Test system for testing comprehensive performance of eddy current retarder and test method thereof

A technology of eddy current retarder and testing system, which is applied in the testing of machine/structural components, vehicle testing, measuring devices, etc. It can solve the problems of long cycle, complicated testing, high cost, etc., and achieve perfect functions and wide testing range , The effect of complete data collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

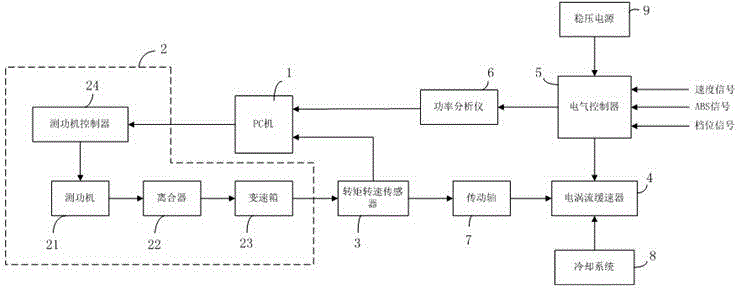

[0023] like figure 1 As shown, the test system includes a PC 1, a dynamometer system 2, a torque speed sensor 3, an eddy current retarder 4, an electrical controller 5 and a power analyzer 6, and the output of the PC 1 is connected to the The input end of the dynamometer system 2 is connected, the dynamometer system 2 is connected to the eddy current retarder 4 through the transmission shaft 7, and the torque speed sensor 3 is used to detect the eddy current retarder 4, the electrical controller 5 can collect control signals to control the output torque of the eddy current retarder 4, and the power analyzer 6 is used to collect the sampled values of the electrical controller 5 and feed them back to the PC Machine 1.

[0024] The dynamometer system 2 includes a dynamometer 21 , a clutch 22 , a gearbox 23 connected in sequence, and a dynamom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com