Roller control system of rotor spinning machine

A technology of rotor spinning machine and control system, applied in spinning machine, open-end spinning machine, continuous winding spinning machine, etc., can solve problems affecting yarn quality, operation efficiency, etc., and reduce deviations opportunities, the effect of improving yarn quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

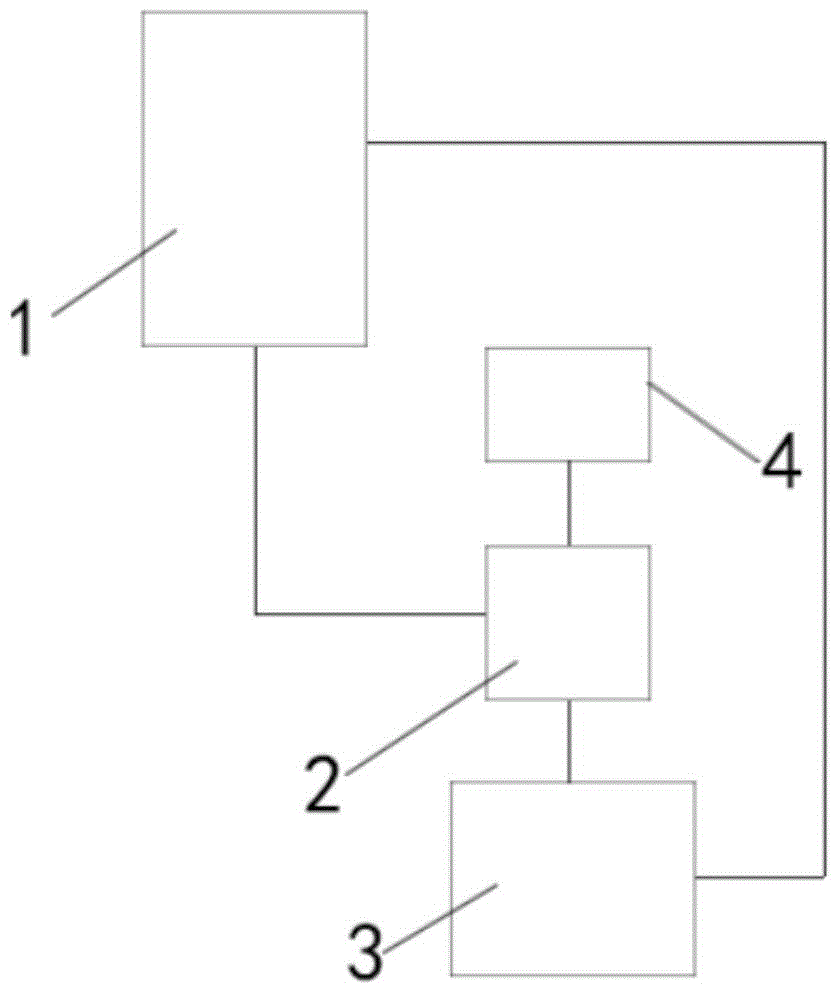

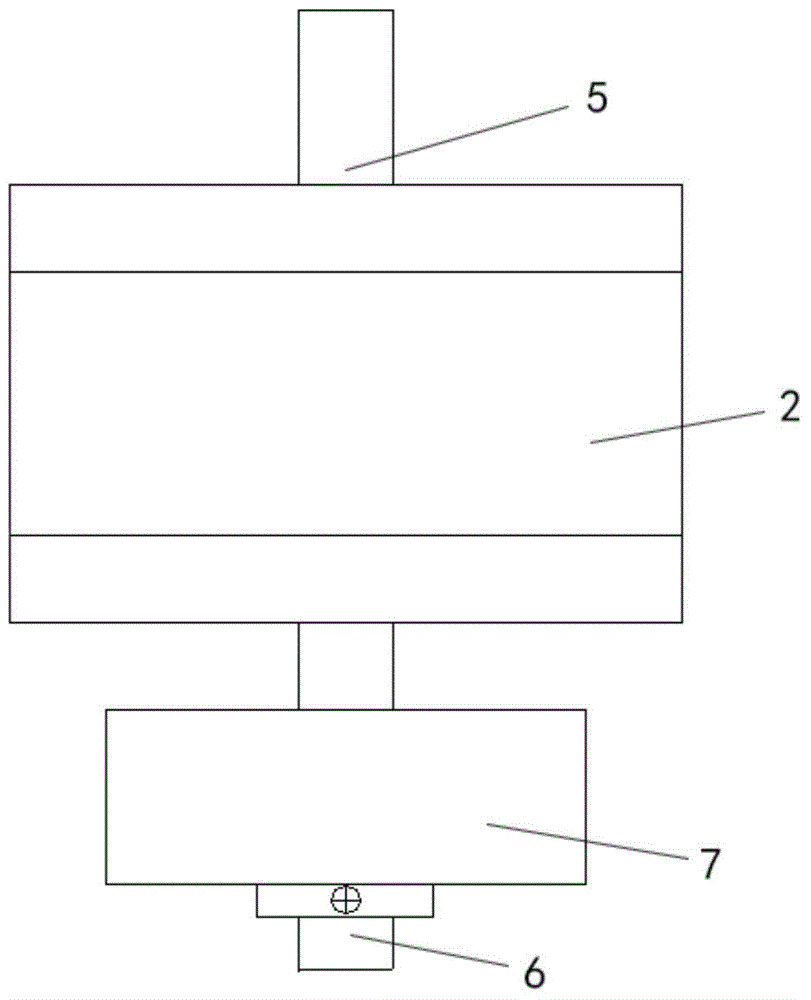

[0017] Embodiment 1, such as figure 1 Shown, the present invention comprises controller 1 and stepping motor 2, and stepping motor 2 drives roller to rotate, and controller 1 controls the work of stepping motor 2, and the front end of motor shaft 5 of described stepping motor 2 and roller shaft The transmission connection drives the roller shaft to rotate. The rear end of the motor shaft extends axially from the housing of the stepper motor 2 to form an extension shaft 6. A speed measuring device 3 is installed on the extension shaft. The speed measuring device 3 is an encoder 7. Device 7 is installed on described extension shaft 6, and encoder 7 carries out real-time monitoring to the rotating speed of motor shaft 5 of stepper motor 2, and encoder 7 carries out signal connection with described controller 1, and described controller 1 The control program of the control program is provided with a speed comparison module and a speed adjustment module. The speed measuring device ...

Embodiment approach 2

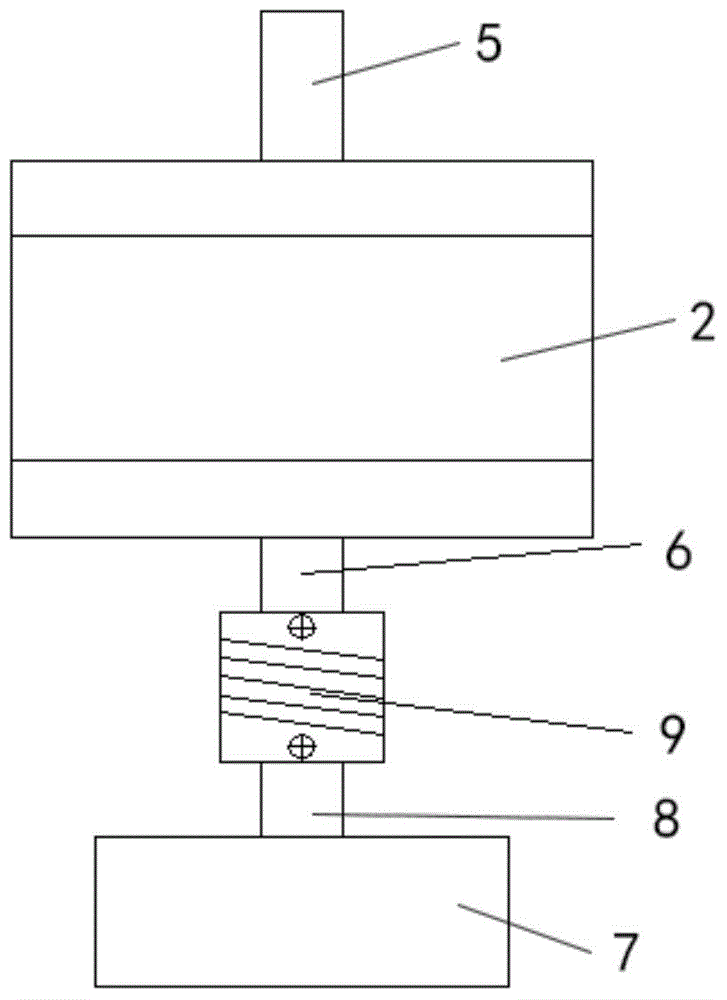

[0018] Implementation mode two, such as image 3 As shown, the encoder described in the above embodiment is installed on a rotating shaft 8 , and the rotating shaft 8 is connected with the extension shaft 6 of the motor through a coupling 9 .

Embodiment approach 3

[0019] Implementation mode three, such as Figure 4 As shown, the speed measuring device 3 described in the first embodiment above can also be composed of a code disc 10 and an induction switch, the code disc 10 is fixedly set on the extension shaft 6 of the motor shaft 5, and the induction switch is a photoelectric switch 11 , The photoelectric switch 11 is fixedly installed with the outer ring part of the code disc 10, which improves the speed detection accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com