Oil stain detergent and preparation method thereof

A kind of oil stain cleaning agent and back-up technology, applied in the field of kitchen cleaning, can solve problems such as difficult to remove, user discomfort, and high flour cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

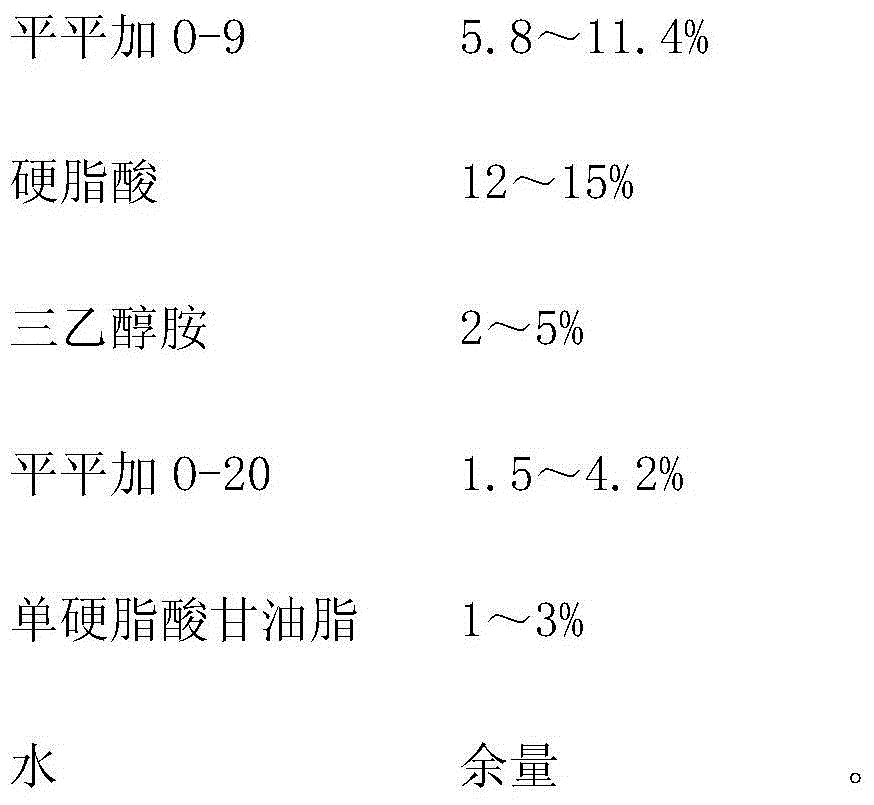

preparation example Construction

[0033] The preparation method of above-mentioned greasy dirt cleaning agent comprises the following steps:

[0034] (1) Weigh each component according to the measurement, and set aside;

[0035] ⑵ Add Pingpingjia O-20 into the heated pure water, stir well and set aside;

[0036] (3) Add stearic acid into heated pure water, stir until translucent liquid and set aside;

[0037] (4) Add glycerol monostearate into heated pure water, stir until translucent liquid and set aside;

[0038] (5) Add the products of step (2), step (3) and step (4) into the constant temperature reactor in order, add the remaining pure water, and stir;

[0039] ⑹Add Pingpingjia O-9 into the reaction kettle in step ⑸, continue to add triethanolamine after stirring, keep it for a period of time, and then cool down to obtain the finished product.

[0040] Wherein, the pure water in step (2) is heated to 70-80 degrees Celsius and stirred for 40 minutes. The pure water in step (3) is heated to 50-60 degrees...

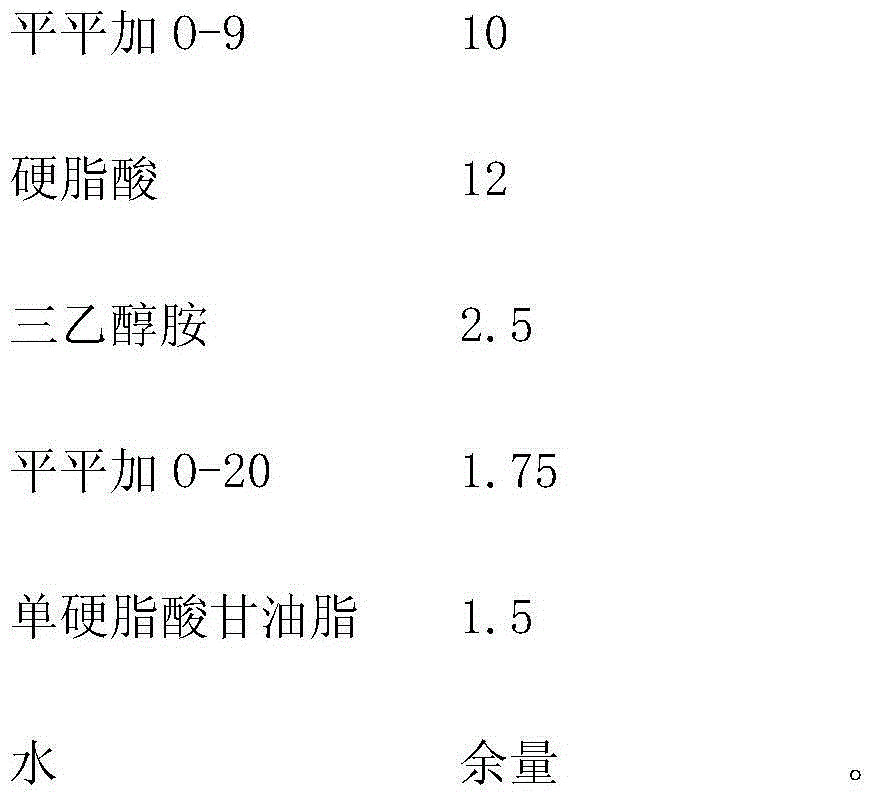

Embodiment 1

[0043]

[0044] (1) Weigh each component according to the measurement, and set aside;

[0045] (2) Add Pingpingjia O-20 into pure water at 70 degrees Celsius (one-third of the total water weight), stir for 40 minutes and set aside;

[0046] (3) Add stearic acid into pure water at 50 degrees Celsius (one-fifth of the total water weight), stir until translucent liquid and set aside;

[0047] (4) Add glyceryl monostearate into pure water (1 / 6 of the total water weight) at 80 degrees Celsius, stir until translucent liquid and set aside;

[0048] (5) Add the products of step (2), step (3) and step (4) into the constant temperature reactor in order, keep a constant temperature of 70 degrees Celsius in the reactor, stir for 30 minutes, add the remaining pure water, and stir evenly;

[0049] ⑹ Continue to add Pingpingjia O-9 into the reaction kettle of step ⑸, continue to add triethanolamine after stirring, keep stirring for 1 hour, and then naturally cool down to room temperature...

Embodiment 2

[0052]

[0053] (1) Weigh each component according to the measurement, and set aside;

[0054] ⑵ Add Pingpingjia O-20 into pure water at 80 degrees Celsius (one-third of the total water weight), stir for 40 minutes and set aside;

[0055] (3) Add stearic acid into pure water at 60 degrees Celsius (one-fifth of the total water weight), stir until translucent liquid and set aside;

[0056] (4) Add glyceryl monostearate into pure water (1 / 6 of the total water weight) at 90 degrees Celsius, stir until translucent liquid and set aside;

[0057] (5) Add the products of step (2), step (3) and step (4) into the constant temperature reactor in order, keep a constant temperature of 70 degrees Celsius in the reactor, stir for 30 minutes, add the remaining pure water, and stir evenly;

[0058] ⑹ Continue to add Pingpingjia O-9 to the reaction kettle in step ⑸, continue to add triethanolamine after stirring, keep stirring for 3 hours, and then naturally cool down to room temperature to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com