Combined drive bionic elbow joint

A bionic elbow and compound power technology, applied in manipulators, manufacturing tools, joints, etc., can solve the problems of low motor power, occupy a lot of space, limit the development of joints, etc., and achieve the effect of increasing driving power and saving space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

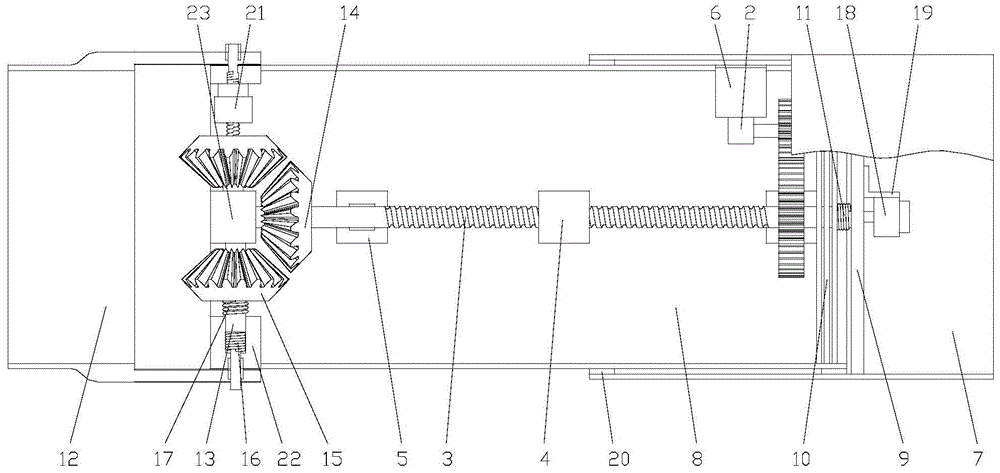

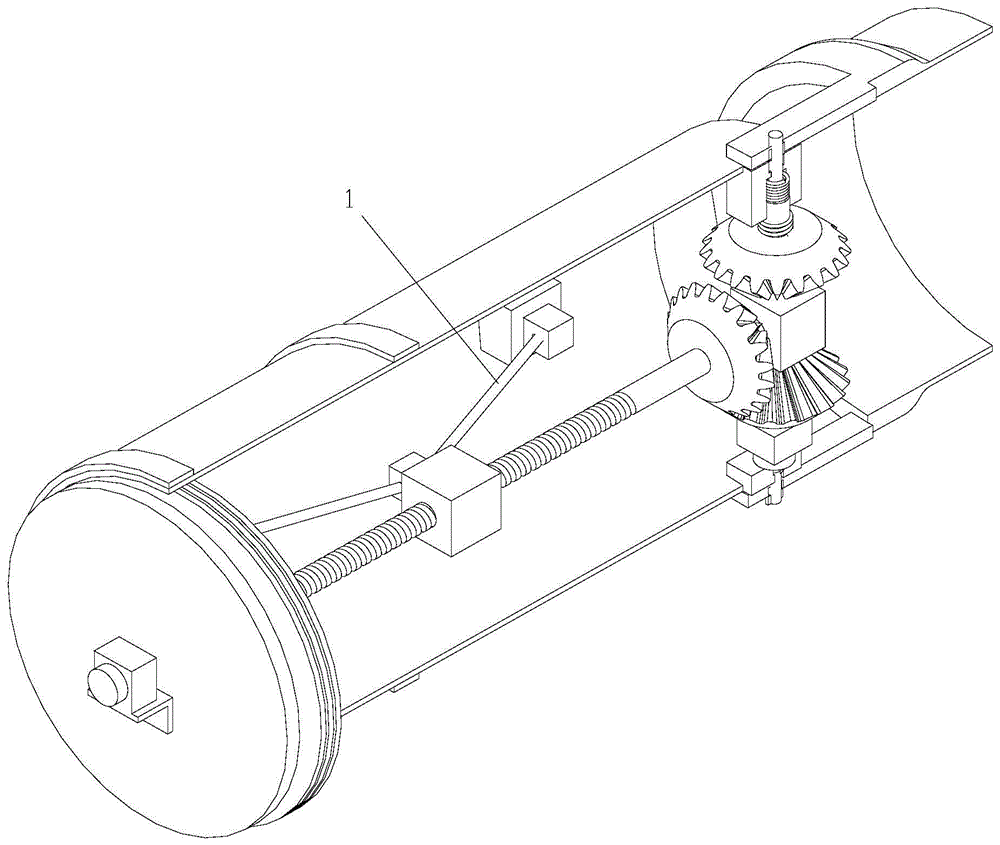

[0015] figure 1 It is the front view of the present invention; figure 2 It is an isometric view of the present invention, as shown in the figure: the compound-driven bionic elbow joint of this embodiment includes a compound power source, a joint housing and a driving part for driving joint movement; the compound power source includes a memory alloy Wire 1 and motor 2; the driving part includes a screw 3 and a slider 4, the screw 3 is driven to rotate by the motor 2, and the memory alloy wire 1 is connected between the slider 4 and the joint housing for along the The screw 3 axially provides force for the slider 4; the slider 4 is connected with the screw 3 to form a screw nut pair, and in the simulation of the rotation and extension and flexion of the elbow joint, the force generated by the phase transition of the memory alloy is used to offset the joint. Most of the force required for movement, while utilizing the self-locking characteristics of the lead screw 3, the joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com