A seed crystal substrate vacuum brazing method for homoepitaxial growth of single crystal diamond

A single crystal growth, homoepitaxy technology, used in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of damaged seed crystals, poor diamond compatibility, and seed crystals deviating from the best position, to ensure quality, The effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

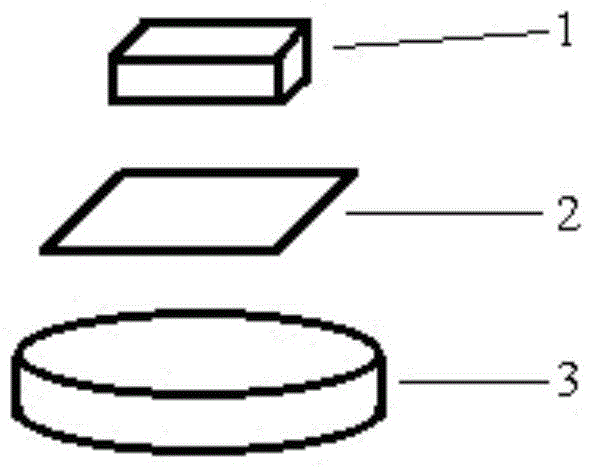

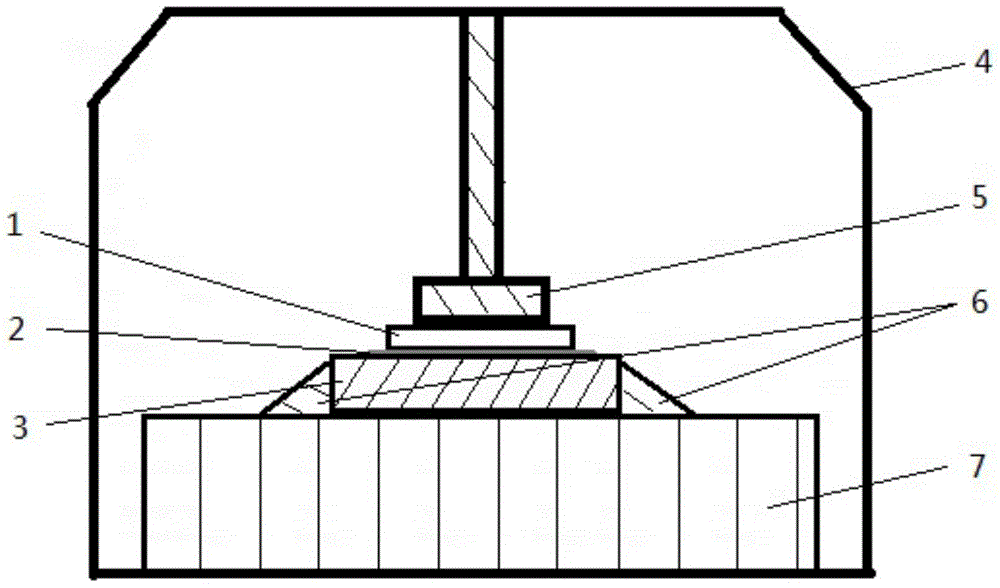

[0031] Specific implementation mode one: combine Figure 1-2 This embodiment is described in detail. The vacuum brazing method for a seed crystal substrate of homoepitaxially grown single crystal diamond described in this embodiment is specifically carried out according to the following steps:

[0032] 1. Cleaning: cleaning the diamond seed crystal and the metal molybdenum substrate wafer to obtain the cleaned diamond seed crystal and the cleaned metal molybdenum substrate wafer;

[0033] 2. Selection of welding medium: Punch the alloy with a punching machine to form a flat gold flake with a thickness of 20 μm to 100 μm, and cut the flat gold flake into a square piece that is 0.5 mm to 1.5 mm larger in length and width than the cleaned diamond seed crystal, to obtain Welding medium;

[0034] The mass percentage of Fe element in the alloy is 3%-5%, the mass percentage of Ti element is 10%-20%, the mass percentage of Cr element is 10%-25%, and the balance is Ni element;

[003...

specific Embodiment approach 2

[0049] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the diamond seed crystal is cleaned, specifically according to the following steps: under the condition of ultrasonic power of 100W-400W, the diamond seed crystal Washing in acetone for 15 min to 30 min, washing in deionized water for 15 min to 30 min, and washing in absolute ethanol for 15 min to 30 min, to obtain diamond seed crystals after washing. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0050] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the metal molybdenum substrate wafer is cleaned, specifically according to the following steps: Under certain conditions, the metal molybdenum substrate wafer is washed in acetone for 15 minutes to 30 minutes, deionized water for 15 minutes to 30 minutes, and absolute ethanol for 15 minutes to 30 minutes to obtain the metal molybdenum substrate disk after cleaning. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com