Method and device for intelligent mobile monitoring and automatic maintenance of drilling rig electric control system

An electronic control system and mobile monitoring technology, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc., can solve the problems of reduced production efficiency, reduced safety and reliability, and the cost of finding fault points and troubleshooting Long time and other problems, to achieve the effect of reducing labor intensity, ensuring high-efficiency output, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0025] The intelligent mobile monitoring and automatic maintenance method of the drilling rig electric control system according to the present invention comprises the following steps:

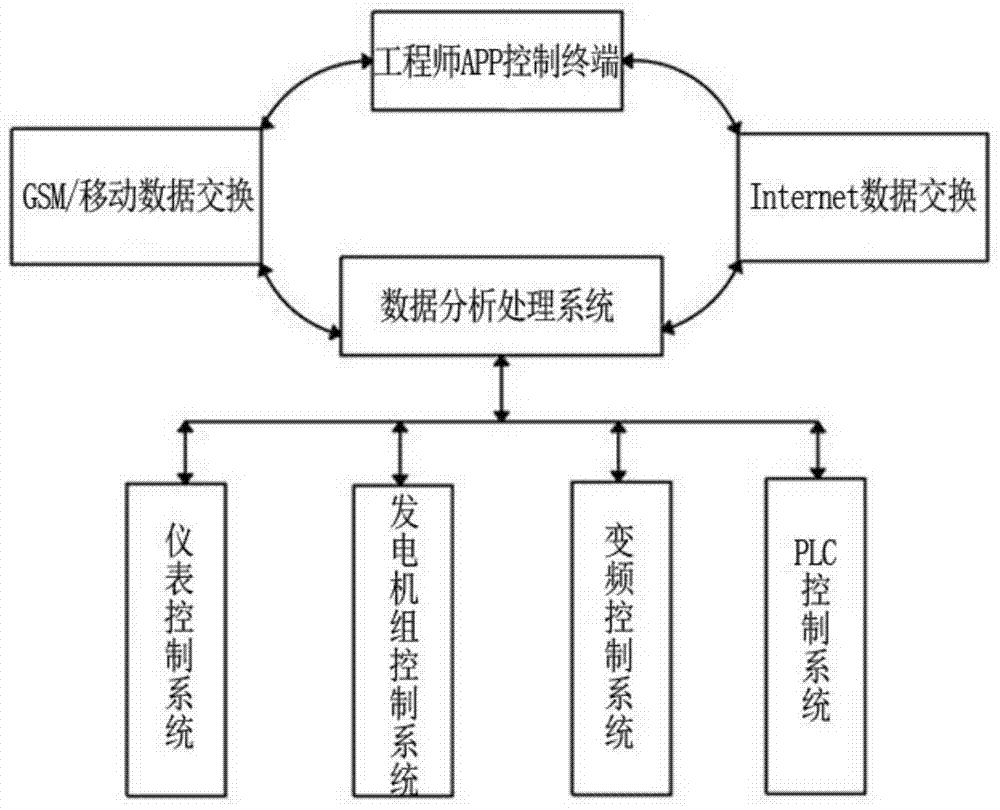

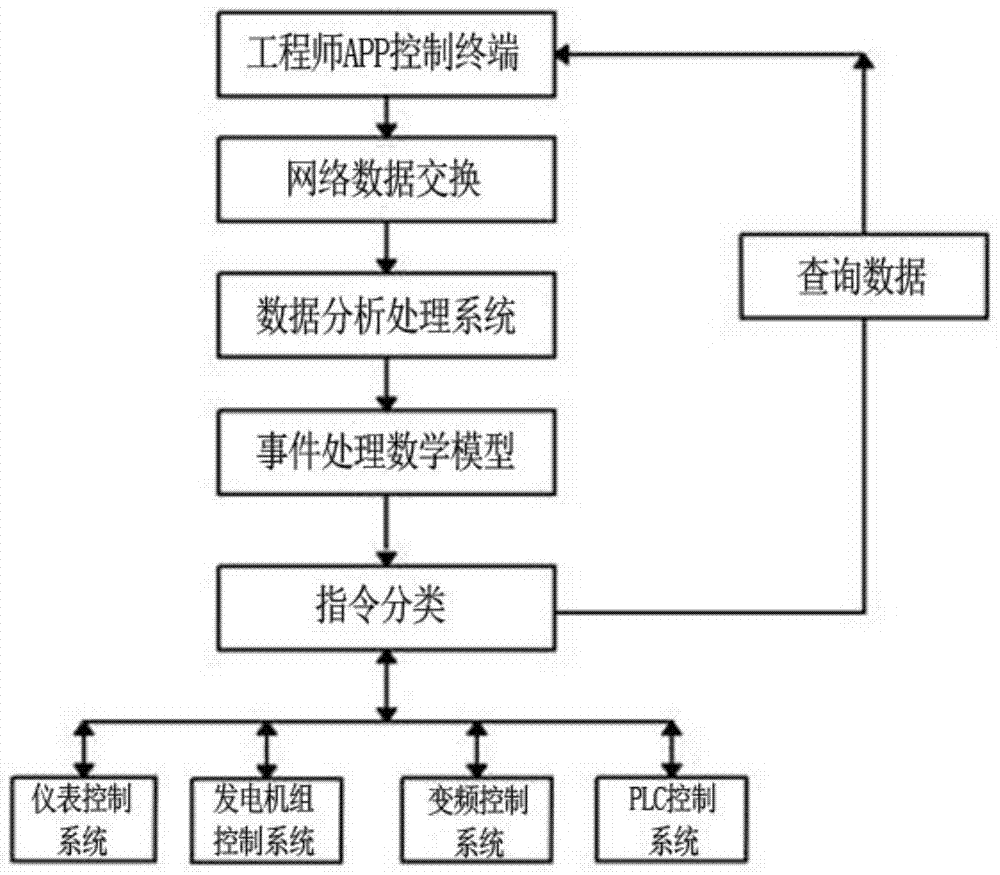

[0026] 1) The data analysis and processing system reads the data of the main control module in the instrument control system, generator set control system, frequency conversion control system and PLC control system in real time, compares it with the set data, and transmits the results to the engineer APP control terminal through the network; The engineer APP controls the terminal to receive information through the network or offline SMS;

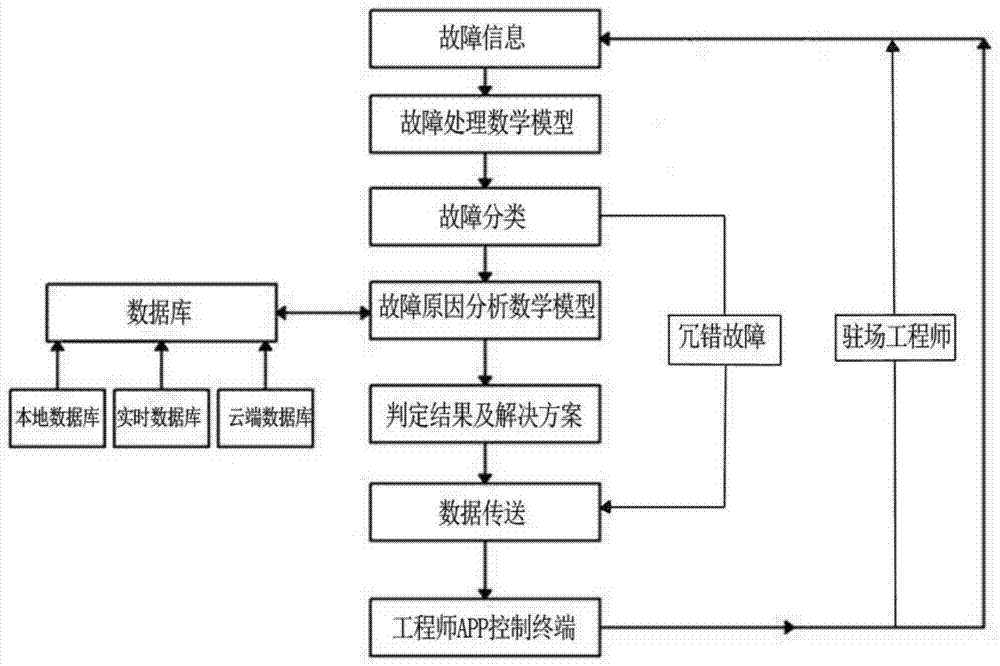

[0027] 2) When the electronic control system fails, the data analysis and processing system analyzes through the fault handling mathematical model, first determines the fault type, and if it is a redundant fault, sends a prompt m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com