Ultrafine electroplating material grinding crusher

A pulverizer and grinder technology, used in chemical instruments and methods, dissolving, grain processing, etc., can solve the problems of poor sealing, low efficiency, low precision, etc., and achieve wide coverage, high control flexibility, and improved precision. effect on efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

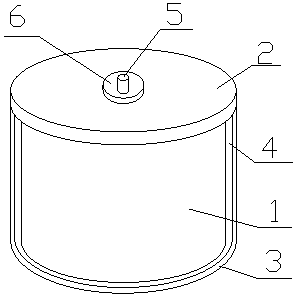

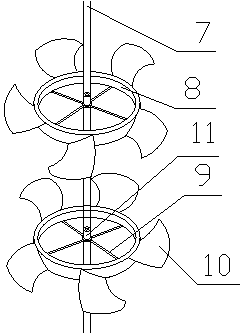

[0031] An ultra-fine electroplating material grinder, comprising a cylindrical grinder main body 1, a sealing cover 2, and a main body fixing frame 3, wherein the sealing cover 2 is provided with an annular groove matching the opening of the grinding machine main body 1, and the grinding machine main body 1. The main body fixing frame 3 is arranged on the outside, and there is a gap 4 between the outer wall of the grinding machine main body 1. The grinding machine main body 1, the sealing cover 2 and the main body fixing frame 3 can move relative to each other. The main body of the grinding machine 1 is provided with a grinding assembly inside, and a drive motor 5 and a controller are provided outside. The grinding assembly includes a wheel disc 10 and a central shaft 9. The center of the wheel disc 10 is provided with a bearing 11, and the outer ring of the wheel disc 10 At least three blades are evenly arranged; one end of the central shaft is provided with a wheel 10, and th...

specific Embodiment 2

[0034]An ultra-fine electroplating material grinder, comprising a cylindrical grinder main body 1, a sealing cover 2, and a main body fixing frame 3, wherein the sealing cover 2 is provided with an annular groove matching the opening of the grinding machine main body 1, and the grinding machine main body 1. The main body fixing frame 3 is arranged on the outside, and there is a gap 4 between the outer wall of the grinding machine main body 1. The grinding machine main body 1, the sealing cover 2 and the main body fixing frame 3 can move relative to each other. The main body of the grinding machine 1 is provided with a grinding assembly inside, and a drive motor 5 and a controller are provided outside. The grinding assembly includes a wheel disc 10 and a central shaft 9. The center of the wheel disc 10 is provided with a bearing 11, and the outer ring of the wheel disc 10 At least three blades are evenly arranged; one end of the central shaft is provided with a wheel 10, and the...

specific Embodiment 3

[0037] An ultra-fine electroplating material grinder, comprising a cylindrical grinder main body 1, a sealing cover 2, and a main body fixing frame 3, wherein the sealing cover 2 is provided with an annular groove matching the opening of the grinding machine main body 1, and the grinding machine main body 1. The main body fixing frame 3 is arranged on the outside, and there is a gap 4 between the outer wall of the grinding machine main body 1. The grinding machine main body 1, the sealing cover 2 and the main body fixing frame 3 can move relative to each other. The main body of the grinding machine 1 is provided with a grinding assembly inside, and a drive motor 5 and a controller are provided outside. The grinding assembly includes a wheel disc 10 and a central shaft 9. The center of the wheel disc 10 is provided with a bearing 11, and the outer ring of the wheel disc 10 At least three blades are evenly arranged; one end of the central shaft is provided with a wheel 10, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com