A heavy-duty reproducible brake detection test device for heavy-duty multi-axle vehicles

A test device and brake test technology, which is applied in the direction of measuring device, vehicle test, lifting device, etc., to achieve the effect of reasonable structure design, reducing modification process and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

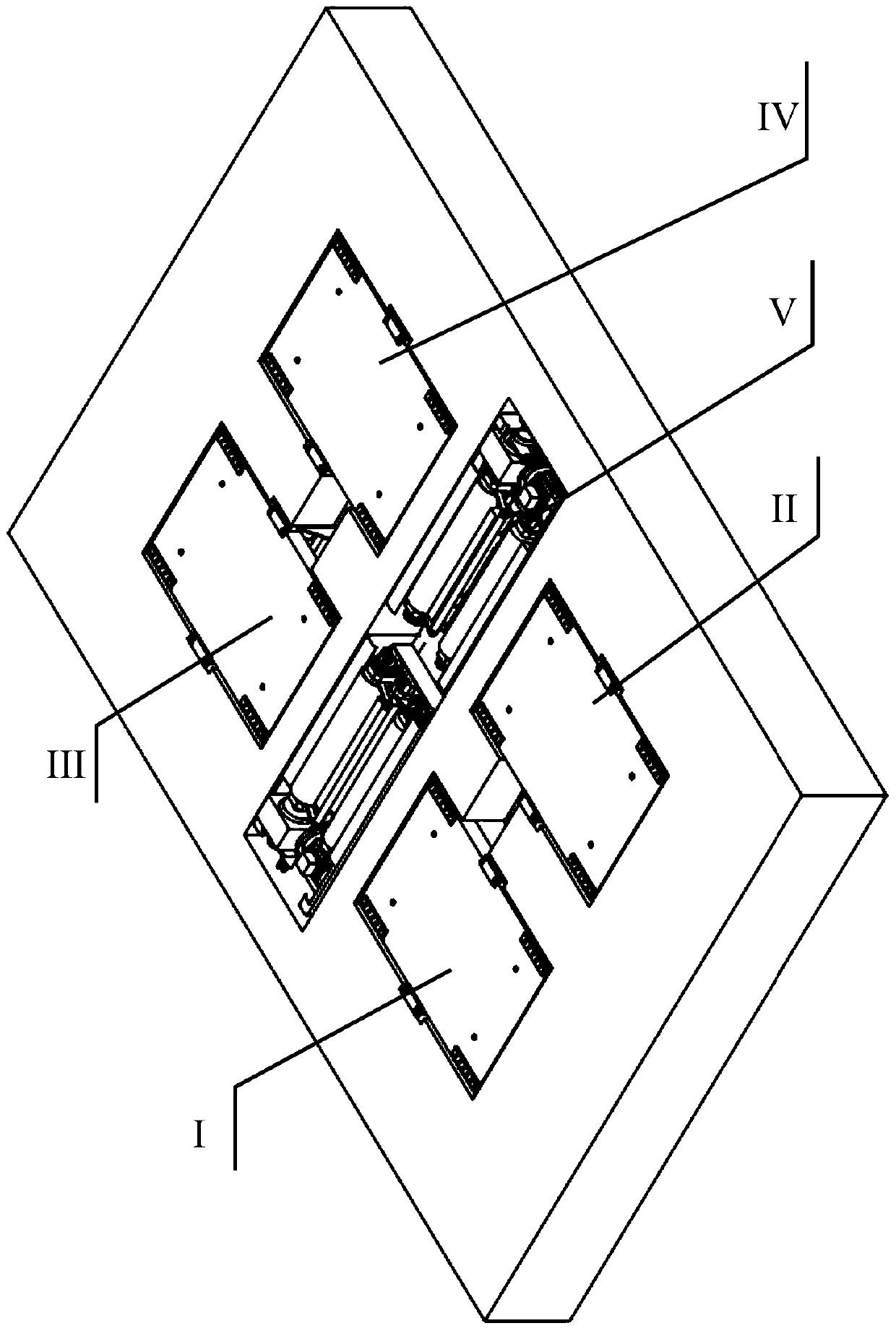

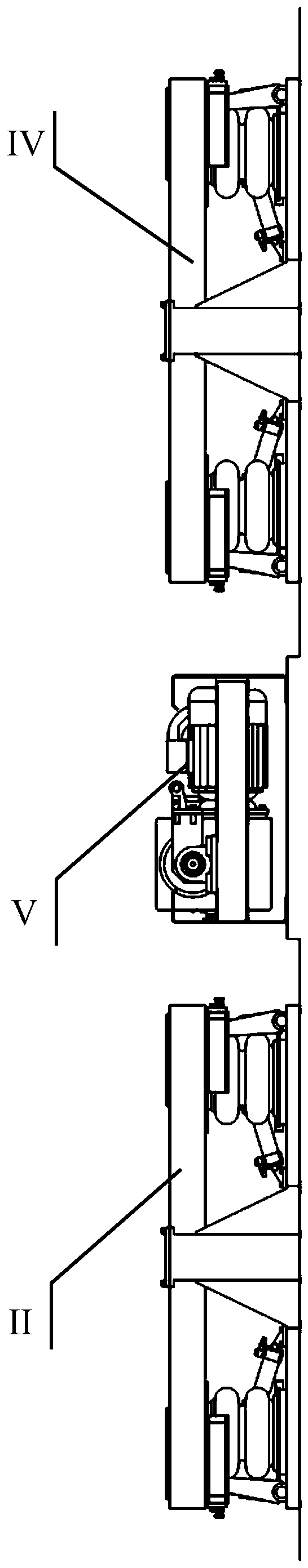

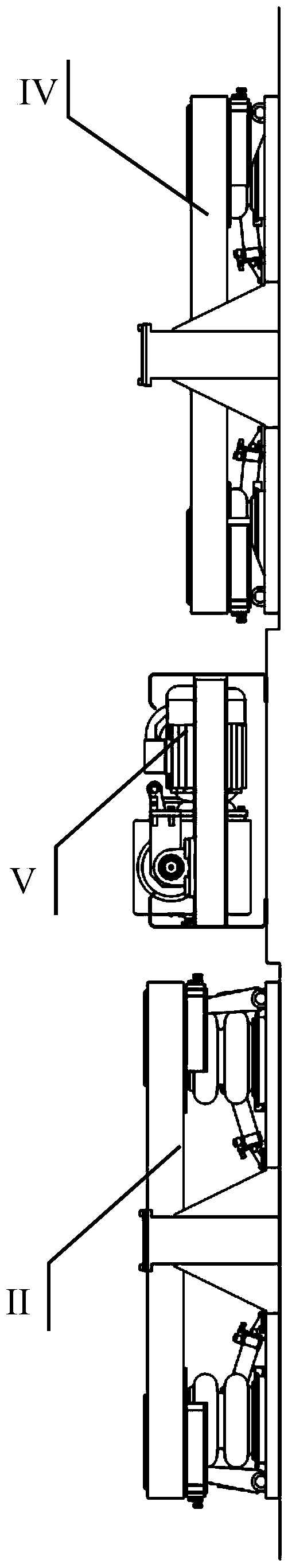

[0042] refer to figure 1 , a heavy-duty multi-axle vehicle heavy-duty reproducible brake detection test device, the device includes No. 1 lifting mechanism I, No. 2 lifting mechanism II, No. 3 lifting mechanism III and No. 4 lifting mechanism IV, wherein the No. 1 lifting mechanism I, No. 2 lifting mechanism II, No. 3 lifting mechanism III and No. 4 lifting mechanism IV have the same structure, and they are all arranged on four equal-depth horizontal foundation planes. No. 1 lifting mechanism I It is aligned with No. 2 lifting mechanism II and placed in front of the roller brake test bench V, and No. 3 lifting mechanism III and No. 4 lifting mechanism IV are placed side by side and aligned and placed behind the roller brake test bench V; The longitudinal centerlines of No. 1 Lifting Mechanism I and No. 3 Lifting Mechanism III coincide with the right side driving centerline of Roller Brake Test Bench V, and the No. 2 Lifting Mechanism II and No. 4 Lifting Mechanism IV The long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com