Single thick coal seam ground mining well extraction process

A technology for thick coal seam and ground, applied in the fields of fluid extraction, earth-moving drilling, wellbore/well components, etc., can solve wellbore structure damage, wellbore structure easily damaged by coal mining rock migration, difficult coalbed methane scale and high efficiency and other issues to achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

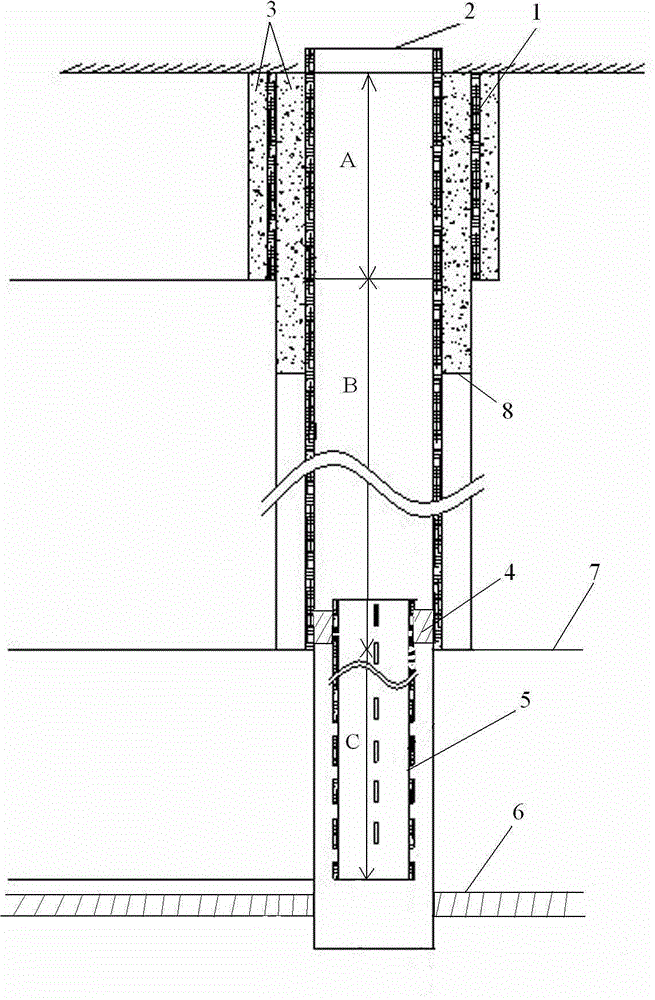

[0028] During the mining process of a single coal seam, because the well body structure is prone to complete destruction at the interface between the weathered zone and the bedrock, the present invention adopts the following methods in the three-cut drilling process: figure 1 The local cementing method shown in the figure, and the hanger device is added, and the specific process steps are as follows:

[0029] 1. Hole opening A: use φ444.5mm drill bit to open the hole, lower the φ377.7mm casing 1 for local cementing, and return the cement to the surface. Casing damage caused by formation movement can be alleviated by local cementing.

[0030] Second opening B: use φ311.1mm drill bit for conventional mud drilling, drill to the goaf coal seam floor 8 at 60m, run into φ244.5mm secondary casing 2 and secondary casing 2 after the whole well is unobstructed Install the hanger 4 at the bottom, cement and seal the bottom opening of the second open casing 2, and Hou Ning. Among them, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com