A kind of neutral ink water-soluble emulsified moisturizing lubricant and preparation method thereof

A neutral ink, water-soluble technology, applied in ink, applications, household appliances, etc., can solve the problems of neutral ink product deterioration, damage to the stability system of neutral ink, and affect the development of neutral ink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

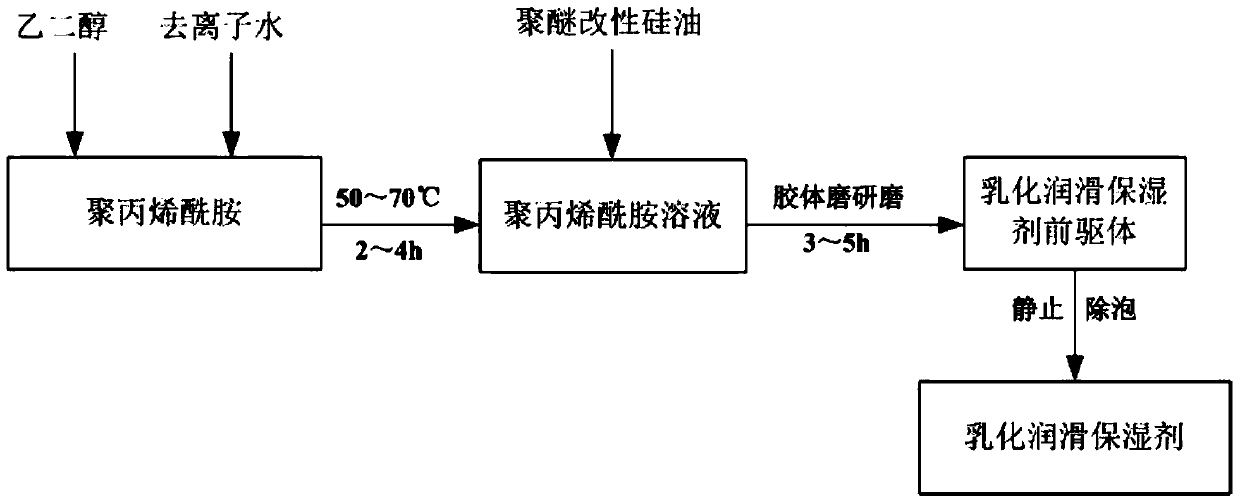

[0072] The second aspect of the present invention provides a kind of preparation method of described neutral ink water-soluble emulsified moisturizing lubricant, wherein, comprise the steps:

[0073] (a) providing the components described in the present invention, and dissolving the water-soluble polyacrylamide in the mixed solvent;

[0074] (b) adding water-soluble polyether modified silicone oil to the system obtained in step (a);

[0075] (c) Grinding, dispersing and filtering the solution obtained in step (b) to obtain the water-soluble emulsified moisturizing lubricant for the neutral ink.

[0076] In a specific embodiment of the present invention, the grinding in the step (c) is carried out using a colloid mill, wherein the grinding is carried out in the colloid mill for 3-5 hours.

[0077] application

[0078] The third aspect of the present invention provides an application of the neutral ink water-soluble emulsified moisturizing lubricant in neutral ink.

Embodiment approach

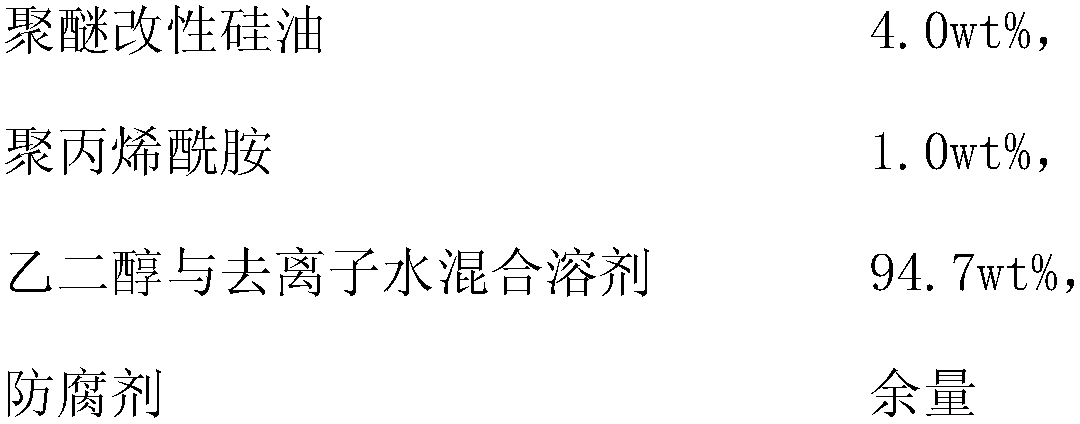

[0080] In a preferred embodiment of the present invention, wherein, the neutral ink water-soluble emulsified moisturizing lubricant consists of the following components:

[0081] Water-soluble polyether modified silicone oil 1.5-4.0wt%,

[0082] Water-soluble polyacrylamide is 0.5-1.0wt%,

[0083] The mixed solvent is 94.7~97.6wt%, and the mixed solvent is a mixed solvent of ethylene glycol and deionized water; or the mixed solvent is a mixed solvent of polyethylene glycol with a low degree of polymerization and deionized water, and the low polymerization The weight-average molecular weight of polyethylene glycol is not higher than 800;

[0084] Preservatives are the balance;

[0085] And the described neutral ink water-soluble emulsified moisturizing lubricant is prepared by the following method:

[0086] (a) first dissolving the water-soluble polyacrylamide in the mixed solvent;

[0087] (b) adding water-soluble polyether modified silicone oil to the system obtained in s...

Embodiment 1

[0104] First configure a mixed solvent of ethylene glycol and water with a mass ratio of 1:8, and then dissolve polyacrylamide with an average molecular weight of 100,000 in a mixed solvent of ethylene glycol and deionized water at 50°C. After stirring for 2 hours to fully dissolve, mix and disperse, add water-soluble polyether modified silicone oil with an average molecular weight of 7500 to the system, use a colloid mill to grind, mix and disperse, grind for 5 hours, then filter, and prepare neutral ink water after standing still for 72 hours Soluble emulsifying moisturizing lubricant.

[0105] The name and content of each component are as follows:

[0106]

[0107]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com