Multi-mode pulse detonation engine

A detonation engine and pulse detonation technology, applied in mechanical equipment, intermittent injection devices, etc., can solve the problems of bulky structure, poor economy, and non-universal use, and achieve the effect of low process requirements, good environmental protection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

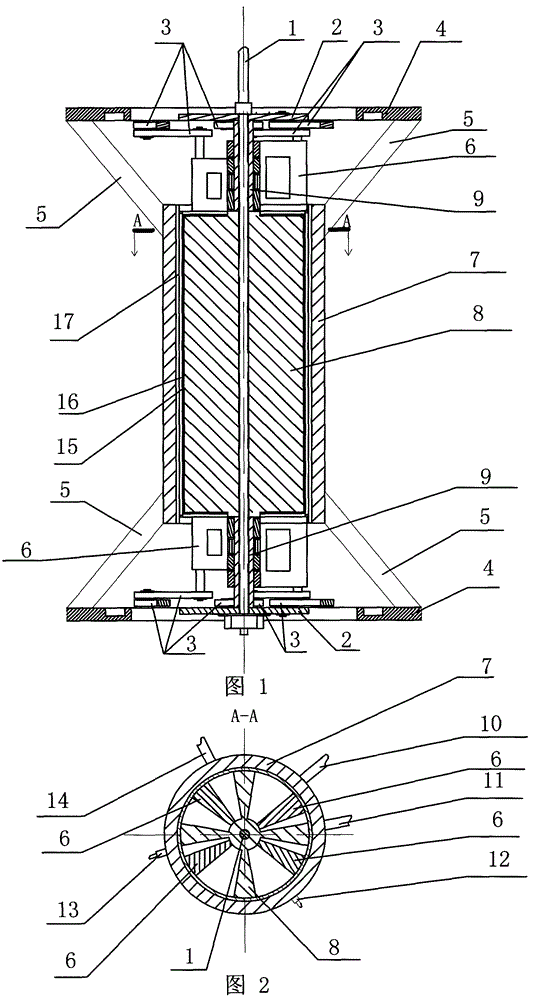

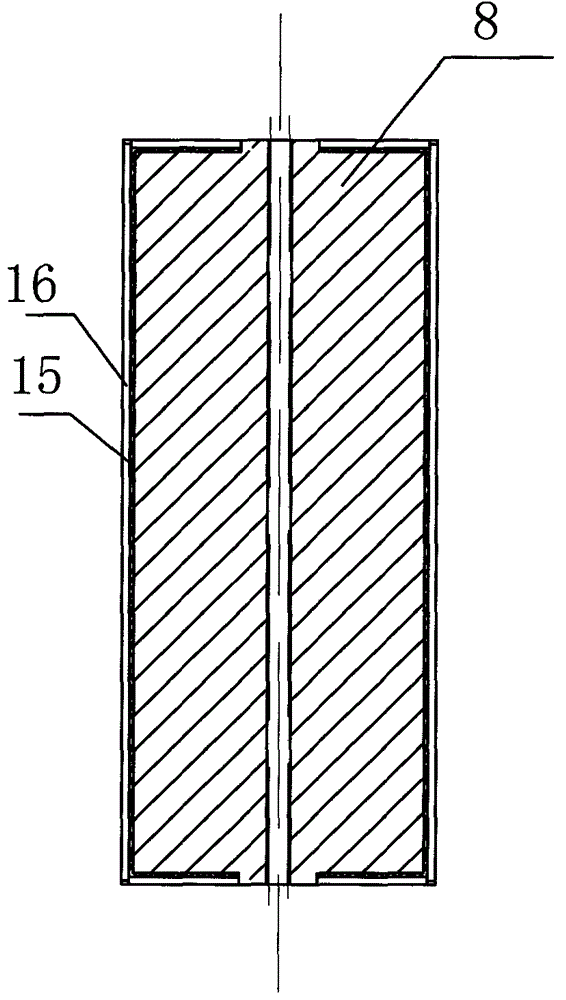

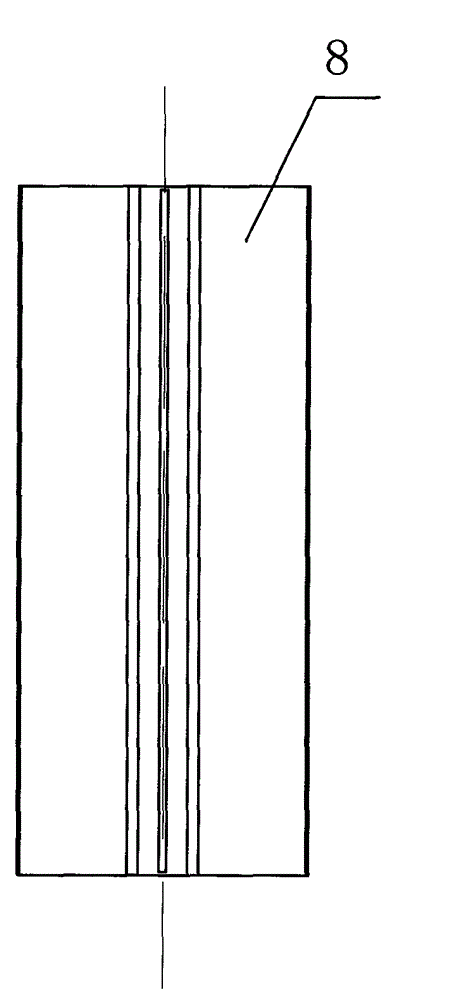

[0045] to attach figure 1 — attached Figure 16 For example:

[0046] The engine of the present invention mainly comprises: output shaft 1, connecting rod fixed disk 2 sleeved on the output shaft, rotor 8, rotating plate 6, axle sleeve 9, connecting rod 3 connecting rotating plate 6 and connecting rod fixed disk 2, control Several parts such as the guide rail 4 of connecting rod movement, the cylinder 7 that is sleeved on the rotor 8 and the rotating plate 6, the support 5 connecting the cylinder 7 and the guide rail 4.

[0047] One end of the output shaft 1 is located inside the engine, and one end is used for power output, and the part located in the engine is processed with splines; the output shaft 1 is equipped with the rotor 8, the rotating plate 6, and the connecting rod fixing plate 2. The output shaft 1, the rotor 8, and the connecting rod fixing plate 2 are splined together to form a whole and rotate together; the installation of the output shaft 1 and the rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com