Facing multi-flange water-stop belt

A waterstop and veneer-type technology, which is applied in water conservancy projects, sea area projects, construction, etc., can solve the problems of weakening the strength of reinforced concrete structures, interfering with the design and construction of reinforced concrete structures, and achieves convenience in design and construction and guarantees strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

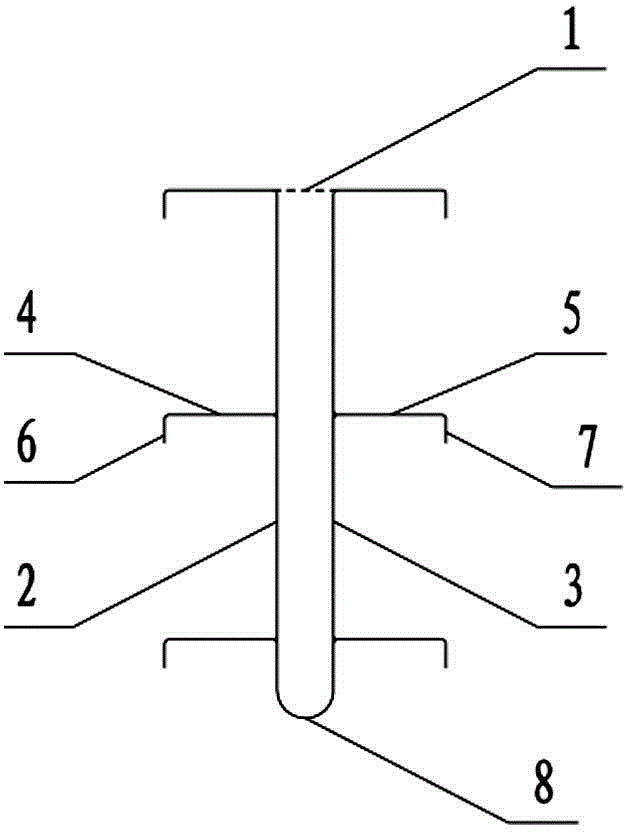

[0012] Such as figure 1 As shown, the veneer-type multi-flange waterstop of the present invention includes a waterstop body made of rubber material, the section shape of the waterstop body is a U-shaped structure, and the waterstop body is located The U-shaped opening of the body is provided with a rubber connecting diaphragm 1; the left veneer 2 and the right veneer 3 of the waterstop body are respectively provided with a left wing plate 4 and a right wing extending horizontally to both sides along the longitudinal direction of the waterstop body. Plate 5, the left and right wing plates 4, 5 are three layers arranged at intervals up and down respectively, and the outer edges of each layer of left and right wing plates 4, 5 are respectively downward vertically bent flanging structures 6, 7. The radius of the semicircular connecting section 8 at the lower end of the U-shaped waterstop body is adjusted according to the width of the concrete structure joint; the width of each lef...

Embodiment 2

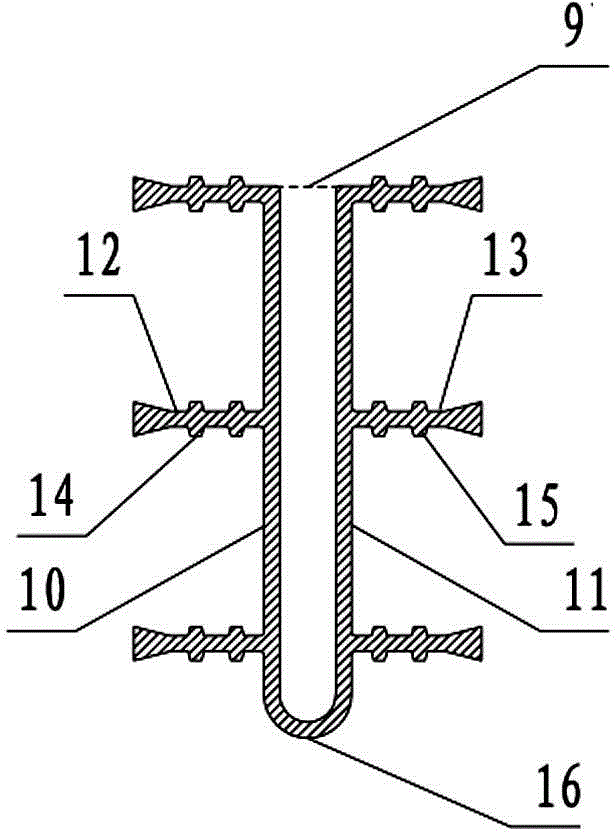

[0014] Such as figure 2 As shown, the veneer-type multi-flange waterstop of the present invention includes a waterstop body made of copper material, and the cross-sectional shape of the waterstop body is a U-shaped structure, located at The U-shaped opening of the waterstop body is provided with a copper connection diaphragm 9; the left veneer 10 and the right veneer 11 of the waterstop body are respectively provided with horizontally extending to both sides along the longitudinal direction of the waterstop body. Left wing plate 12 and right wing plate 13, said left and right wing plates 12, 13 are three layers arranged at intervals up and down respectively, and the upper and lower plates of each layer of left and right wing plates 12, 13 are spaced vertically along the waterstop body Ribs 14, 15 are provided. The radius of the semicircular connecting section 16 at the lower end of the U-shaped waterstop body is adjusted according to the width of the concrete structure joint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com