A kind of molybdenum oxide nanofiber paper and preparation method thereof

A nanofiber and molybdenum oxide technology, which is applied in the direction of molybdenum oxide/molybdenum hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of different lengths of molybdenum oxide nanofibers, affecting product performance, and large consumption of raw materials, etc., to achieve excellent Sensitive properties, strong practicability, and the effect of less raw material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

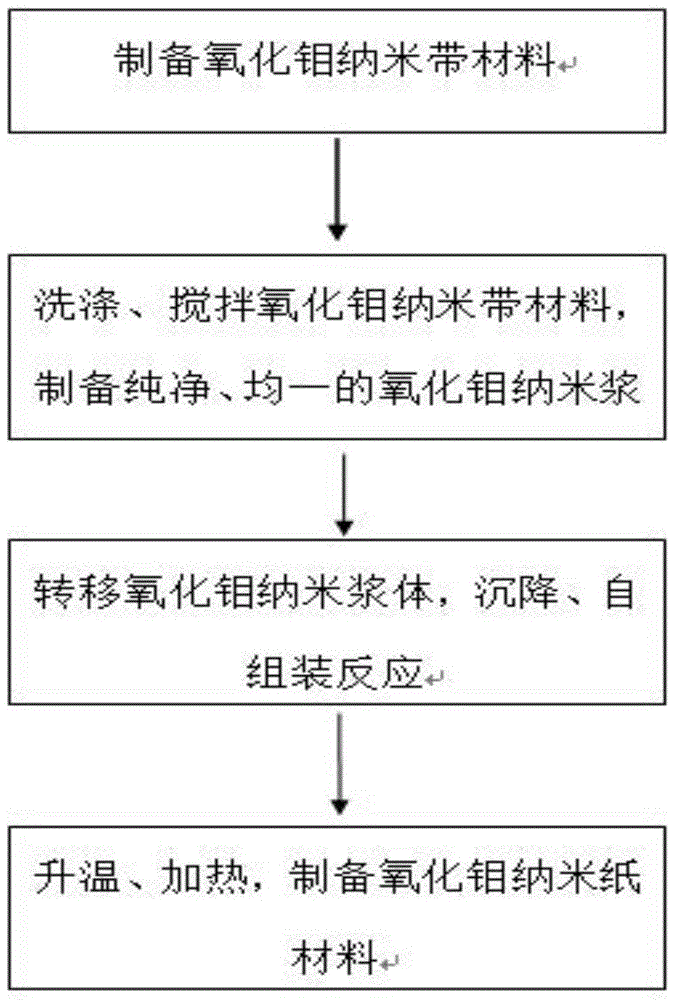

[0046] A preparation method of molybdenum oxide nanofiber paper, said method comprising the steps of:

[0047] (1) Dissolve 2.42g of sodium molybdate dihydrate in 30.0ml of deionized water to obtain a sodium molybdate solution, and then add dropwise 6.25ml of a concentrated solution with a concentration of 70% and a purity greater than 99% to the sodium molybdate solution. Nitric acid, magnetically stirred for 30 minutes under sealed conditions, and obtained solution A after stirring evenly;

[0048] (2) Under normal temperature and pressure conditions, dissolve 150.ml of absolute ethanol in 1350.0ml of deionized water, and stir magnetically for 15 minutes under sealed conditions. After stirring evenly, a mixed solution B of alcohol and deionized water is obtained;

[0049] (3) Under normal temperature and pressure conditions, transfer the solution A obtained in step (1) to a clean polytetrafluoroethylene reactor, then place the reactor in an electric blast drying oven, and co...

Embodiment 2

[0055] The difference between the preparation method of molybdenum oxide nanofiber paper in this example and Example 1 is that the temperature in the drying box in step (3) of this example is 260 ° C, and the drying of molybdenum oxide nanofiber paper in step (6) The temperature was 80° C., and other conditions were the same as in Example 1 to prepare the molybdenum oxide nanofiber paper.

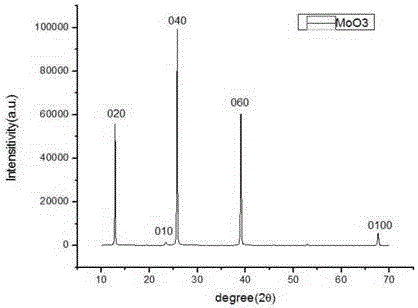

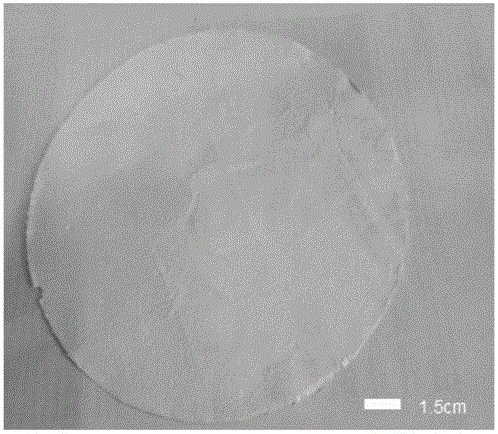

[0056] The X-ray diffraction pattern of the molybdenum oxide nanofiber paper prepared in this embodiment is as follows figure 2 As shown, the SEM image is shown in Figure 4 As shown, the actual picture is as Figure 11 As shown, the cross-sectional view is as Figure 12 shown.

Embodiment 3

[0058] A preparation method of molybdenum oxide nanofiber paper, said method comprising the steps of:

[0059] (1) Dissolve 2.42g of sodium molybdate dihydrate in 30.0ml of deionized water to obtain a sodium molybdate solution, and then add 15.0ml of a concentrated solution with a concentration of 70% and a purity greater than 99% to the sodium molybdate solution dropwise. Nitric acid, magnetically stirred for 30 minutes under sealed conditions, and obtained solution A after stirring evenly;

[0060] (2) Under normal temperature and pressure conditions, dissolve 150.ml of absolute ethanol in 1350.0ml of deionized water, and stir magnetically for 15 minutes under sealed conditions. After stirring evenly, a mixed solution B of alcohol and deionized water is obtained;

[0061] (3) Under normal temperature and pressure conditions, transfer the solution A obtained in step (1) to a clean polytetrafluoroethylene reactor, then place the reactor in an electric blast drying oven, and co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com