A seed crystal substrate in-situ bonding method for homoepitaxial growth of single crystal diamond

A technology for growing single crystal and homoepitaxial growth, which is applied in the directions of single crystal growth, crystal growth, single crystal growth, etc. It can solve the problem of heat conduction between the seed crystal and the metal molybdenum substrate, the deviation of the seed crystal from the optimal position, and the surface quality of the seed crystal. to avoid connection failure, simplify operation, save time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

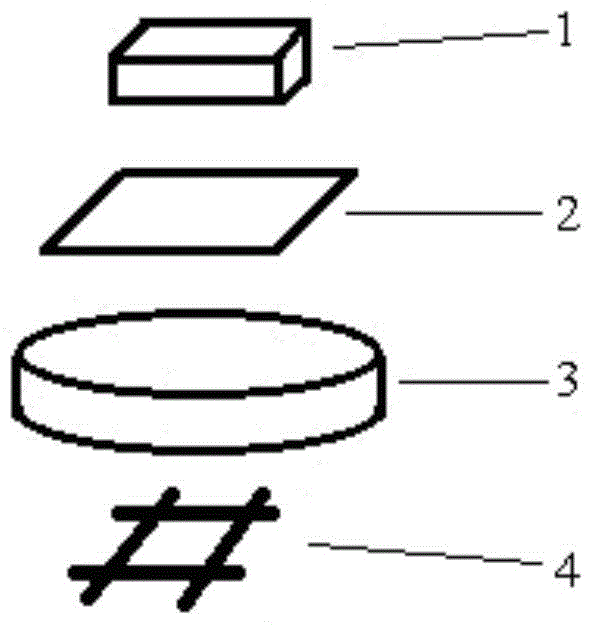

[0033] Specific implementation mode one: combine figure 1 with figure 2 Specifically explaining this embodiment, a method for in-situ connection of a seed crystal substrate for homoepitaxial growth of single crystal diamond described in this embodiment is specifically carried out according to the following steps:

[0034] 1. Cleaning: cleaning the diamond seed crystal and the metal molybdenum substrate wafer to obtain the cleaned diamond seed crystal and the cleaned metal molybdenum substrate wafer;

[0035] 2. Select gold foil: select a flat gold foil with a thickness of 20 μm to 100 μm, and cut the flat gold foil into a square piece that is 0.5 mm to 1.5 mm larger than the diamond seed crystal in length and width to obtain a welding medium;

[0036] The purity of the flat gold foil is 18K-24K;

[0037] 3. Place the sample:

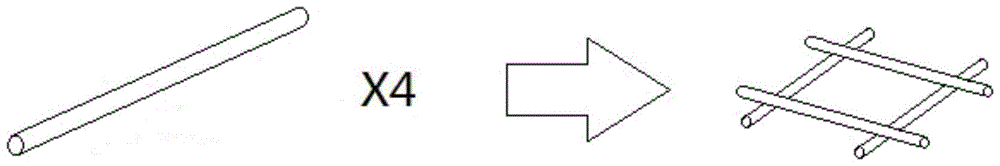

[0038] Place four metal molybdenum wires in a "well" shape to obtain a metal molybdenum wire base, place the metal molybdenum wire base on the micro...

specific Embodiment approach 2

[0055] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the diamond seed crystal and the metal molybdenum substrate wafer are cleaned, specifically according to the following steps: Under certain conditions, the diamond seed crystal and the metal molybdenum substrate wafer were washed in acetone for 15 min to 30 min, in deionized water for 15 min to 30 min, and in absolute ethanol for 15 min to 30 min to obtain the cleaned diamond seed crystal and the cleaned After the metal molybdenum substrate wafer. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0056] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the purity of the flat gold foil described in step 2 is 24K. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com