Fenton-like reactor and toxic and refractory wastewater treatment device and treatment method

A reactor, Fenton's technology, applied in the field of toxic and refractory wastewater treatment, can solve the problems of affecting biological treatment effect, high operating cost, waste of alkali, etc., to improve wastewater treatment efficiency, high operation stability, and improve mass transfer efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: class Fenton reactor structure

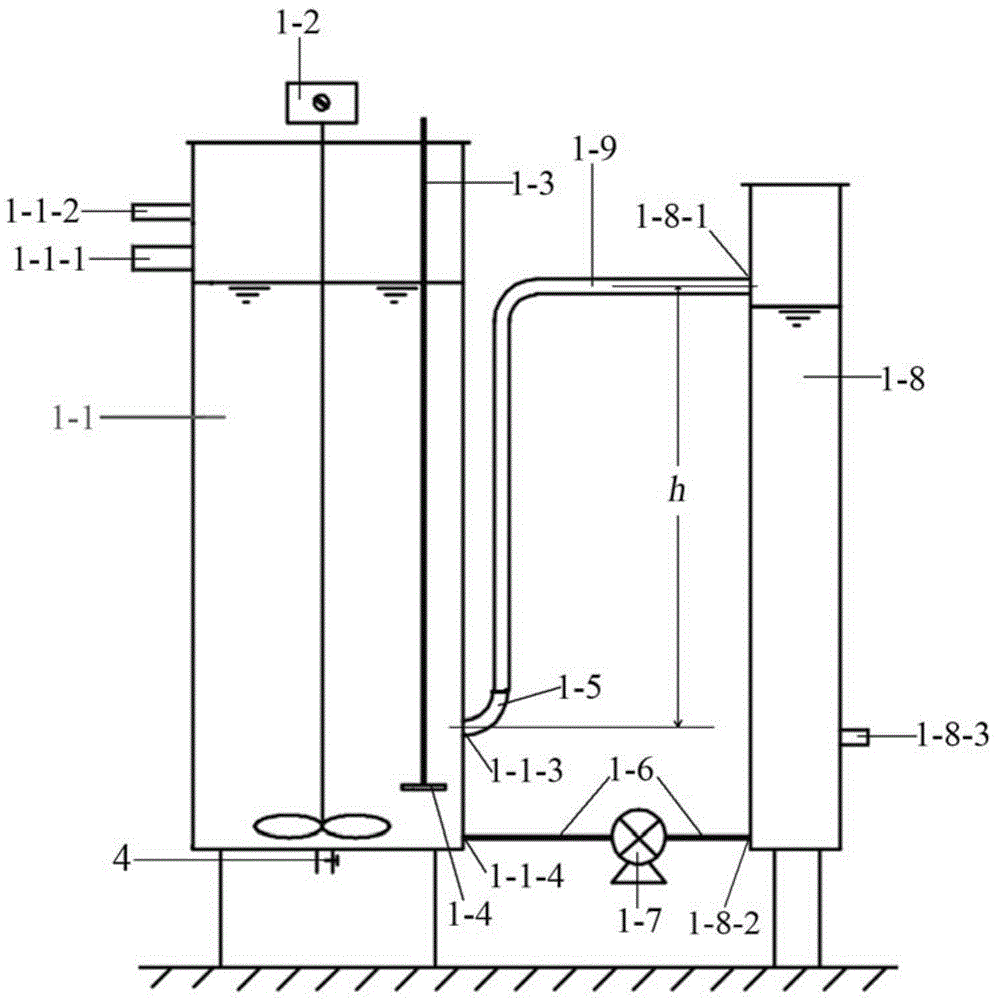

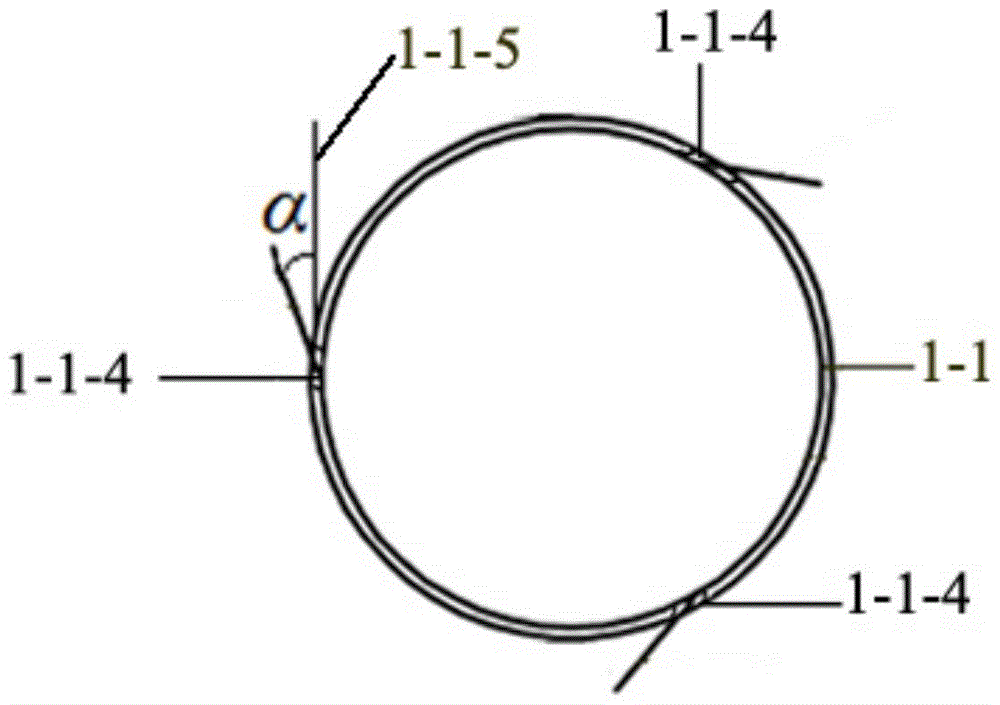

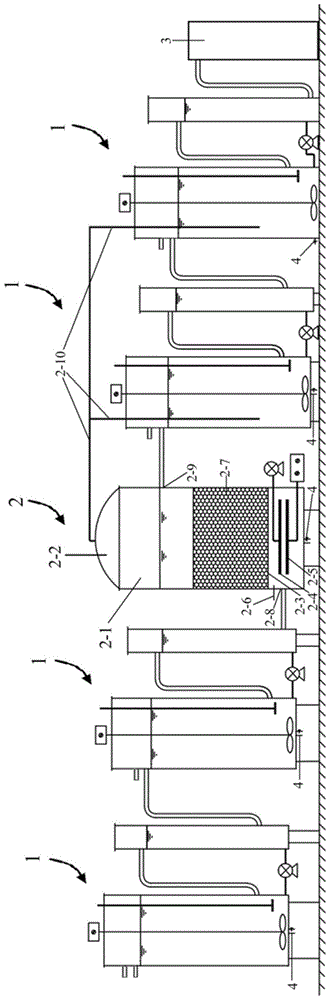

[0040] In this embodiment, the structure of the Fenton-like reactor used to treat toxic and refractory wastewater is as follows figure 1 As shown, the reaction tank 1-1 is included, and the micron-sized iron-copper bimetallic particles are housed in the reaction tank and an aerator and an agitator 1-2 are installed, and the aerator is composed of an air duct 1-3 and an aeration head 1 -4 composition, also includes return tank 1-8, return pipe 1-6, return pump 1-7 and curved elbow 1-5;

[0041] The reaction tank is a cylindrical body with a closed lower end, the bottom of the reaction tank or the lower part of the side wall of the reaction tank is provided with an emptying valve 4, and the upper part of the side wall of the reaction tank is provided with a waste water inlet 1-1-1 and a dosing port 1-1-1. 1-2, and the dosing port 1-1-2 is located above the wastewater inlet 1-1-1 to be treated, and the lower part of the side ...

Embodiment 2

[0044] Embodiment 2: class Fenton reactor structure

[0045] In this embodiment, the structure of the Fenton-like reactor used to treat toxic and refractory wastewater is as follows figure 1 As shown, the reaction tank 1-1 is included, and the micron-sized iron-copper bimetallic particles are housed in the reaction tank and an aerator and an agitator 1-2 are installed, and the aerator is composed of an air duct 1-3 and an aeration head 1 -4 composition, also includes return tank 1-8, return pipe 1-6, return pump 1-7 and curved elbow 1-5;

[0046] The reaction tank is a cylindrical body with a closed lower end, the bottom of the reaction tank or the lower part of the side wall of the reaction tank is provided with an emptying valve 4, and the upper part of the side wall of the reaction tank is provided with a waste water inlet 1-1-1 and a dosing port 1-1-1. 1-2, and the dosing port 1-1-2 is located above the wastewater inlet 1-1-1 to be treated, and the lower part of the side ...

Embodiment 3

[0049] Embodiment 3: class Fenton reactor structure

[0050] In this embodiment, the structure of the Fenton-like reactor used to treat toxic and refractory wastewater is as follows figure 1 As shown, the reaction tank 1-1 is included, and micron-sized zero-valent iron particles are housed in the reaction tank, and an aerator and an agitator 1-2 are installed, and the aerator is composed of an air duct 1-3 and an aeration head 1- 4 components, including return tank 1-8, return pipe 1-6, return pump 1-7 and curved elbow 1-5;

[0051] The reaction tank is a cylindrical body with a closed lower end, the bottom of the reaction tank or the lower part of the side wall of the reaction tank is provided with an emptying valve 4, and the upper part of the side wall of the reaction tank is provided with a waste water inlet 1-1-1 and a dosing port 1-1-1. 1-2, and the dosing port 1-1-2 is located above the wastewater inlet 1-1-1 to be treated, and the lower part of the side wall of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com