Method for measuring surface potentials on polarised devices

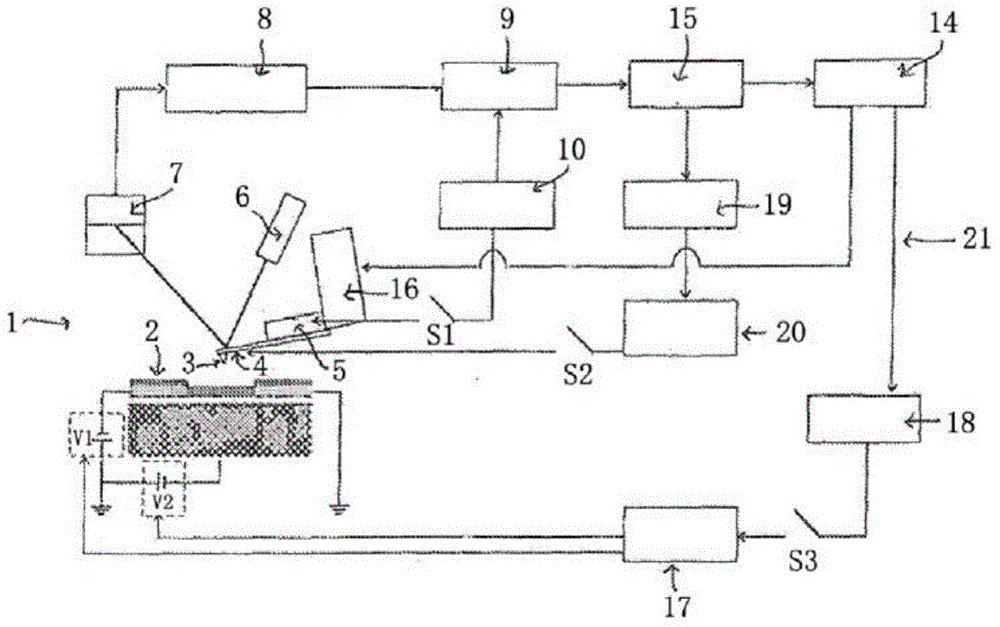

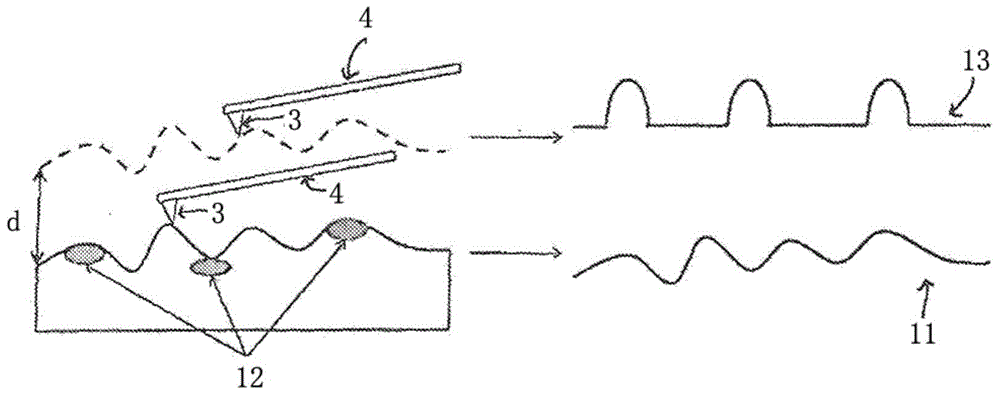

A technology of surface potential and equipment, which is applied in the field of potential and nanoscale potential mapping on electronic equipment, can solve the problems of inaccurate probe measurement, easy distortion of shape and contour, and the measurement device does not allow distinction, so as to achieve simple implementation and eliminate The effect of topographical illusions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

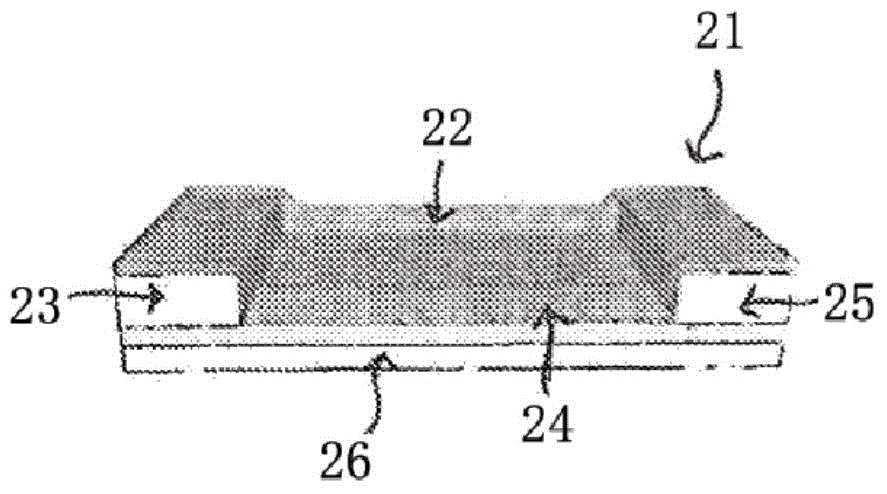

[0071] Example 1 : Demonstration of the method according to the invention on a polarized electronic device of the OFET type

[0072] The method has been implemented on polarized electronic devices, more specifically on OFET transistors (Organic Field Effect Transistors) 21, such as Figure 3A As shown, and wherein the semiconductor material 22 is composed of poly(3-hexylthiophene) or P3HT deposited on the electrode structure forming the transistor.

[0073] In particular, transistors of this type can withstand applied voltages up to ±100 V, which can cause problems when measuring their topographical profiles.

[0074] The OFET transistor 21 comprises three regions, namely 23 , 24 and 25 , which are associated.

[0075] More specifically, region 23 corresponds to a potentiostatic "drain" electrode, intermediate region 24 corresponds to the channel of transistor 21, and region 25 corresponds to a potentiostatic "source" electrode.

[0076] Polarization of transistor 21 is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com