An engine start-stop system based on double rotor motor and its working method

A dual-rotor motor and start-stop system technology is applied to the arrangement of multiple prime movers, power devices, and air pressure power devices of a general power device. It can solve the problems of complex systems, scattered components, and failure to integrate, and achieve The effect of small size, compact structure and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

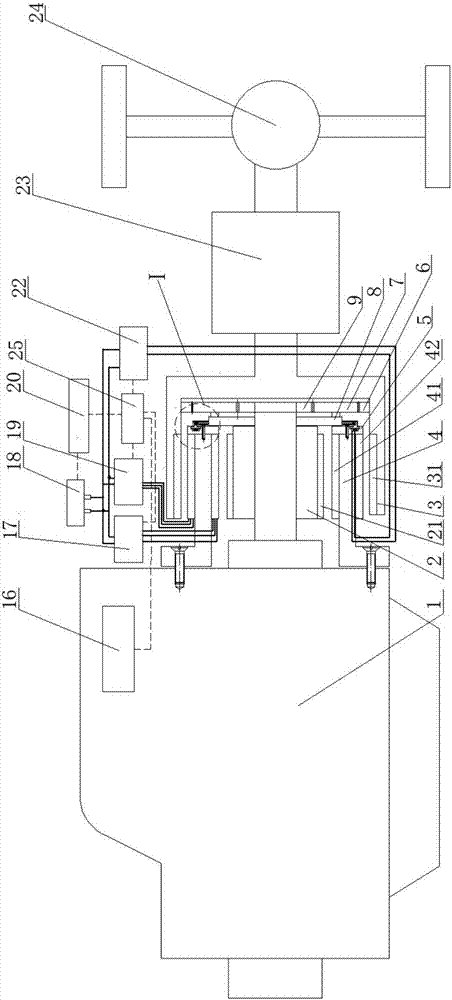

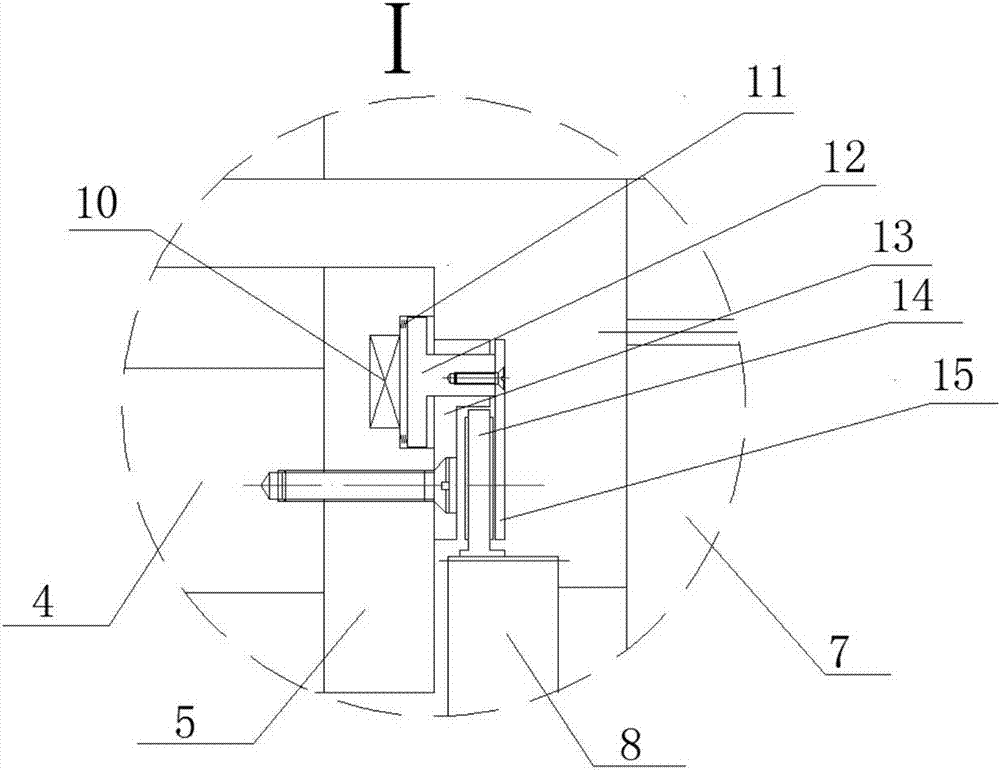

[0037] Such as figure 1 As shown, an engine start-stop system of the present invention mainly includes an engine 1, a double-rotor motor, a planetary gear mechanism, an electromagnetic clutch, a composite power supply, and a drive control system.

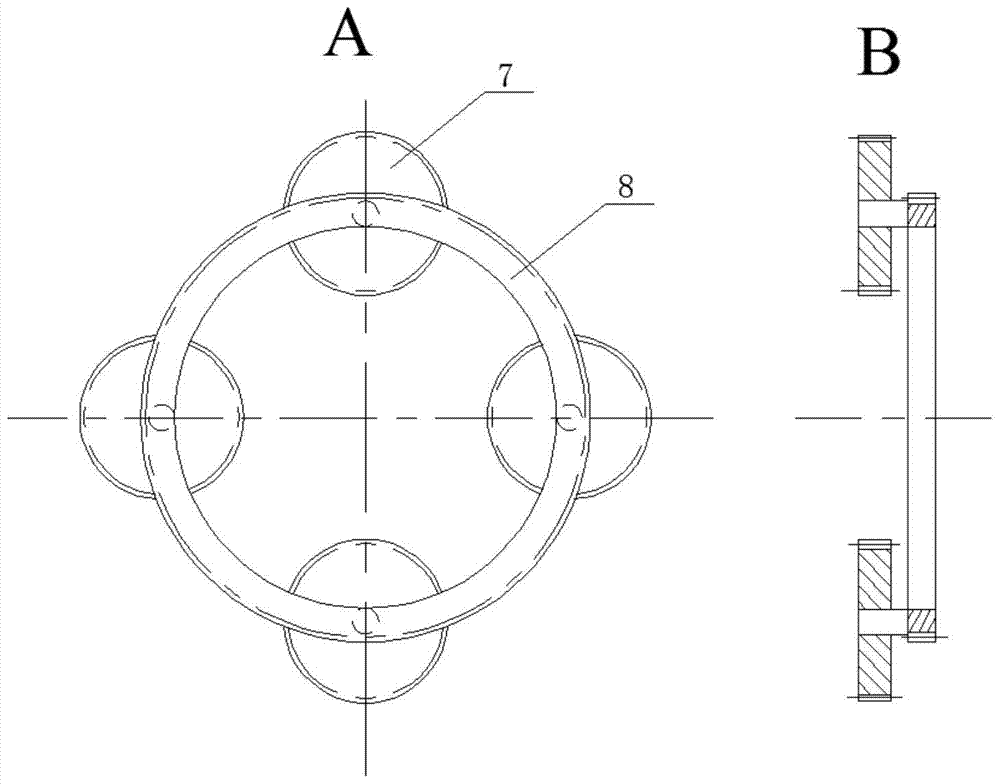

[0038] The dual-rotor motor includes an inner rotor 2 , an outer rotor 3 and a stator 4 in the middle. The rotating shaft of the inner rotor 2 is connected with the output shaft of the engine and rotates synchronously. Simultaneously, the sun gear 9 of the planetary gear mechanism is also contained on the rotating shaft of the inner rotor 2, and the two also rotate synchronously. The rotating shaft of the outer rotor 3 is connected with the gearbox input shaft and rotates synchronously. The outer rotor 3 is embedded with a ring gear 6, and the ring gear 6 and the outer rotor 3 also rotate synchronously.

[0039] The stator 4 of the dual-rotor motor is in the shape of a barrel with a skirt, and the skirt has bolt holes, which are c...

Embodiment 2

[0055] On the basis of Embodiment 1, the present invention also provides a working method of an engine start-stop system based on a dual-rotor motor.

[0056] This working method includes:

[0057] (1) The engine starts. When the power of the composite power supply is sufficient, the speed requirement of the vehicle is not high, and the outer motor of the dual-rotor motor can meet the power demand of the vehicle, the outer motor of the dual-rotor motor drives the vehicle. Neither its engine worked. When the power of the composite power supply drops to the point that it cannot meet the power supply demand of the external motor of the dual-rotor motor, the power supply detection circuit detects the signal that the power storage of the composite power supply is insufficient, and transmits the signal to the control unit, and the control unit sends a drive to the internal motor drive circuit Signal, the internal motor works, and the internal motor drives the engine to rotate at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com