Rotating Membrane Bio-Airlift Loop Reactor

A technology of circulating reactor and biogas, applied in the field of MBR membrane bioreactor, can solve the problems of high maintenance cost and high energy consumption, and achieve the effect of prolonging the service life of the membrane, increasing the processing load, and removing the pollution on the membrane surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

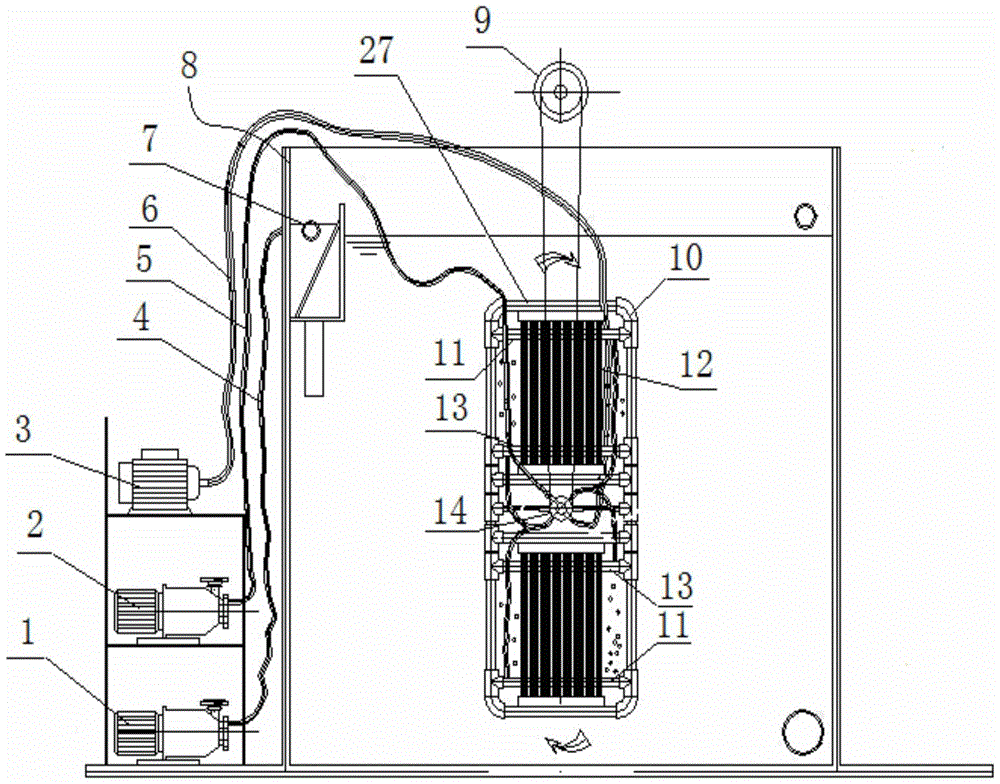

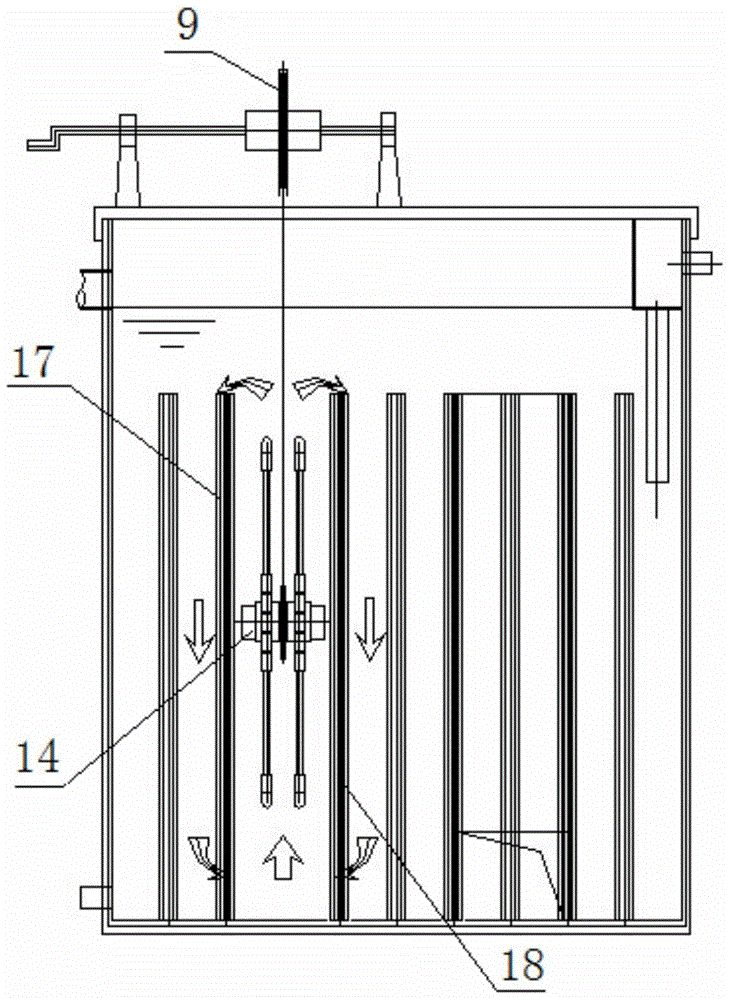

[0026] Such as Figure 1~2 As shown, the present invention comprises water suction pump 1, self-priming pump 2, electromagnetic air pump 3 and membrane filtration device, wherein water suction pump 1, self-priming pump 2, electromagnetic air pump 3 are all arranged on the outside of reactor body 8, and membrane filtration device Set in the reactor body 8, the reactor body 8 is provided with a water inlet 7, and the water suction pump 1 is connected to the water inlet 7 through the water suction hose 4, thereby introducing sewage into the water inlet 7, and in the reactor body 8 A water inlet tank with a microporous filter is provided, and the sewage is introduced into the reactor body 8 along the water inlet. The microporous filter is used to filter large particles in the sewage to prevent damage to the surface of the membrane filament and affect the water pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com