A large-scale simulated granite porcelain thin plate and its preparation method

A granite and large-scale technology, applied in glass manufacturing equipment, manufacturing tools, glass molding, etc., can solve the problems of imitation granite tiles, such as heavy weight, small bumps on the surface, and not realistic enough, to achieve good antifouling effect and large specifications , Easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] 1) Preparation of surface glaze layer slurry

[0059] Material ratio of glaze layer composition: SiO 2 60.2wt%, Al 2 o 3 26.3wt%, Fe 2 o 3 0.1wt%, TiO 2 0.1%, CaO0.3wt%, MgO0.2wt%, K 2 O4.5wt%, Na 2 O2.8wt%, P 2 o 5 0.3wt%, ZrO 2 5.2wt%;

[0060] The solvent in the slurry is water, the specific gravity is 1.40g / ml, spray 362g / m 2 ;

[0061] 2) Preparation of transparent glaze layer slurry

[0062] Material ratio of transparent glaze layer composition: SiO 2 55.8wt%, Al 2 o 3 14.1wt%, Fe 2 o 3 0.1wt%, TiO 2 0.1%, CaO12.7wt%, MgO3.2wt%, K 2 O1.7wt%, Na 2 O0.3wt%, IL7.6wt%, ZnO3.5wt%;

[0063] The solvent in the slurry is water, the specific gravity is 1.45g / ml, spray 206g / m 2 ;

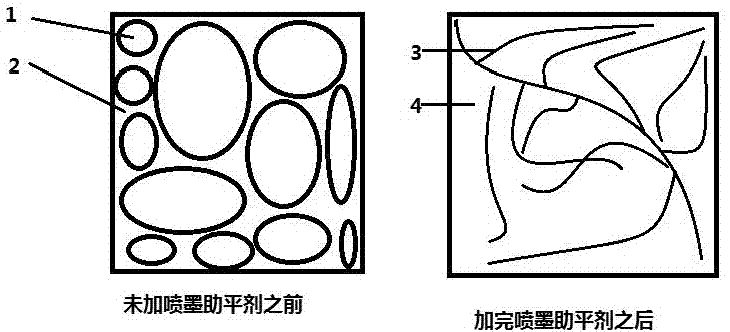

[0064] Add the inkjet leveling agent perfluorooctane sulfonate amine to the transparent glaze layer slurry, in terms of mass percentage, it is 0.3% of the transparent glaze layer slurry quality;

[0065] 3) The ink is produced by FERRO company, including cyan: BL511; yello...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com