Preliminary leaf knocking method and device for cane harvesting machine

A harvester and pre-threshing technology, which is applied to harvesters, agricultural machinery and implements, agriculture, etc., can solve the problems of high trash content, low efficiency, and low loading tonnage, so as to reduce trash content and ingeniously set up , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

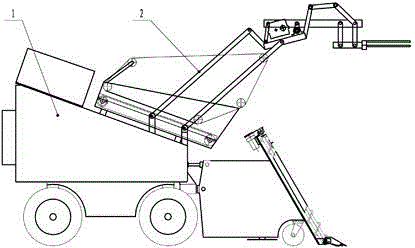

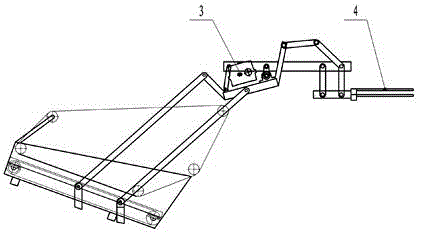

[0035] As shown in the figure, the leaf-threshing device used in the pre-threshing method of the sugarcane harvester is a pre-threshing device 2 that moves up and down, and it includes a leaf-threshing mechanism 4 and a motion mechanism 3 that can make the leaf-threshing mechanism 4 reciprocate up and down. Described beating mechanism 4 is installed in motion mechanism 3 front parts, and motion mechanism 3 rear parts are connected to the front upper part of the sugarcane harvester 1 that cane-holding device is installed by height adjustment arm bar.

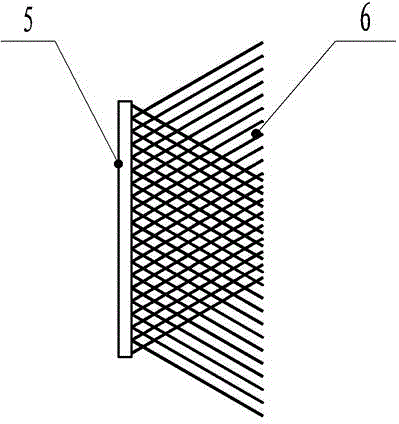

[0036] Described beating mechanism 4 comprises beating bar mounting seat 5 and beating bar 6, and beating bar 6 is installed on beating bar mounting seat 5, and the installation of beating bar 6 needs to use at least four beating bars 6 parallel Or cross and combine to form a quadrilateral with an empty hole in the middle, and the width of the empty hole is 10mm-60mm.

[0037] The beating bar 6 is made of metal or polymer materia...

Embodiment 2

[0041] The leaf-threshing device adopted in the pre-threshing method of sugarcane harvester is a rotating hub type pre-threshing device, comprising a driving rotating hub 7 and a supporting arm 9, and the driving rotating hub 7 is installed on the front portion of the supporting arm 9, and the supporting arm 9 The rear portion is installed on the front upper part of the sugarcane harvester 1 that the cane-holding device is installed, and the beating bar 6 is installed on the driving hub 7, and the driving element 8 is also installed on one side of the driving hub 7.

[0042] The drive element 8 is a hydraulic drive motor or a drive motor.

[0043] The support arm 9 is also connected with the sugarcane harvester 1 through a hydraulic cylinder.

[0044] The beating bar 6 is made of metal or polymer material.

Embodiment 3

[0046] The leaf-threshing device used in the pre-threshing method of the sugarcane harvester is a rotary pre-threshing device, including a leaf-threshing bar 6, a driving element 8 and a support arm 9, and the leaf-threshing bar 6 is installed on the support arm 9 through the driving element 8 On, support arm 9 is respectively installed on the front upper part of the sugarcane harvester 1 both sides that the cane-holding device is installed.

[0047] The drive element 8 is a hydraulic drive motor or a drive motor.

[0048] The support arm 9 is also connected with the sugarcane harvester 1 through a hydraulic cylinder.

[0049] The beating bar 6 is made of metal or polymer material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com