Processing method for color-deepening and brightening of pigment printed textiles

A processing method and paint printing technology, which is applied in the textile field to achieve the effect of reducing consumption, meeting the requirements of bright color and fastness, and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A processing method for increasing the depth and color of pigment-printed textiles, the process flow: preparation of color paste→printing→drying→baking→post-treatment,

[0027] Specific process prescription:

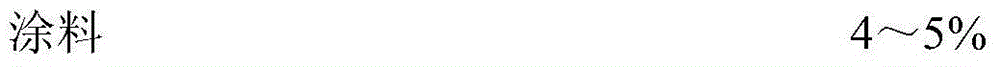

[0028] Each component of color paste by weight percentage is:

[0029]

[0030] The paint described is: paint peach red D-118; the adhesive is: Haili Chailin VT ECO; the thickener is: BASF HIT; the darkening and brightening agent is: darkening and brightening agent A; the color fixing agent is : Fixing agent FK200.

[0031] The present invention according to above-mentioned process prescription, concrete operations are as follows:

[0032] (1) Preparation of color paste: first add thickener to half of the water and stir thoroughly to make it completely dissolved, then add adhesive, paint, and darkening and brightening agent in turn and stir to obtain mixed liquid a, then add solid to the other half of the water The colorant is completely dissolved to obtain ...

Embodiment 2

[0038] A processing method for increasing the depth and color of pigment-printed textiles, the process flow: preparation of color paste→printing→drying→baking→post-treatment,

[0039] Specific process prescription:

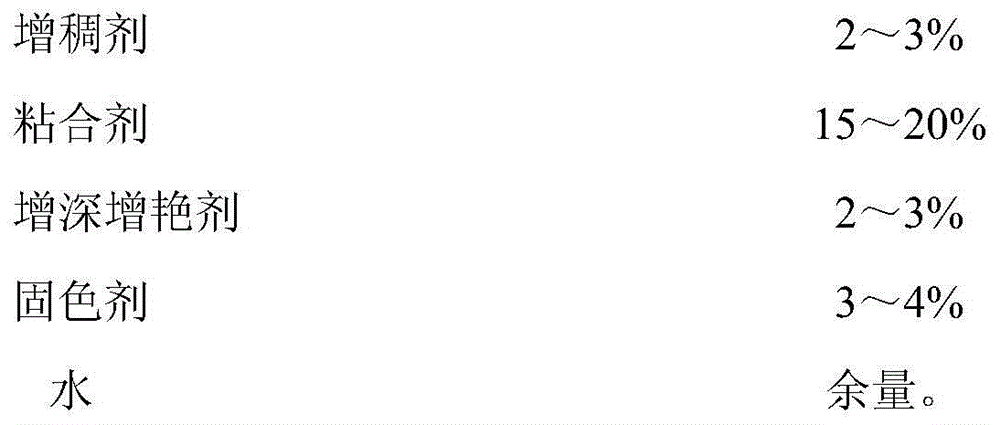

[0040] Each component of color paste by weight percentage is:

[0041]

[0042] The paint described is: paint blue D-301; the adhesive is: Haili Chailin VT ECO; the thickener is: BASF HIT; the darkening and brightening agent: darkening and brightening agent A; the color fixing agent is: Fixing agent FK200.

[0043] The present invention according to above-mentioned process prescription, concrete operations are as follows:

[0044] (1) Preparation of color paste: first add thickener to half of the water and stir thoroughly to make it completely dissolved, then add adhesive, paint, and darkening and brightening agent in turn and stir to obtain mixed liquid a, then add solid to the other half of the water The colorant is completely dissolved to obtain the mixed...

Embodiment 3

[0050] A processing method for increasing the depth and color of pigment-printed textiles, the process flow: preparation of color paste→printing→drying→baking→post-treatment,

[0051] Specific process prescription:

[0052] Each component of color paste by weight percentage is:

[0053]

[0054] The paint is: paint yellow KRC; the adhesive is: Haili Chailin VT ECO; the thickener is: BASF HIT; the darkening and brightening agent: darkening and brightening agent A; agent FK200.

[0055] The present invention according to above-mentioned process prescription, concrete operations are as follows:

[0056] (1) Preparation of color paste: first add thickener to half of the water and stir thoroughly to make it completely dissolved, then add adhesive, paint, and darkening and brightening agent in turn and stir to obtain mixed liquid a, then add solid to the other half of the water The colorant is completely dissolved to obtain the mixed solution b, and finally the mixed solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com