Transport system, in particular transverse stretching systems

A technology of conveying system and stretching equipment, which is applied in the field of conveying system to achieve the effect of reducing the longitudinal force of the chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

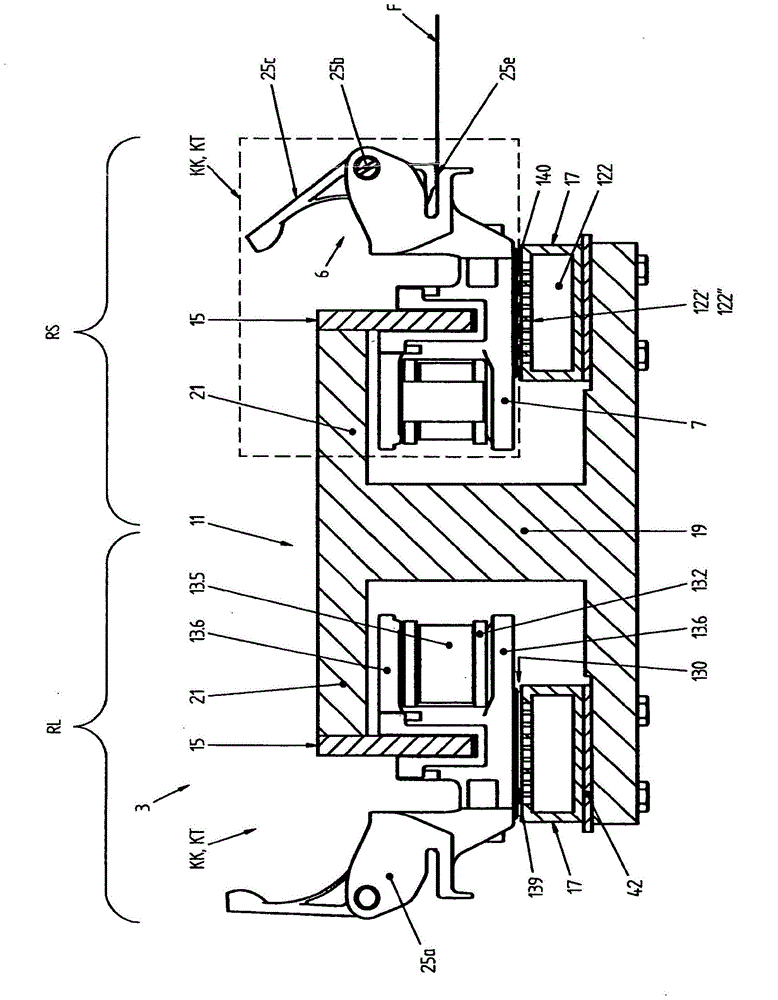

[0045] The conveying system of a stretching plant usually includes gravity slides and guide rails, however, the gravity slides and guide rails can also be combined in one track unit.

[0046] The invention is explained below with the aid of a width stretching machine, ie a transverse stretching device (for example, which can be used in a sequential stretching device).

[0047] basic structure

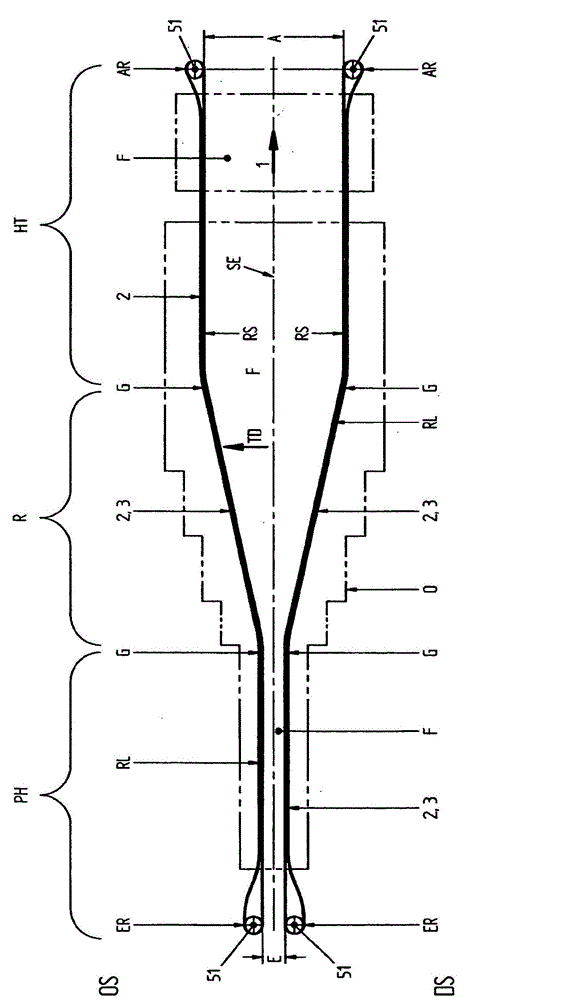

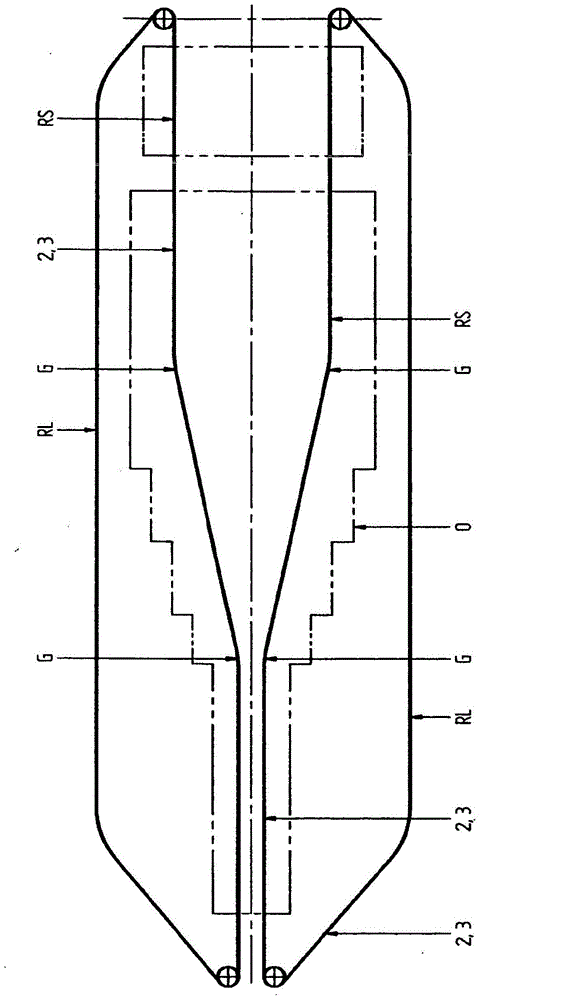

[0048] The described film width stretching device or transverse stretching device, which is also referred to below as a TD stretching device (TD=transverse direction) for short, is known to have two symmetrically configured drive systems. exist Figure 1a Two drive systems which extend perpendicular to the drawing plane and are arranged symmetrically with respect to the plane of symmetry SE are depicted, wherein between the two drive systems which run around the closed rail 2, the drive system to be processed (ie to be stretched ) of the web, in particular in the form of a plastic film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com