High-voltage capacitor charging device based on super-capacitor cascading

A technology of supercapacitors and high-voltage capacitors, which is applied in the direction of battery circuit devices, circuit devices, electrical components, etc., can solve the problems of system volume, cost increase, and failure rate increase, so as to save volume and cost, reduce charging current, and failure rate. low rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

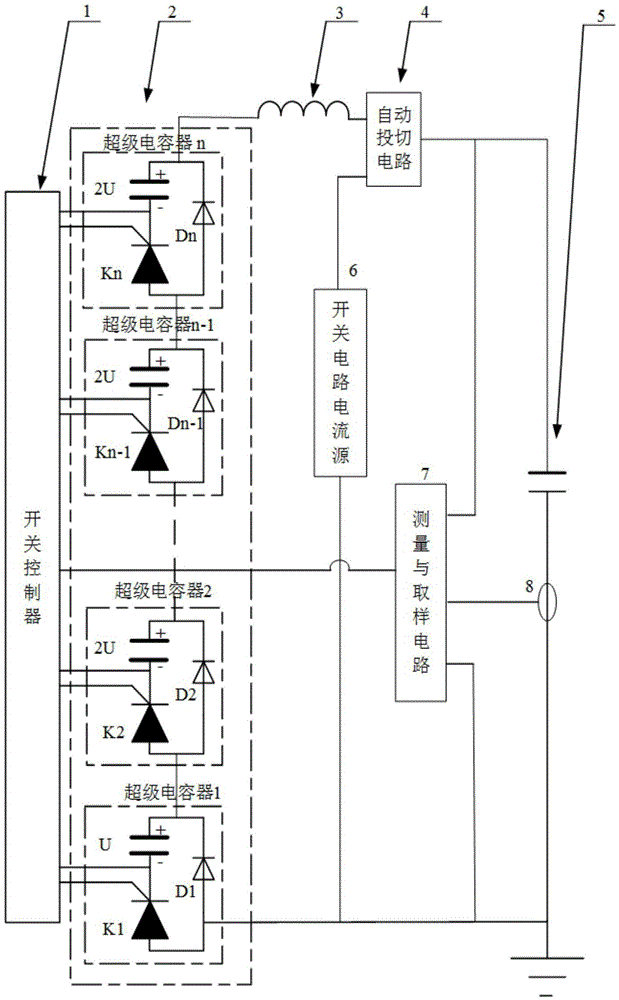

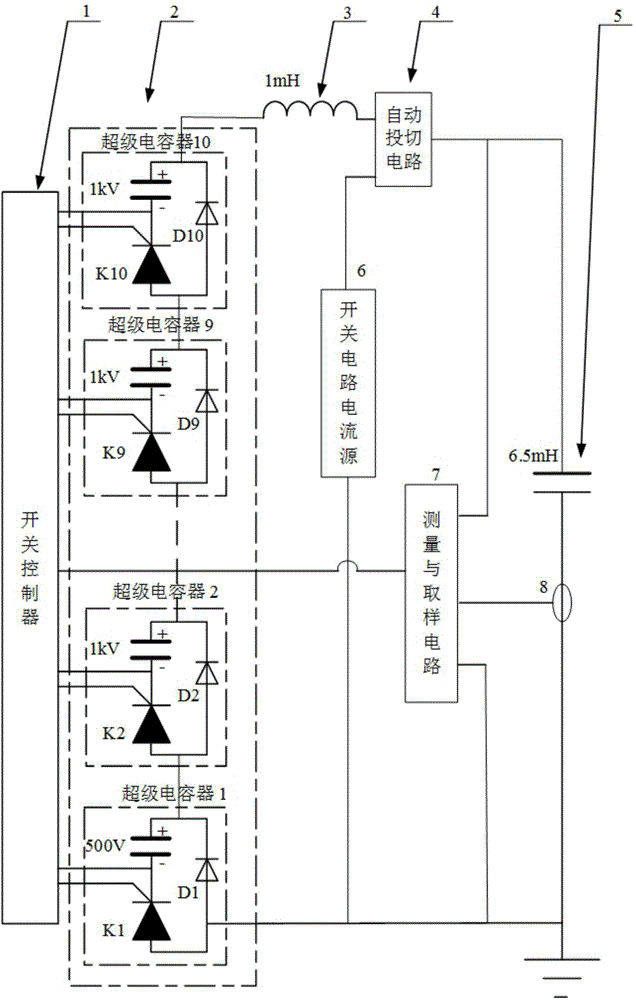

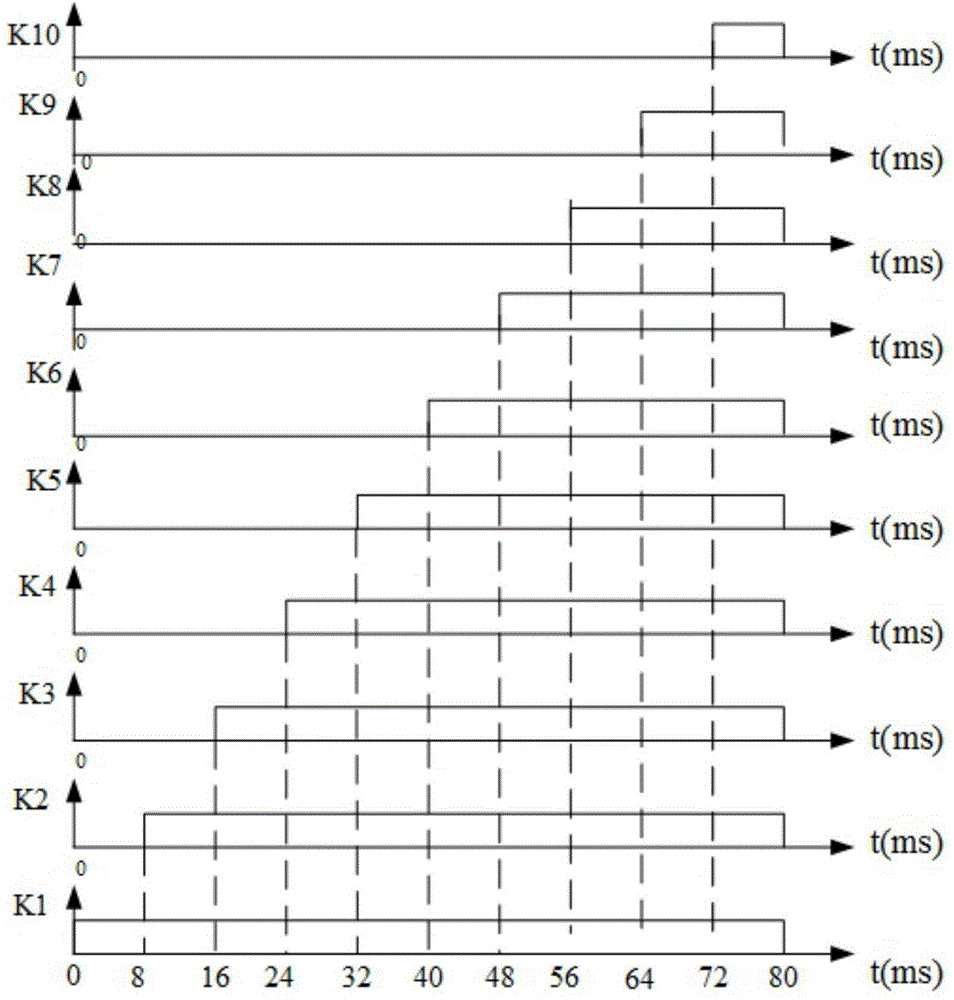

[0026] Such as figure 1 As shown, the high-voltage capacitor charging device of the present invention is composed of 8 parts: control system 1, supercapacitor bank cascade system 2, current-limiting inductor 3, automatic switching circuit 4, high-voltage capacitor 5, switching circuit current source 6, measurement and Sampling circuit 7, current measuring coil 8.

[0027] The high-voltage side of the supercapacitor bank cascading system 2 is connected in series with the current-limiting inductor 3 and then connected to the No. 1 input terminal of the automatic switching circuit 4, and the low-voltage side of the supercapacitor cascading system 2 is grounded; each unit in the supercapacitor bank cascading system 2 Lead out two ends respectively: the negative end of the supercapacitor and the trigger end of the IGBT, which are respectively conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com