Automatic sheet material feeding apparatus and feeding method preventing absorbing multi-layered sheet material

An automatic feeding and sheet technology, which is applied in the direction of thin material handling, transportation and packaging, and object separation, can solve the problems of difficult separation, enhanced adsorption force, and inability to separate sheets, so as to improve reliability and safety and achieve good results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

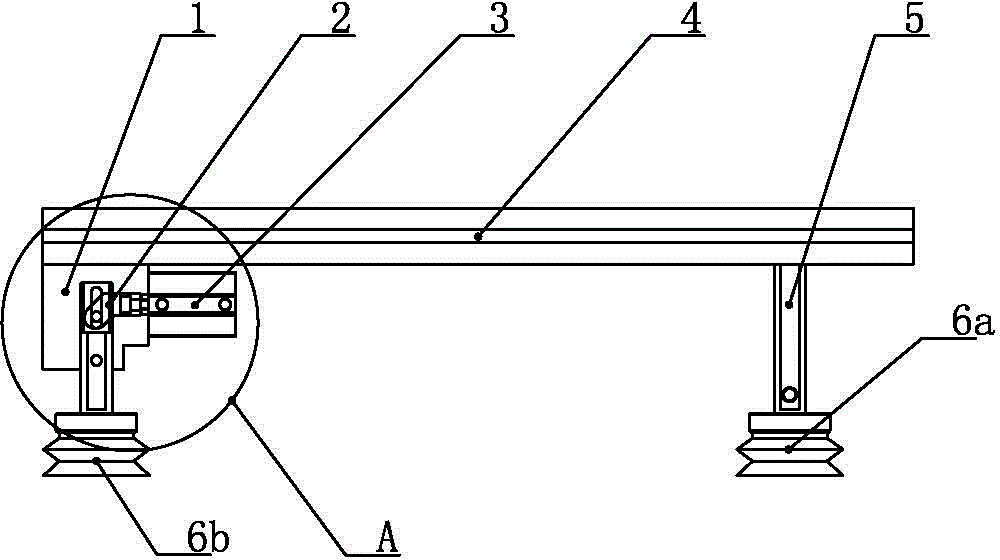

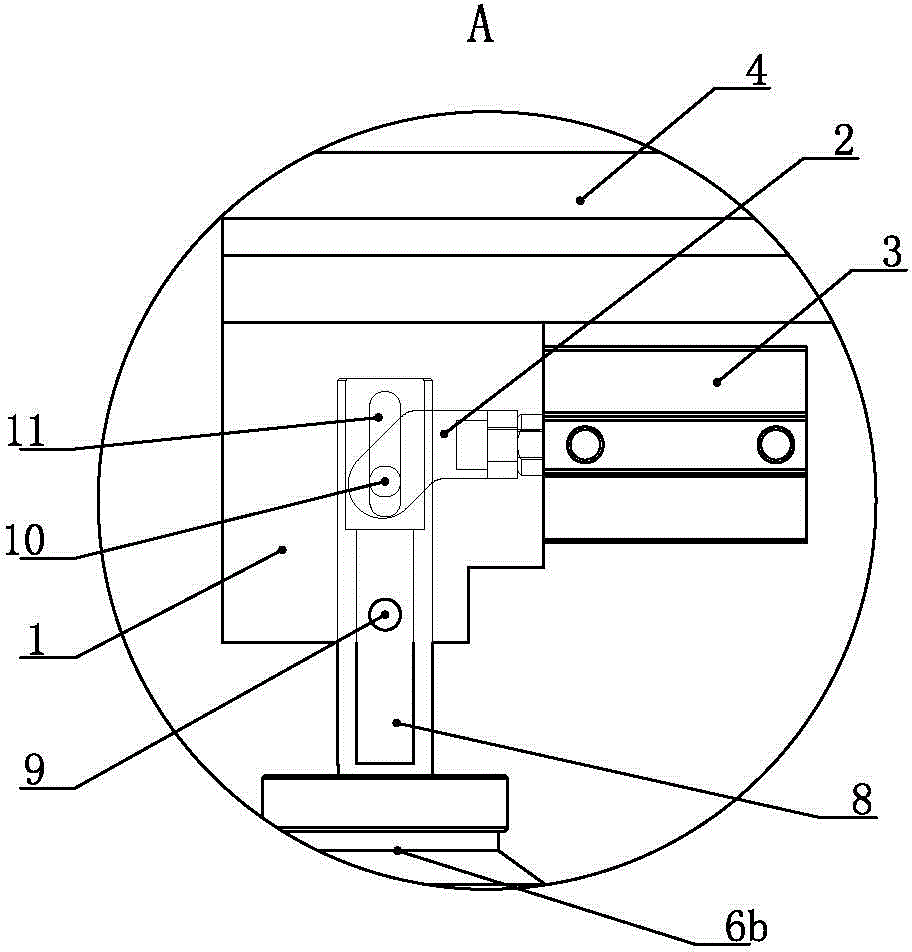

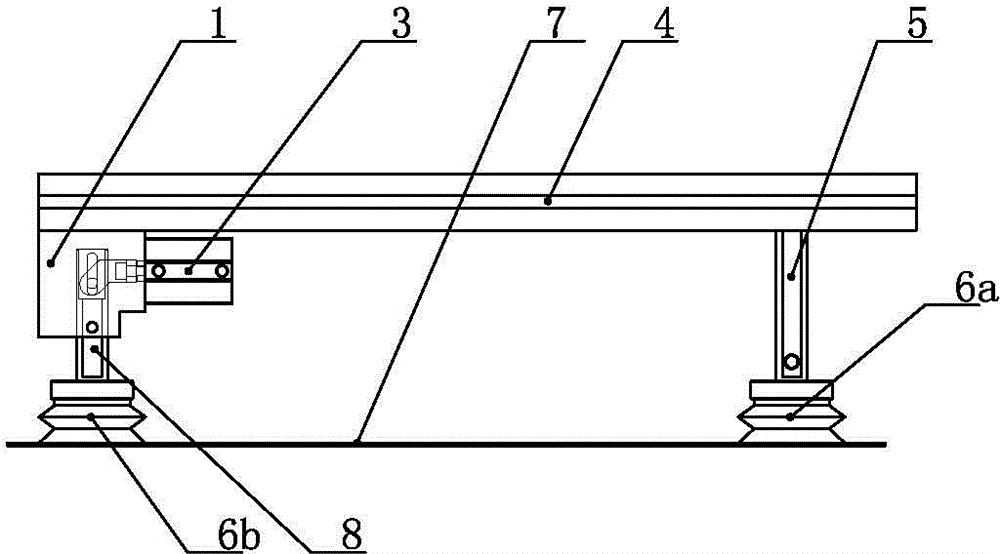

[0027] Such as Figure 1-5 As shown, it is a plate automatic feeding device for preventing multi-layer plates from being picked up. It includes a suction cup bracket 4, and a number of suction cups are installed in an array under the suction cup bracket 4. The suction cups include a fixed suction cup 6a and a movable suction cup 6b. 5 is connected to the lower side of the suction cup bracket 4; the movable suction cup 6b is correspondingly provided with one at a corner of the plate 7, the movable suction cup 6b is connected to the lower end of the swing rod 8, and the lower side of the suction cup bracket 4 is correspondingly provided with a connecting block 1 with the swing rod 8, and connected A cylinder 3 is arranged on the side of the block 1, the piston rod extension end of the cylinder 3 is connected with a cylinder joint 2, the middle part of the swing rod 8 is hinged with the connecting block 1 through the lower pin 9, the upper part of the swing rod 8 is provided with ...

Embodiment 2

[0035] Such as Figure 6 As shown, it is another automatic plate feeding device that prevents the multi-layer plate from being picked up. The difference between it and Embodiment 1 is that the movable suction cup 6b is provided with two or more along one side of the plate, and the corresponding cylinder The axis of 3 is set horizontally, and the 3 axes of adjacent cylinders are set at an angle of 2~5°. Figure 6 Among them, the included angles between cylinder axes M1 and M2, M2 and M3, M3 and M4, M4 and M5 are 2~5°.

[0036] When the suction cup grabs the plate 7, due to the inconsistent swing of the adjacent swing rods 8, not only the plate itself is bent and deformed during the bending process of the plate 7, but also the adjacent swing rod 8 also drives the plate 7 to be partially twisted, and the axis of the adjacent cylinder 3 is in the shape of The angle setting is 2~5°, so that such distortion can obviously promote the delamination of the plate.

Embodiment 3

[0038] Such as Figure 7 As shown, it is the third type of sheet material automatic feeding device that prevents multi-layer sheet materials from being picked up. It is different from Embodiment 1 in that the movable suction cup 6b is arranged at the diagonal. The boards 7 can be layered from two opposite corners. As long as the upper and lower boards 7 are separated at any corner, the boards can be layered smoothly and the boards can be prevented from sticking together by adsorption.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com