Hydrophilic polypropylene monofilament and production method thereof

A production method and hydrophilic technology, which can be applied in the direction of single-component polyolefin rayon, rayon manufacturing, filament/thread forming, etc. The effect of increasing hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The invention provides a hydrophilic polypropylene monofilament, comprising: polypropylene and a hydrophilic modification aid, the hydrophilic modification aid comprising: polypropylene grafted acrylic acid copolymer, thermoplastic elastic polyester, In the ethylene-acrylic acid copolymer, the content of the hydrophilic modification auxiliary agent is 10%-30%.

[0018] The hydrophilic polypropylene monofilament provided by the present invention is made into a monofilament through steps such as melt spinning by adding various hydrophilic modification aids to polypropylene, and the monofilament made has better hydrophilicity Performance, making the use of polypropylene monofilament wider.

[0019] Optionally, the diameter of the monofilament is 0.08-0.3mm, the strength of the monofilament is ≥3.5cN / dtex, and the elongation at break is 20%-40%; the produced hydrophilic polypropylene monofilament is thinner and has a relatively High strength and elongation at break can be ...

Embodiment 2

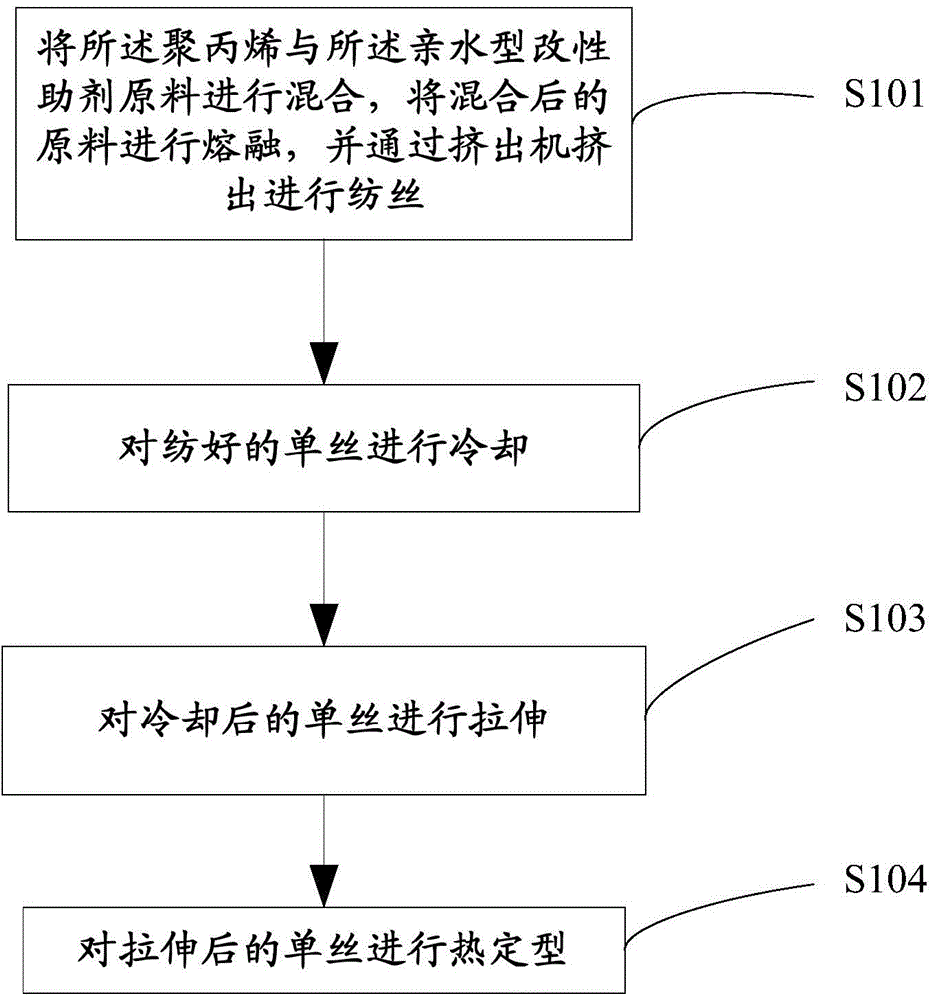

[0021] Such as figure 1 Shown, the present invention also provides a kind of production method of hydrophilic polypropylene monofilament, comprises steps:

[0022] S101: Mix the polypropylene with the hydrophilic modification auxiliary raw material, melt the mixed raw material, and extrude through an extruder for spinning;

[0023] S102: cooling the spun monofilament;

[0024] S103: Stretching the cooled monofilament;

[0025] S104: Heat setting the stretched monofilament.

[0026] The above production method mixes the raw materials, melts and spins the mixed raw materials, and cools, stretches and heat-sets the monofilaments coming out of the extruder. In each step, the monofilaments are drawn by specific temperatures and methods. Stretching and other treatments to determine the monofilament strength and elongation at break of the hydrophilic polypropylene monofilament.

[0027] Optionally, the spinning temperature in step S101 is: 285-300°C; spinning at this temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Monofilament strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com