Floating ball valve

A technology of floating ball valve and valve stem, which is applied in the direction of valve details, valve device, valve shell structure, etc., can solve problems such as leakage and affecting service life, so as to ensure safety and reliability, strengthen sealing, and avoid internal leakage and external leakage. Dangerous effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

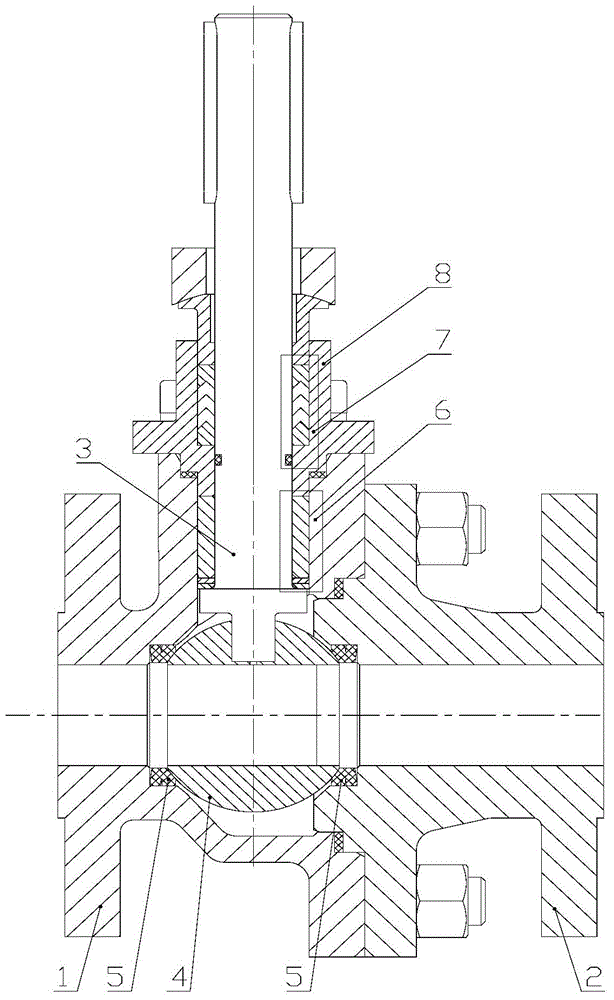

[0022] Attached below Figure 1~4 To further describe the invention in detail, the description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

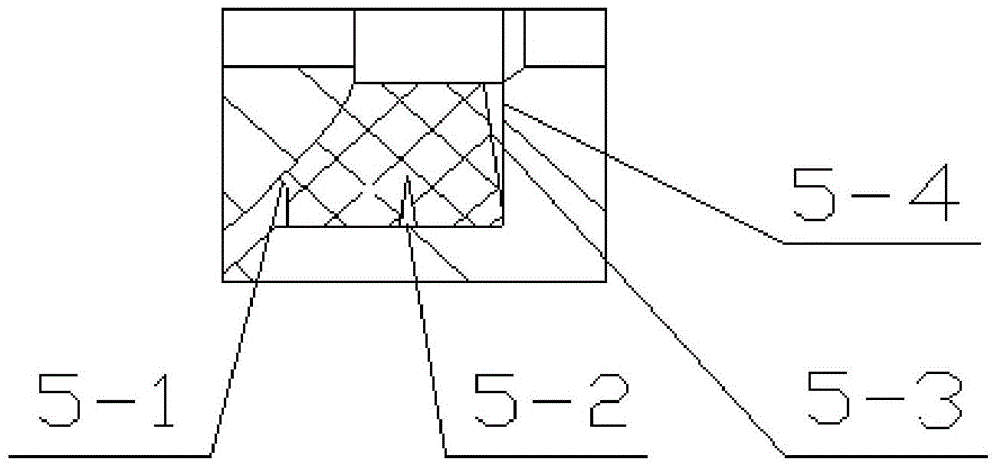

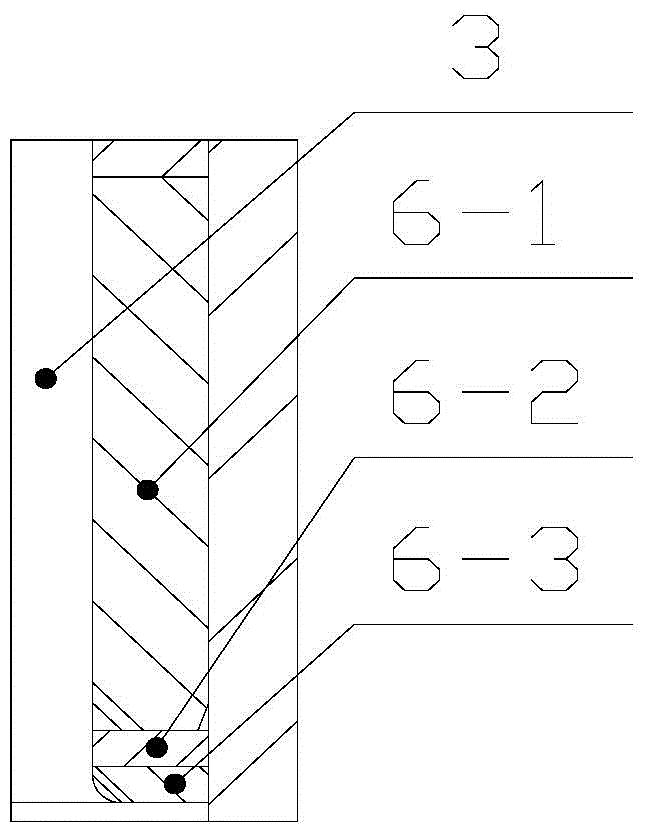

[0023] Such as figure 1 As shown, a floating ball valve proposed by the present invention includes: a valve body composed of a first valve body part 1 and a second valve body part 2, which are detachably connected; in the valve body, the ball 4 is floating, and the valve stem 3 to drive the sphere 4 to complete the switching action. When the valve is closed, the ball 4 has a certain displacement under the medium pressure and presses tightly on the valve seat 5 at the outlet end to form a spherical seal; the valve stem guide structure 6 maintains the stability of the valve stem 3, and the stuffing box 8 is equipped with The packing and the valve stem sealing structure 7 ensure the sealing performance of the valve stem 3 and prevent the medium fr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap