Construction method of reserved grouting pipe of tunnel vault

A construction method and technology of grouting pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0018] a. After the excavation, initial support, inverted arch and bottom laying of the tunnel are completed, waterproof cloth shall be constructed on the initial support surface of the tunnel, and the second lining steel bars shall be bound;

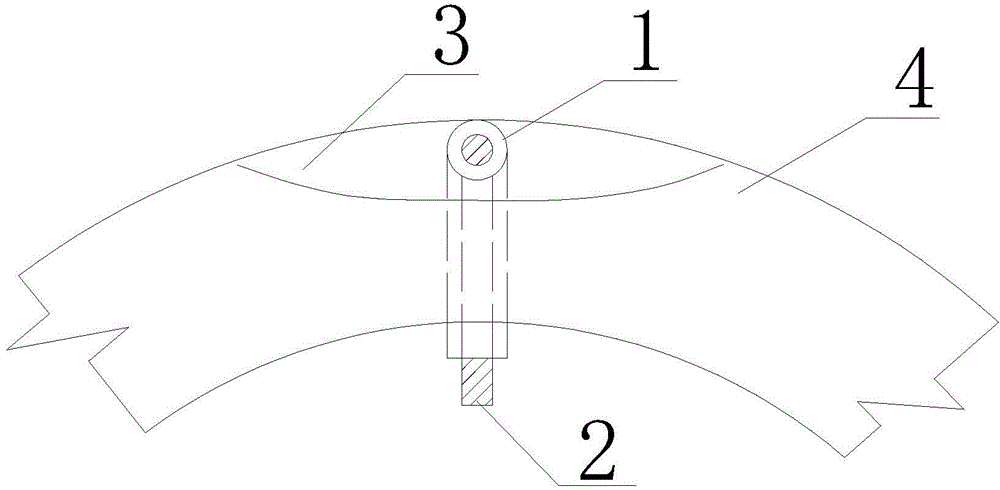

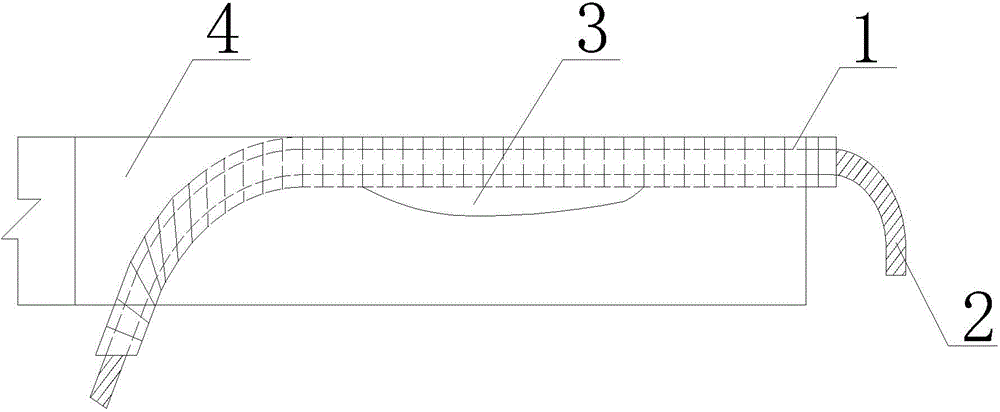

[0019] b. Before the secondary lining trolley is in place, install the perforated corrugated pipe (1) close to the waterproof cloth. The diameter of the perforated corrugated pipe (1) is 55mm, and the rubber rod (1) is inserted into the perforated corrugated pipe (1). 2), the diameter of the rubber rod (2) is 50mm, each end of the rubber rod (2) protrudes 500mm from the port of the perforated corrugated pipe (1), and the perforated corrugated pipe (1) is drawn out and fixed at both ends of the second lining trolley On the second lining steel bar, as close as possible to the waterproof board;

[0020] c. Pouring the second lining concrete (4), when pouring to the top, pull the rubber rods (2) at both ends regularly so that the grout does...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com