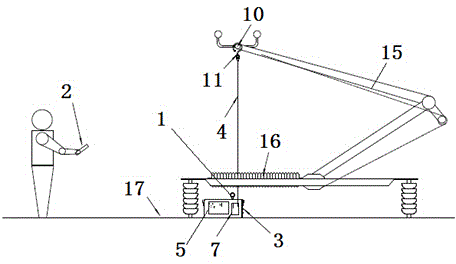

Detection method and system device for characteristics of locomotive pantograph

An inspection method, technology of pantograph, applied in the direction of using a device for measuring the time required to move a certain distance, a measuring device, using an optical device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

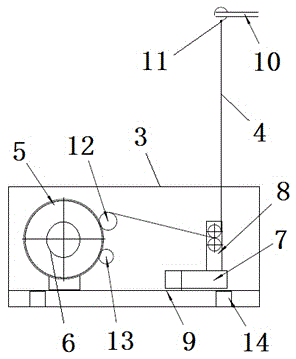

Examples

Embodiment 1

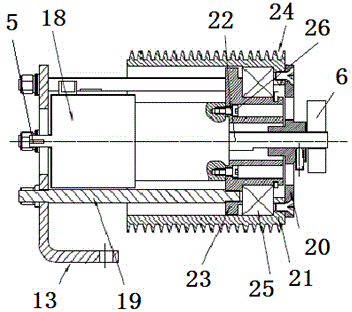

[0032] The take-up and pay-off mechanism includes a high-torque deceleration stepping drive motor 18, a motor mounting and fixing assembly 19, a sheave rotating assembly 20, a tension sensor 7 and a detection rope 4; the driving motor 18 is installed and fixed on the motor mounting and fixing assembly 19, The output shaft 22 of the drive motor 18 is connected through the transmission flange 23 to drive the sheave 21 of the sheave rotating assembly 20 to run. One end of the detection rope 4 is fixed on the wiring groove 24 on one side of the sheave 21, and the other end of the detection rope 4 passes through a tension The sensor 7 is connected to a hook 11 suspended on an upper shaft 10 at the top of the pantograph.

[0033] The sheave rotating assembly 20 is equipped with a rolling bearing 25, which is fixed by an interference fit between the outer ring of the rolling bearing 25 and the sheave 21, the inner ring of the rolling bearing 25 is in clearance fit with the motor mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com