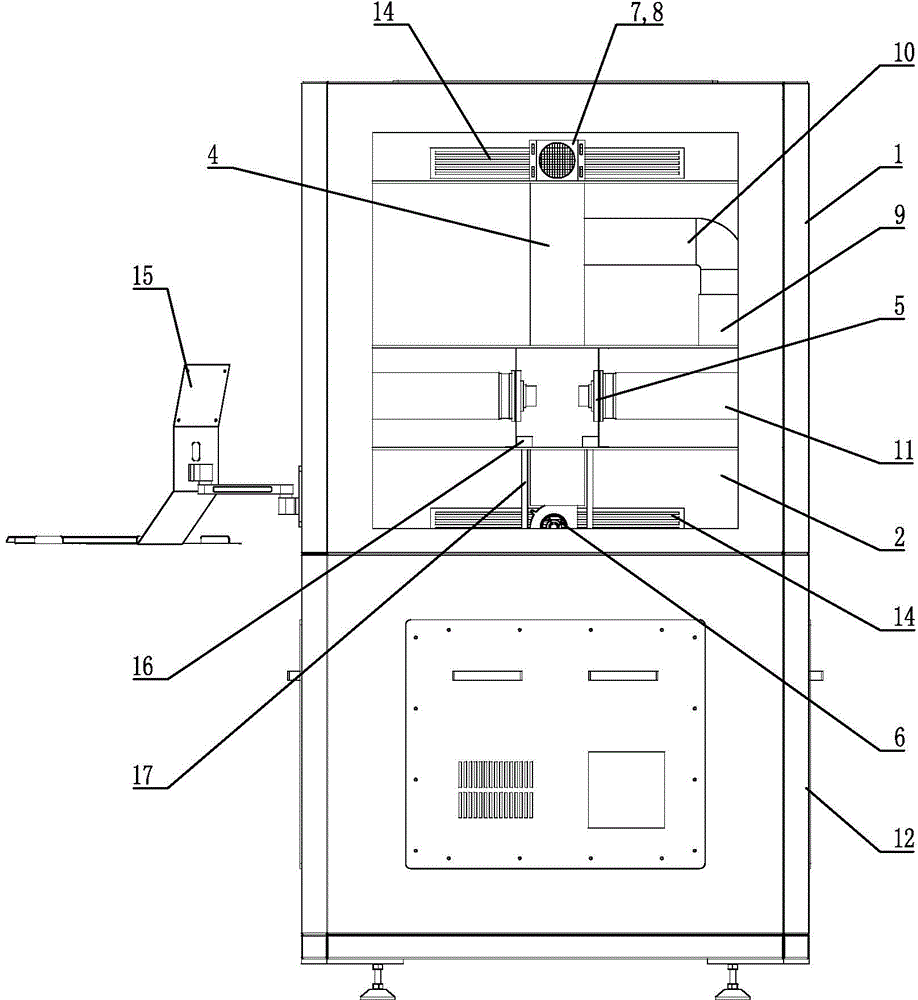

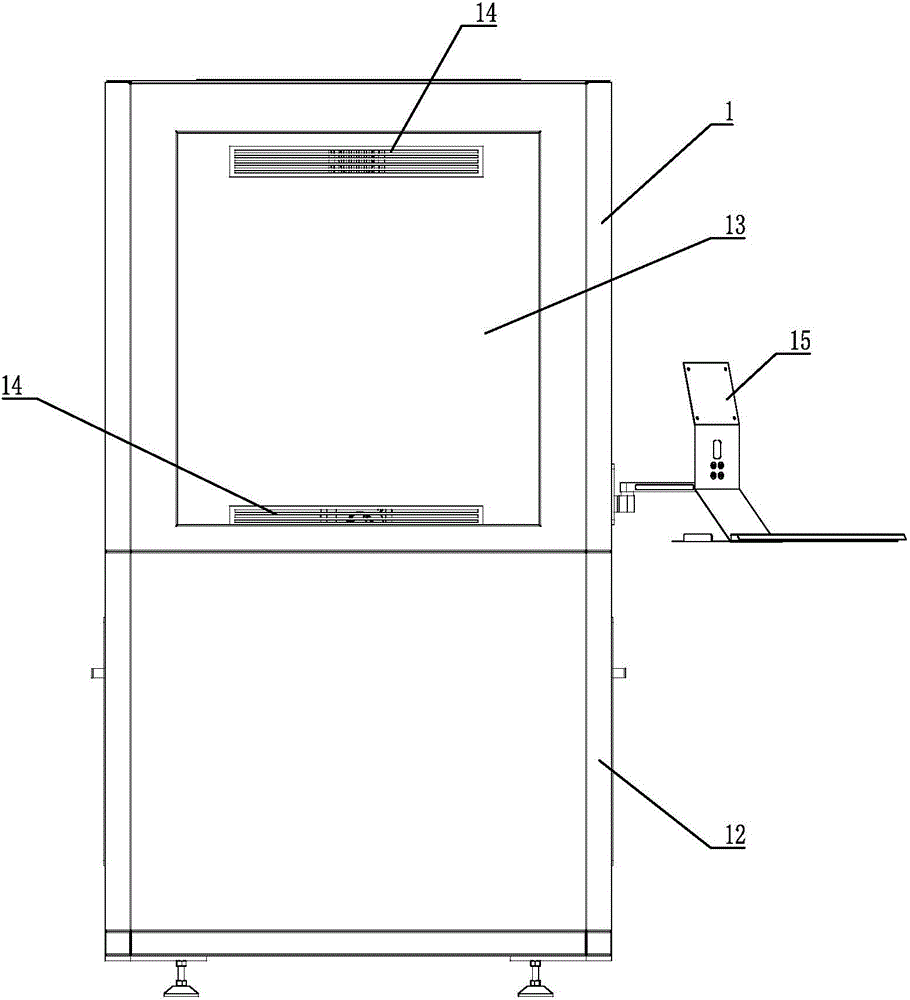

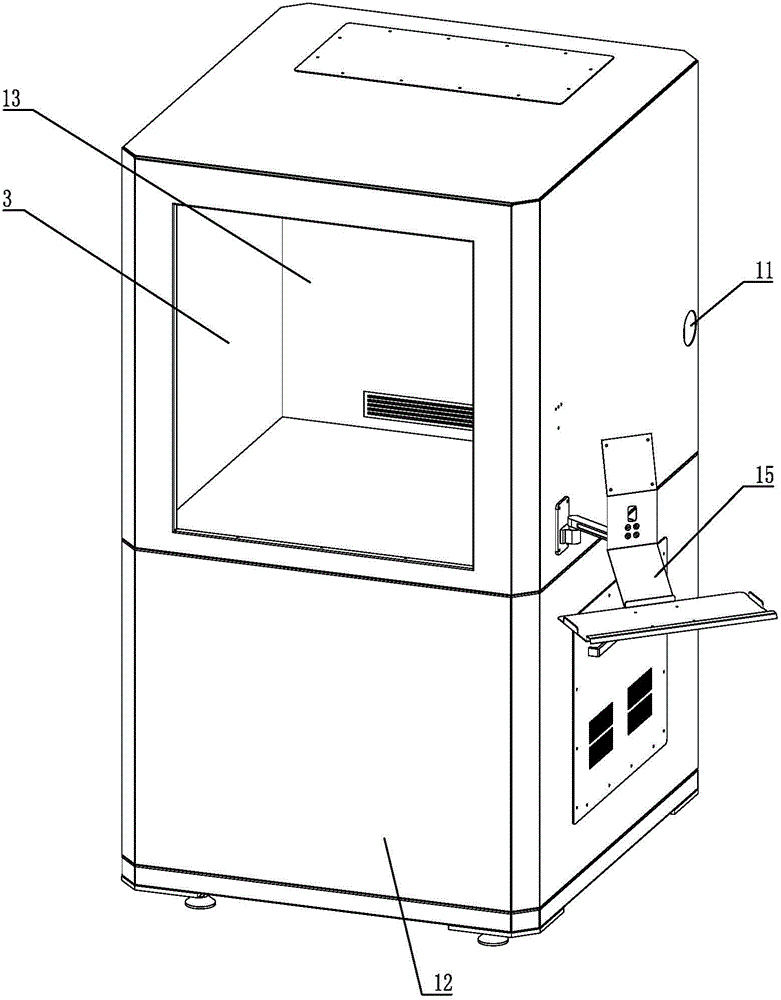

[0022] Such as Figure 1 to Figure 4 The shown constant temperature and humidity box suitable for electrospinning includes a box body 1 and a numerical control box 12 connected below the box body 1 . The box body 1 is hollow to form an inner cavity, and a vertical partition 13 is installed in the inner cavity, so as to divide the inner cavity into a processing chamber 3 at the front and a working chamber 2 at the rear. Observation windows (observation windows are not shown in the figure) are installed on the two opposite surfaces of the shell of the cabinet 1 and the partition 13, so as to facilitate the observation of the working and processing conditions inside the cabinet 1. Both the top and the bottom of the partition 13 are grooved to form a ventilation hole 14 connecting the working chamber 2 and the processing chamber 3 .

[0023] In order to ensure a constant temperature during operation and in the processing chamber 3 , an insulating layer is filled between the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com