Optical coupling device and forming method thereof

An optical coupling device and bonding technology, which is applied in the coupling of optical waveguides, semiconductor devices, electrical components, etc., can solve the problems of unfavorable optical waveguide device performance and low coupling efficiency, and achieve the effect of preventing mutual interference and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In the prior art three-dimensional packaging structure, grating coupling is usually used to realize the connection between the two planar optical waveguides on the silicon substrate. Since the grating coupling is not reflective coupling, the loss of light waves during the coupling process Larger, the coupling efficiency is very low, usually the grating coupling efficiency is only 20% to 70%.

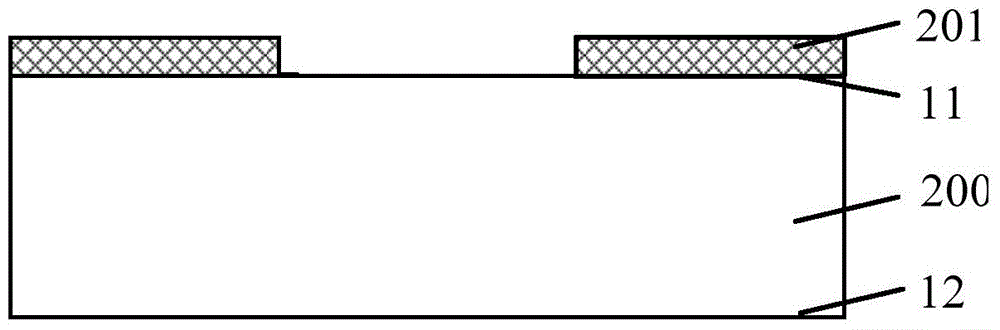

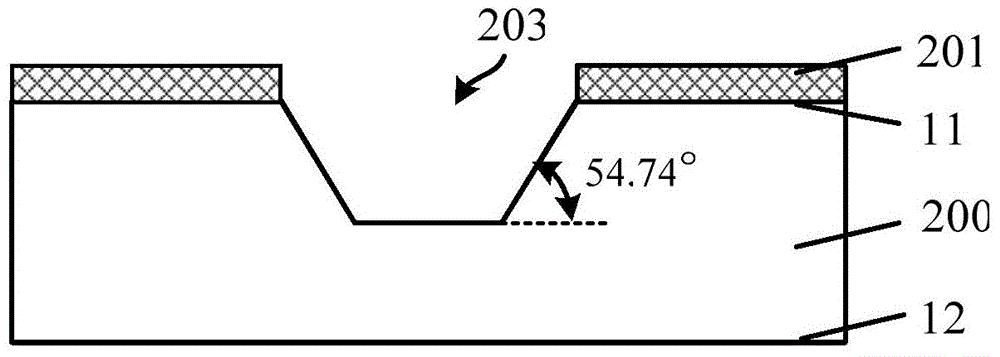

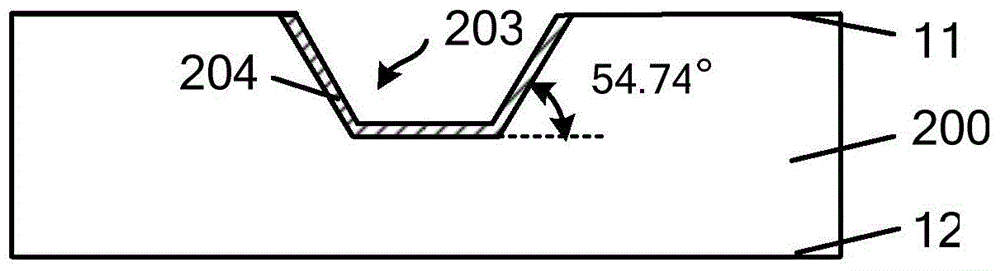

[0038] To this end, an embodiment of the present invention provides an optical coupling device and a method for forming the same. The coupling device of the present invention includes: a first semiconductor substrate and a second semiconductor substrate. The first groove on the first surface of the bottom, the sidewall of the first groove has a first inclination angle, the sidewall and the bottom surface of the first groove have a first reflective layer; the second semiconductor substrate has A second groove penetrating the third surface of the second semiconductor substrate, the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com