Buoyancy, portable and automatic device for clearing floating impurities on water surface

A water surface floating and automatic removal technology, applied in the directions of grease/oily substance/float removal device, water/sewage treatment, water/sludge/sewage treatment, etc. Scraping equipment investment, high operation and maintenance costs, labor and labor, etc., to achieve low operation and maintenance costs, good application value and promotion value, and improve the effect of effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

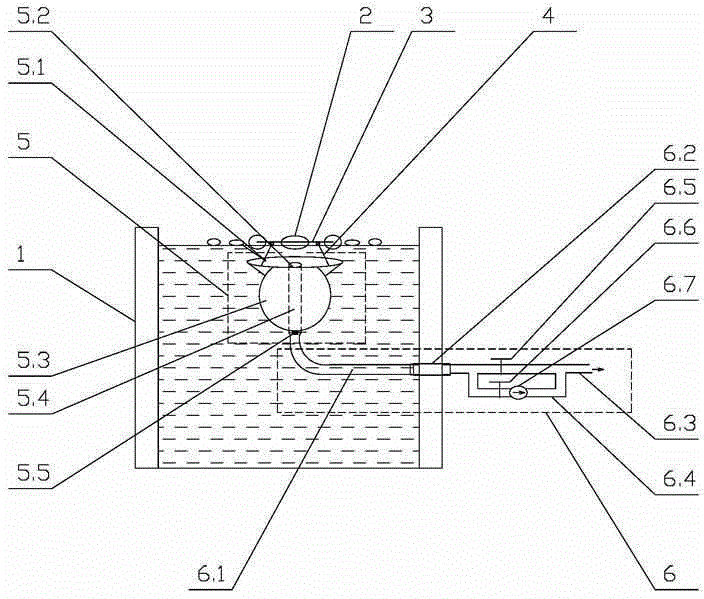

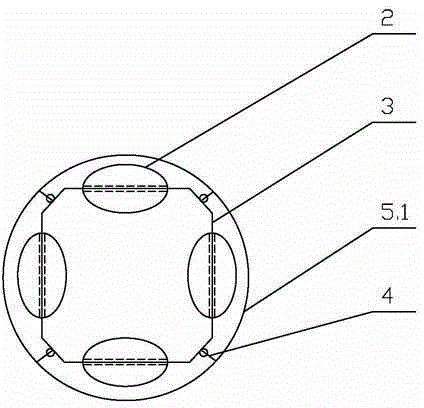

[0033] Such as figure 1 , image 3 As shown, this kind of buoyancy type, portable water surface floating debris automatic removal device can collect floating debris such as sludge, which includes:

[0034] 4 connected buoyancy balls 2 floating on the water surface in the pool 1;

[0035] The dirt collection device 5 installed under the water surface in the pool 1;

[0036] An adjustable, fixed and positioned connecting device 4 connecting the buoyancy ball 2 and the dirt collecting device 5;

[0037] The sewage discharge device 6 installed below the dirt collection device 5;

[0038] The dirt collection device 5 includes a collector 5.1 with a mud discharge hole 5.2, a fully-closed cavity floating ball 5.3 connected to and located below the collector 5.1, and a first sewage discharge device that is installed in the fully-closed cavity floating ball 5.3. Pipe 5.4, counterweight 5.5 at the bottom of the first blowdown pipe 5.4.

[0039] With this design, only a small water ...

Embodiment 2

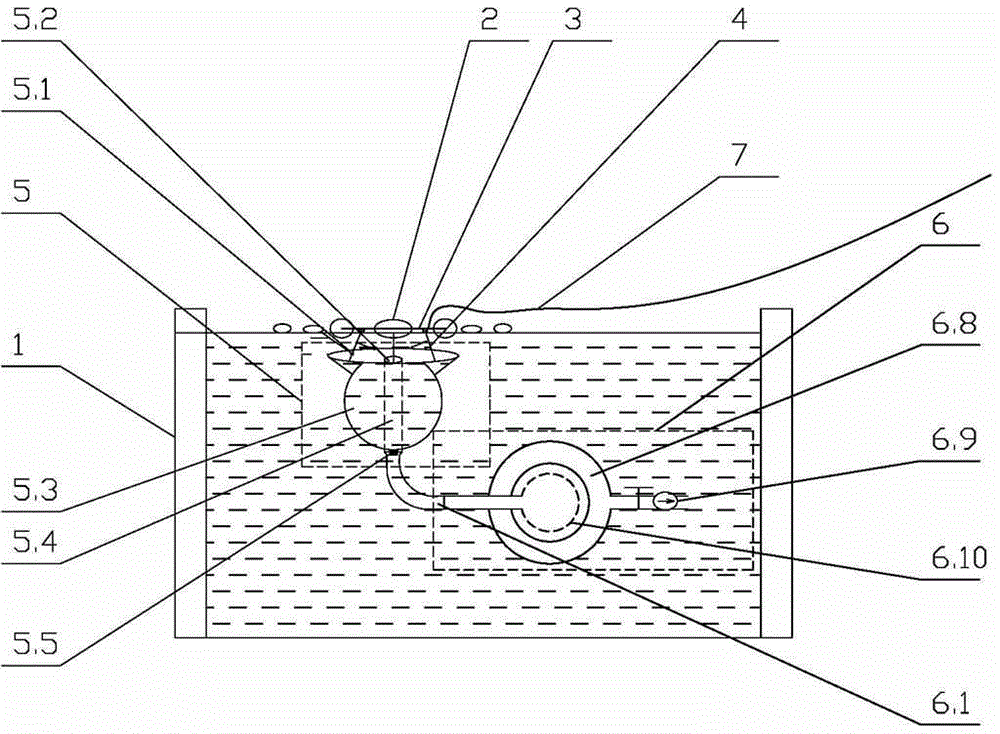

[0049] Such as figure 2 , Figure 4 As shown, this a kind of buoyancy type, portable water surface floating sundry automatic removal device is used for collecting larger-sized floating sundries such as leaves, plastic bags.

[0050] Wherein, the connection device 4 adopts a height-adjustable soft chain, and the soft chain can adjust the edge of the collector 5.1 to a height of 10-20 mm from the sewage surface. With such a design, it can be adjusted to any position that needs to remove debris within the above height range as needed, and the height adjustment is very convenient; and the use effect is better, and it is more conducive to collecting larger-sized floating objects such as leaves and plastic bags.

[0051]Specifically, the sewage discharge device 6 includes a second sewage discharge pipe 6.1 arranged in the pool 1, a filter 6.8, and a mesh debris collection bag 6.10 located in the filter 6.8, and the filter 6.8 passes through the second sewage discharge pipe 6.1 Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com