Transmission mechanism for permanent magnetic gear

A gear transmission, permanent magnet technology, applied in the direction of electromechanical transmission, electromechanical devices, electric components, etc., can solve the problems of the output speed cannot be constant, the output speed fluctuates, only the speed can be changed, etc., to increase the processing cost and manufacturing difficulty, operation Reliability reduction, permanent magnet saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

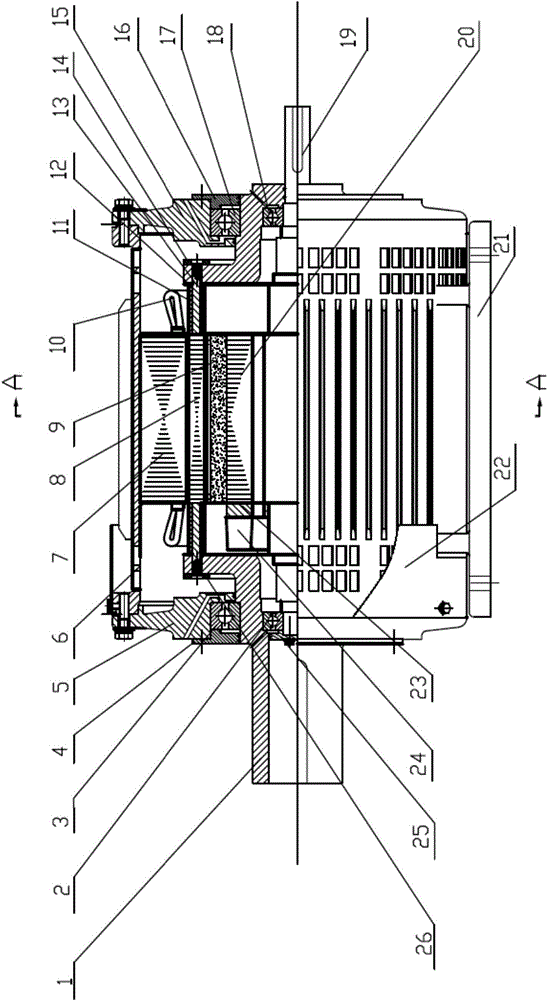

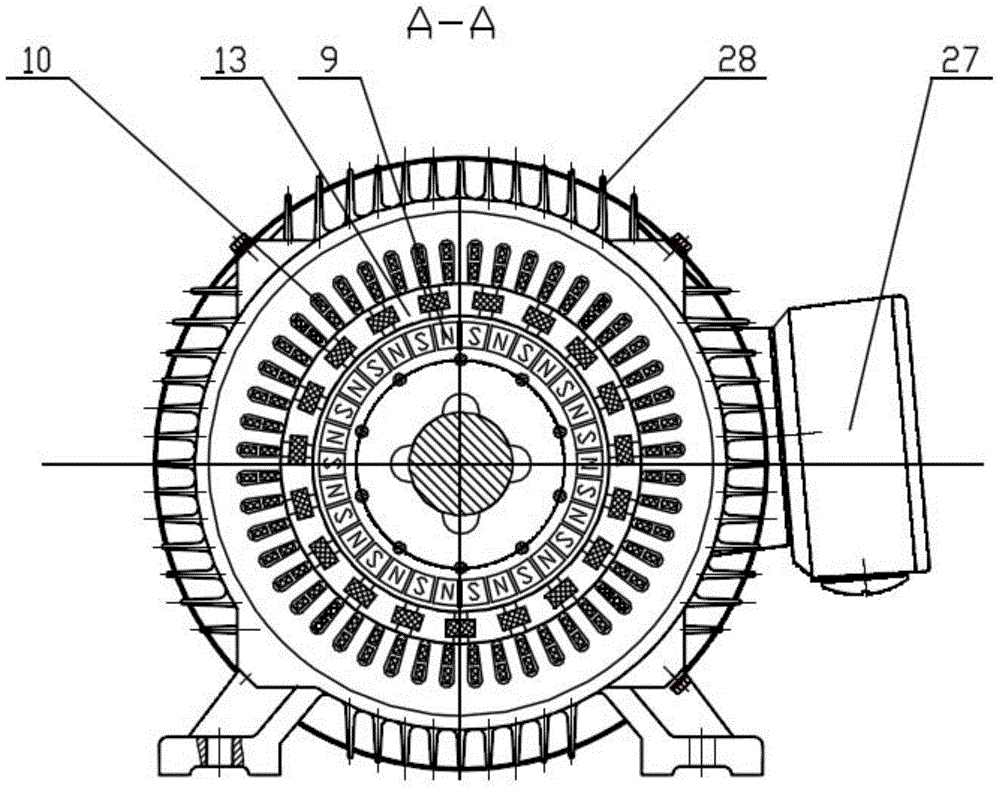

[0072] The present invention will be further described below in conjunction with the accompanying drawings.

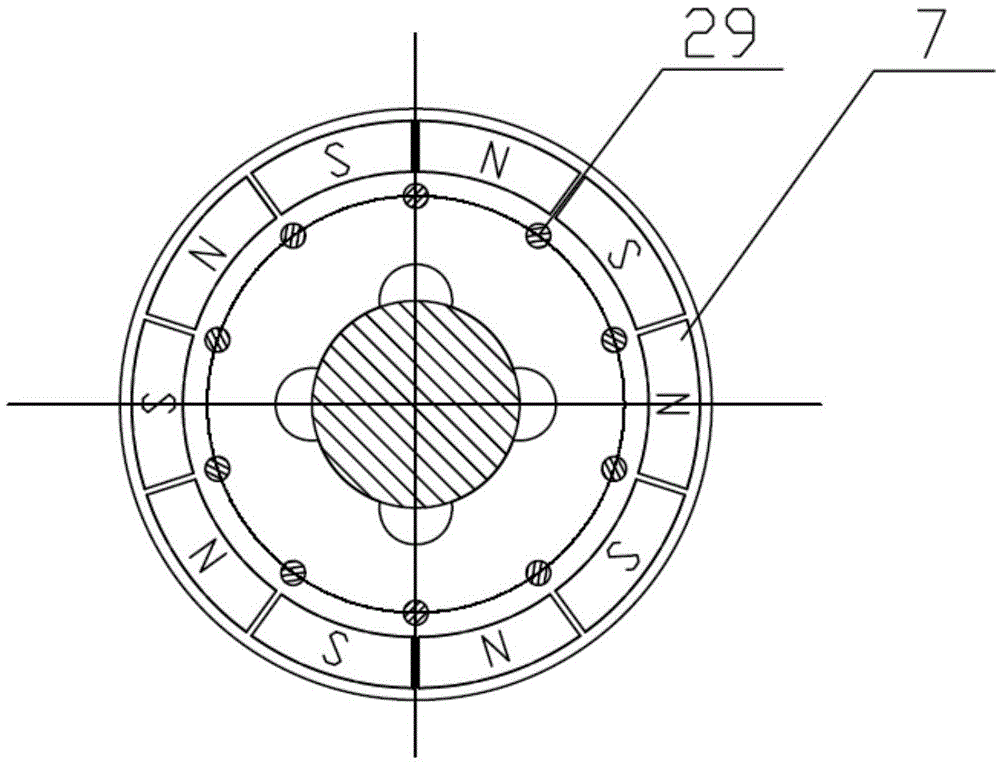

[0073] Such as Figure 1-7 As shown, a permanent magnet gear transmission device includes a stator assembly, a magnetic adjustment ring assembly, a rotor assembly and a casing assembly.

[0074] The stator assembly includes a stator core 7 and a stator winding 10; the stator core 7 is formed by laminating silicon steel sheets insulated on both sides, and the stator core 7 has slots with the same shape and uniform distribution; the stator winding 10 Embedded in the slot of the stator core 7, the stator winding 10 generates a rotating magnetic field when alternating current flows through it.

[0075] The stator core 7 and the casing 6 in the casing assembly are fixed by interference fit.

[0076] The stator core 7 is an outer stator core 7 or an inner stator core 7; when the stator core 7 is an outer stator core 7, the magnetic adjusting ring assembly and the rotor ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com