Stereo lithography rapid moulding scanning-path ordering method for 3D printing

A technology of stereo light curing and scanning path, applied in the field of 3D printing, can solve the problem of low scanning efficiency, and achieve the effect of high integration, improved molding strength, and efficient sorting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

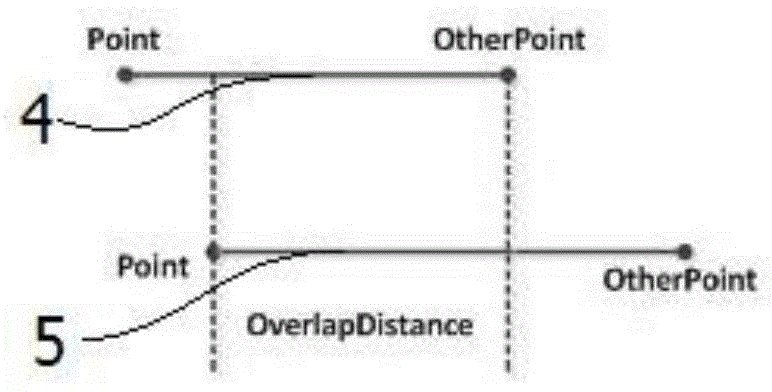

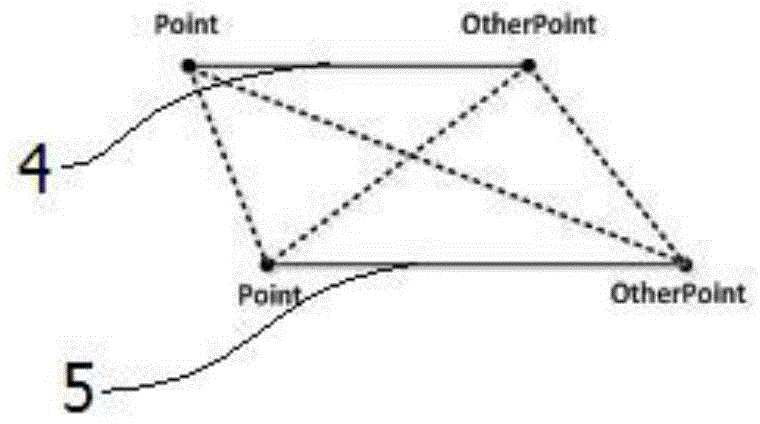

[0062] Such as Figure 4 The illustrated embodiment is a scanning path sorting method for stereolithography rapid prototyping of 3D printing, comprising the following steps:

[0063] Step 100, establish a two-dimensional array of each scan line segment according to the obtained scan line segment:

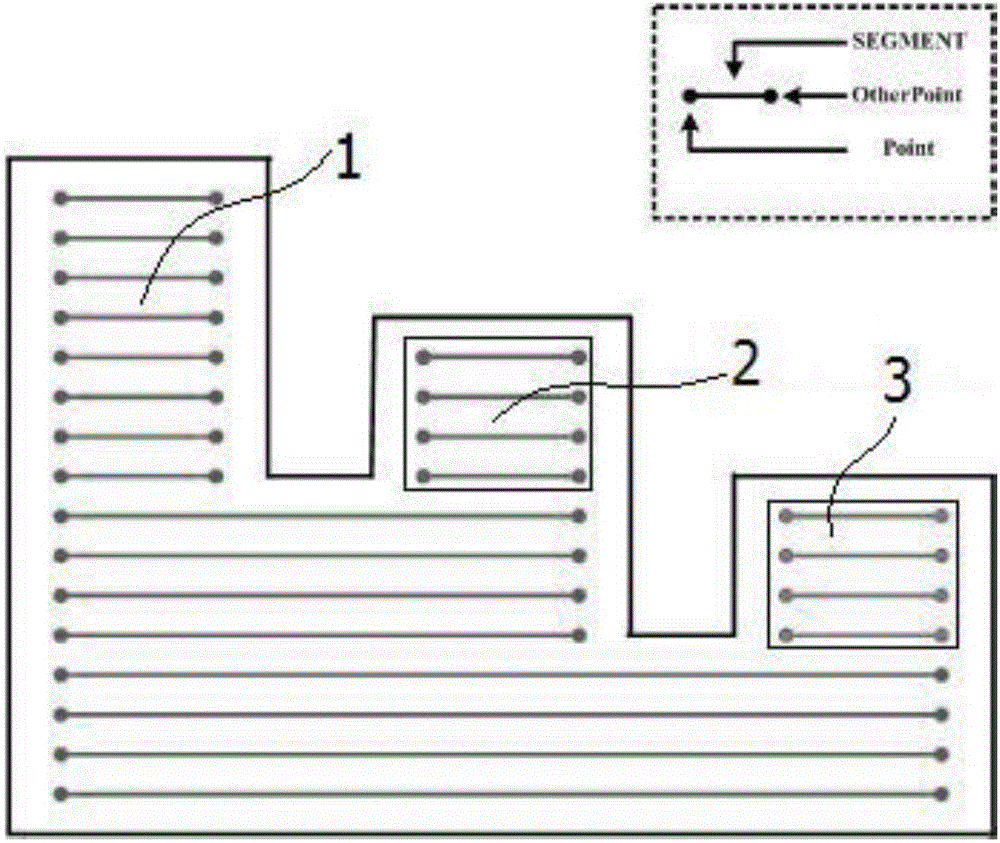

[0064] Input the contour of the object into the computer in advance, and use horizontal grid cutting to obtain such as figure 1 For all the scanning line segments arranged in sequence along the vertical direction, the following calculation process is carried out in the computer:

[0065] Set the data structure of each scan line segment as SEGMENT, and SEGMENT includes the attribute Point representing the left end point of the scan line segment, the attribute OtherPoint representing the right end point of the scan line segment, and the attribute BIn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com