Two-way pneumatic hot air shutoff gate

A technology for shutting off doors and hot air, applied to windows/doors, door/window accessories, power control mechanisms, etc., can solve problems such as large temperature difference of partition doors, large air ducts, easy deformation of door panels, etc., and solve the problem of loose closing , The system is simple and the operation is stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

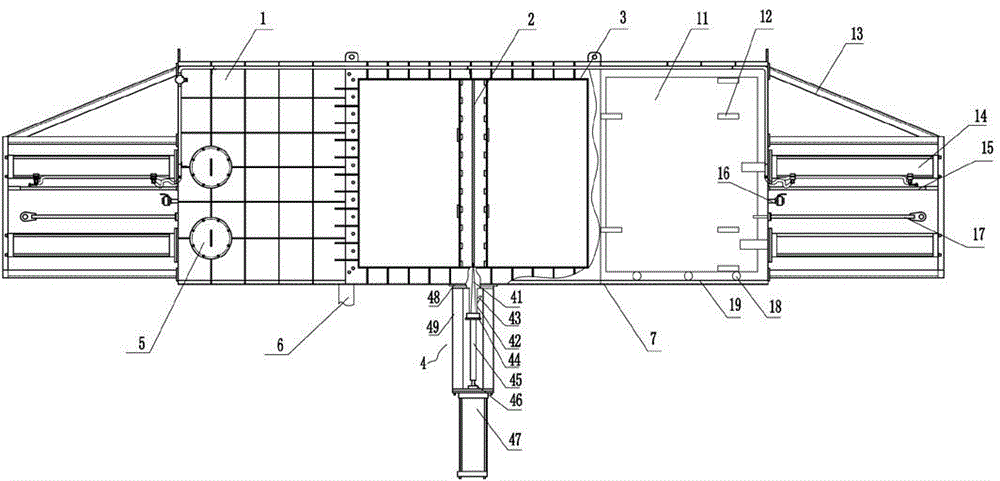

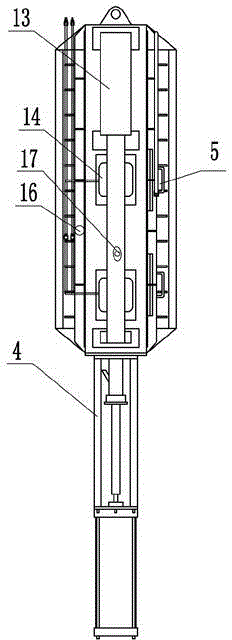

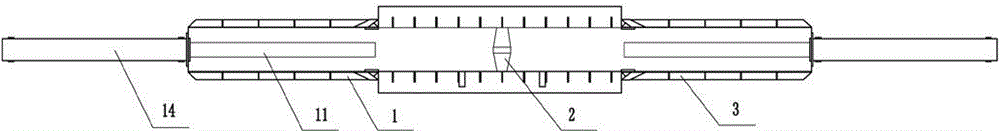

[0017] Such as figure 1 As shown, the present invention includes a frame 7, a manhole 5, a left partition door 1, a right partition door 3, a column 2 and the like. Both the left partition door 1 and the right partition door 3 include a door panel 11 , a wedge fitting unit 12 and a driving cylinder 14 . A column 2 is set in the middle of the frame 7, and the left partition door 1 and the right partition door 3 are connected into a whole through the column 2. The windward side of the column 2 is an inclined plane. There are two drive cylinders 14 for the left partition door 1 and the right partition door 3 , which jointly drive the door panels 11 . The door panel 11 is made of stainless steel plate (TS21 / L1). The driving cylinder 14 is welded on the partition door through the cylinder outer fixing bracket 13 . A limit indicator 15 is set on the drive cylinder 14 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com