Fluorine-containing epoxy curing agent capable of normal-temperature curing, and preparation and application thereof

An epoxy curing agent and room temperature curing technology, which is applied in the field of chemical and chemical synthesis, can solve the problems of reduced transparency, phase separation, poor compatibility, etc., and achieve the effect of excellent mechanical properties and reducing the degree of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

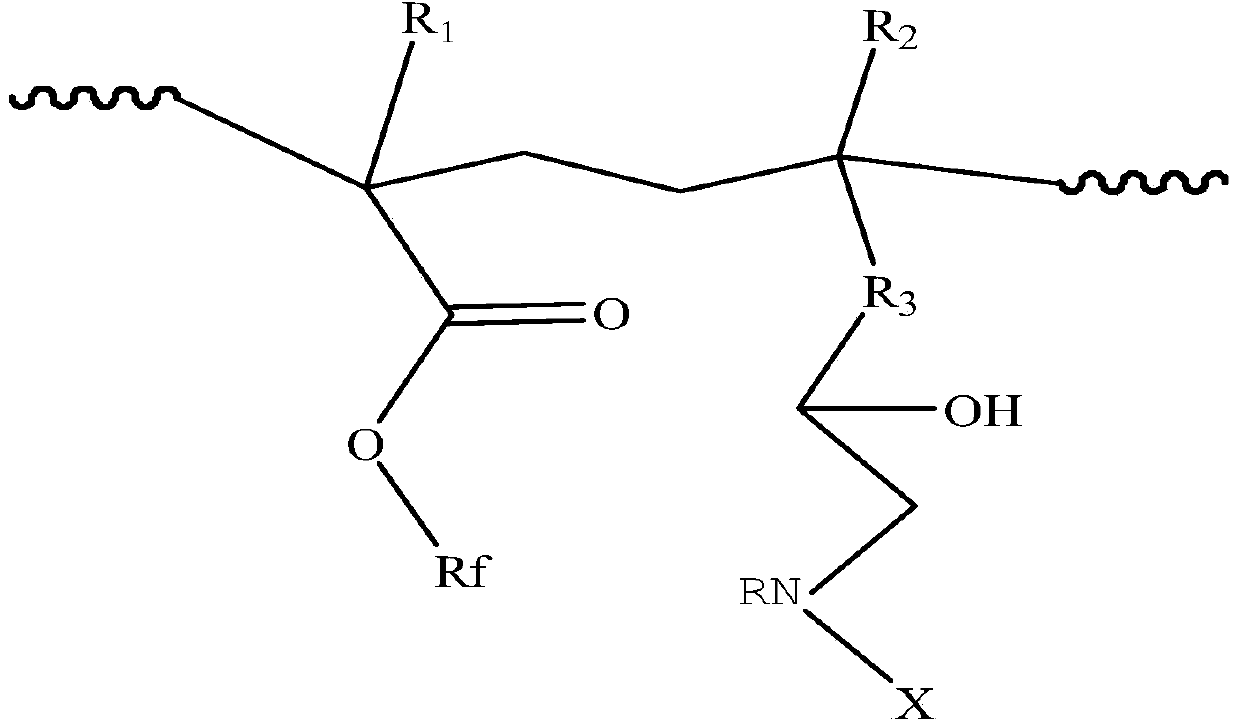

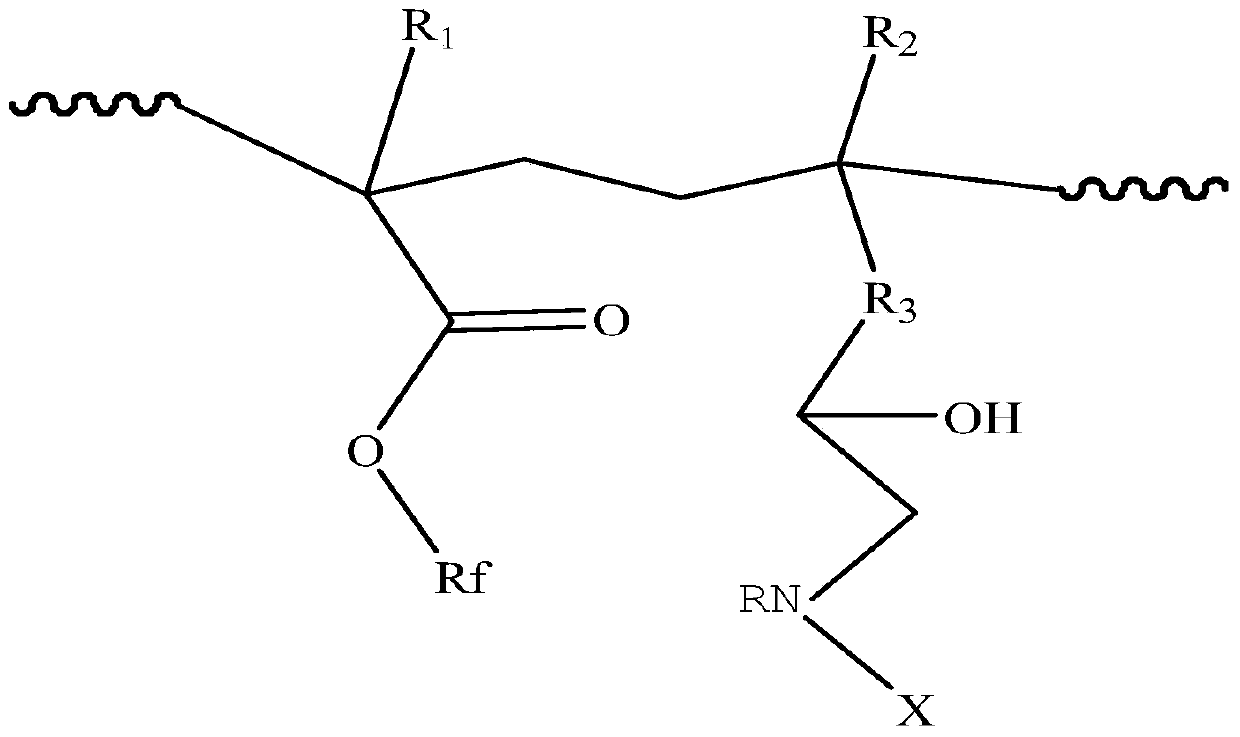

Method used

Image

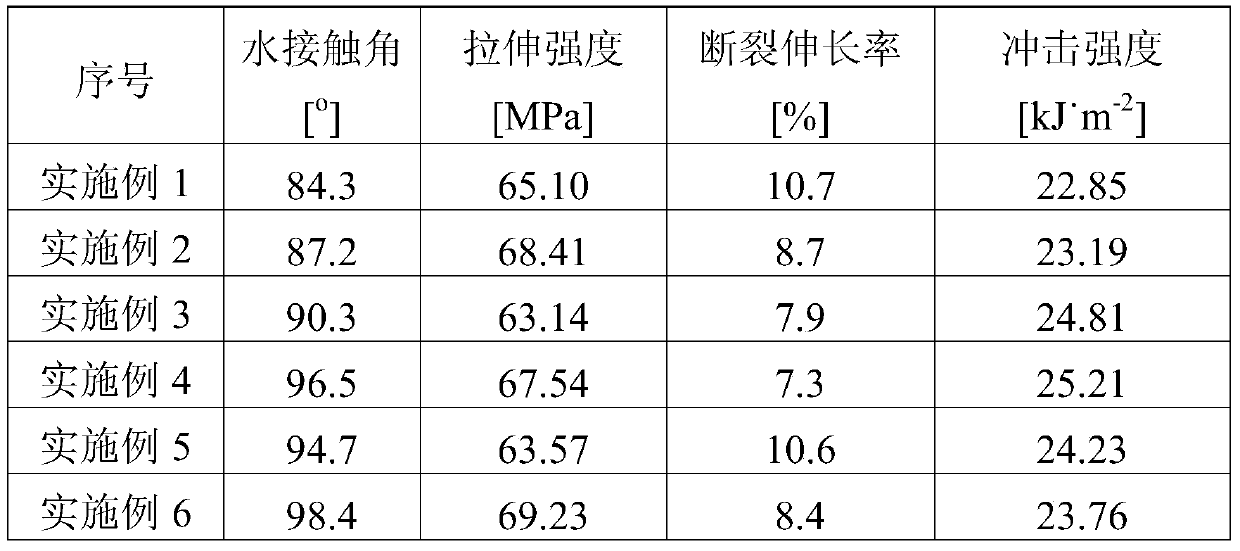

Examples

Embodiment 1

[0028] (1) Preparation of fluorine-containing epoxy random copolymer solution: add 30 mass parts of trifluoroethyl acrylate, 60 mass parts of glycidyl methacrylate and 80 mass parts of methyl ethyl ketone, azobisisoheptyl 0.5 parts by mass of nitrile, mixed uniformly, heated to 78° C. and stirred for 12 hours to obtain a fluorine-containing epoxy random copolymer solution.

[0029] (2) Preparation of fluorine-containing epoxy curing agent curable at room temperature: Take 150 parts by mass of the fluorine-containing epoxy random copolymer solution prepared in step (1), add 120 parts by mass of tetraethylenepentamine, and react at 10°C 12h. The reaction mixture was distilled under reduced pressure, the solvent was evaporated, the residue was poured into an evaporating dish, and placed in an oven for vacuum drying to obtain a fluorine-containing epoxy curing agent curable at room temperature.

[0030] (3) Mix ERL-422180 parts by mass, 5 parts by mass of fluorine-containing epox...

Embodiment 2

[0032] (1) Preparation of fluorine-containing epoxy random copolymer solution: add 40 parts by mass of hexafluorobutyl methacrylate, 80 parts by mass of allyl glycidyl ether and 150 parts by mass of butyl acetate in a container, and azo 1.5 parts by mass of diisoheptanonitrile, mixed uniformly, heated to 100° C. and stirred for 8 hours to obtain a fluorine-containing epoxy random copolymer solution.

[0033] (2) Preparation of fluorine-containing epoxy curing agent that can be cured at room temperature: Take 150 parts by mass of the fluorine-containing epoxy random copolymer solution prepared in step (1), add 40 parts by mass of diethylenetriamine, and react at 0°C 12h. The reaction mixture was distilled under reduced pressure, the solvent was evaporated, the residue was poured into an evaporating dish, and placed in an oven for vacuum drying to obtain a fluorine-containing epoxy curing agent curable at room temperature.

[0034] (3) 10 parts by mass of ERL-4229, 10 parts by ...

Embodiment 3

[0036] (1) Preparation of fluorine-containing epoxy random copolymer solution: add 50 parts by mass of dodecafluoroheptyl methacrylate, 100 parts by mass of glycidyl acrylate and 150 parts by mass of toluene in a container, and benzoyl peroxide 2 parts by mass, mixed evenly, heated up to 110° C. and stirred for 8 hours to obtain a fluorine-containing and epoxy-containing random copolymer solution.

[0037](2) Preparation of fluorine-containing epoxy curing agent curable at room temperature: Take 150 parts by mass of the fluorine-containing epoxy random copolymer solution prepared in step (1), add 52 parts by mass of triethylenetetramine, and react at 30°C for 9 hours . The reaction mixture was distilled under reduced pressure, the solvent was evaporated, the residue was poured into an evaporating dish, and placed in an oven for vacuum drying to obtain a fluorine-containing epoxy curing agent curable at room temperature.

[0038] (3) 90 mass parts of bisphenol A type epoxy res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com