A control circuit of desktop automatic rubber encapsulation equipment

A device control and circuit technology, applied in packaging automatic control, circuit, program control, etc., can solve problems such as low efficiency and unguaranteed packaging efficiency, and achieve the effect of convenient operation, easy adjustment, and guaranteed running rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with accompanying drawing.

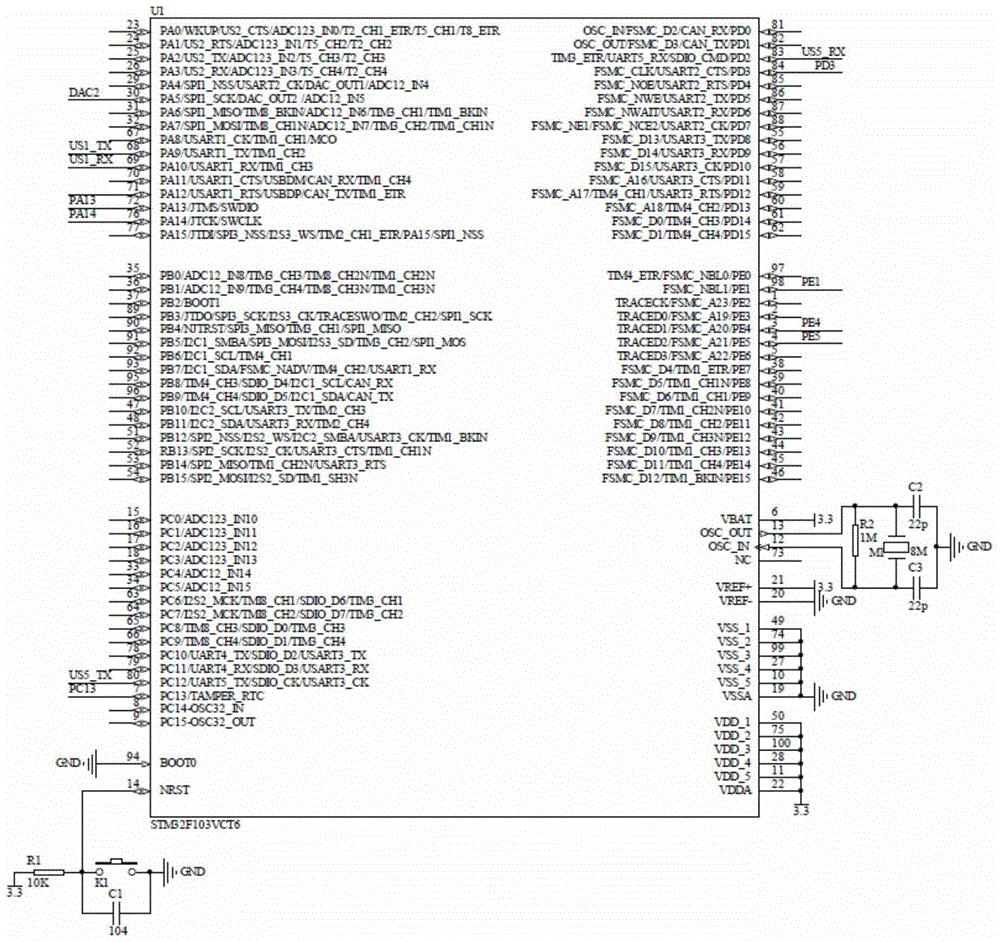

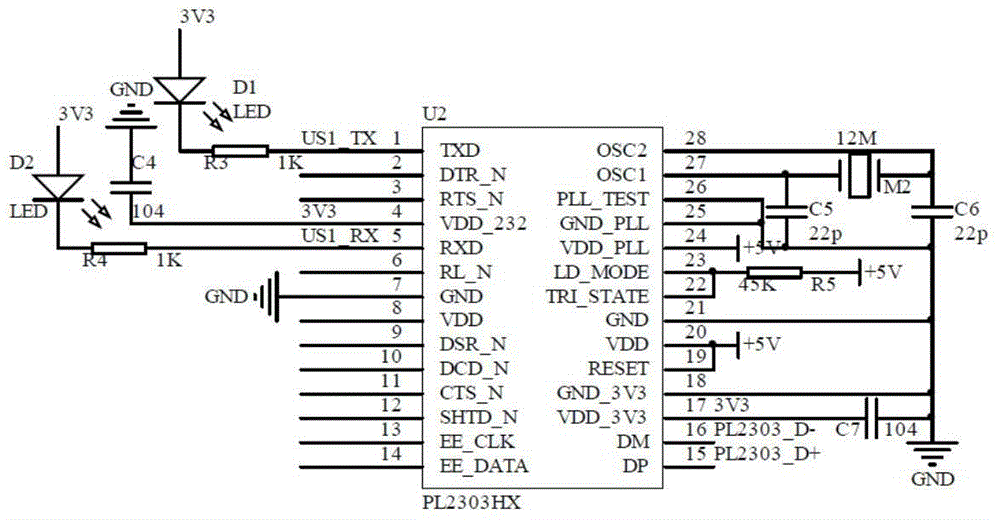

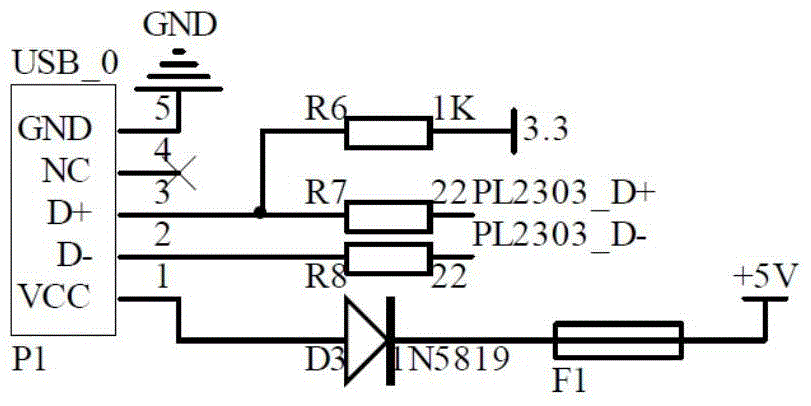

[0044] Such as Figure 1 to Figure 15 As shown, a control circuit for desktop automatic rubber encapsulation equipment, including the minimum system circuit of single chip microcomputer, PL2303 circuit, serial port debugging circuit, voltage input circuit, switching power supply step-down circuit, voltage transformation circuit, touch screen communication circuit, servo motor control circuit, Switch circuit, signal indicator circuit, power indicator circuit, download interface circuit, buzzer circuit, filter circuit.

[0045] Such as figure 1 As shown, the minimum system circuit of the single chip microcomputer includes control chip U1 (model: STMB32F103VCT6), button K1, resistor R1, resistor R2, capacitor C1, capacitor C2, capacitor C3, crystal oscillator Y1; the power supply pins (6, 21, 50, 75, 100, 28, 11, 22 pins) to 3.3V external power supply; the grounding pins (94...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com