Hand cutting prevention security device of full-open hydraulic paper cutter

A paper cutter and hydraulic technology, which is applied in the field of anti-cutting safety devices for full-open hydraulic paper cutters, can solve problems such as the indicator light not being on, the shutdown waiting for repair, and weak signals, so as to improve the safety protection factor, improve work efficiency, The effect of reducing downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

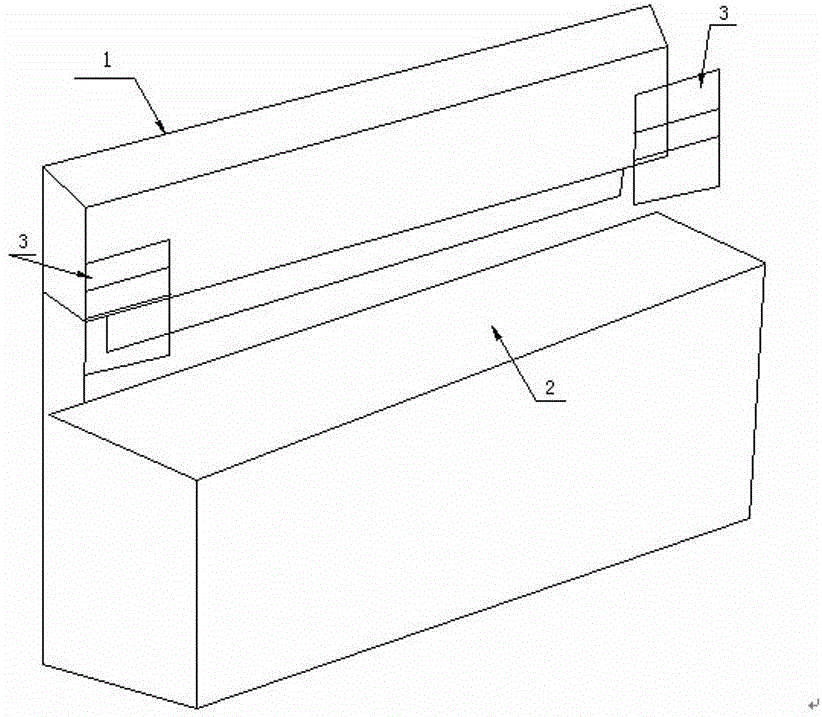

[0010] The present invention as figure 1 shown.

[0011] The full-open hydraulic paper cutter anti-hand safety device includes a full-open hydraulic paper cutter 1 and a working platform 2, and a grating signal transmission device 3 is installed on both sides of the full-open hydraulic paper cutter 1 above the working platform 2.

[0012] The grating signal transmission device 3 is an LDKS-Ⅲ photoelectric protector.

[0013] The working principle of LDKS-Ⅲ type photoelectric protector is that the emitter on the left side of the machine emits 4 beams of infrared beams with a thicker diameter, which are reflected to the left by the reflector on the right, and then the emitter on the left receives each beam of infrared beams by itself. Form a row of 8-beam infrared light curtains, and the arm can block one of the beams at will, which can disconnect the signal for protection. The advantages of this system compared with the original device are: the diameter of each beam of indepe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com