Biomass pellet forming system

A particle forming and biomass technology, which is applied in the fields of biofuel, mold extrusion granulation, waste fuel, etc., can solve the problems of time-consuming, unfavorable particle forming, and unfavorable full utilization of energy, and achieve the effect of improving processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the biomass pellet forming system of the present invention will be described in detail below with reference to the accompanying drawings.

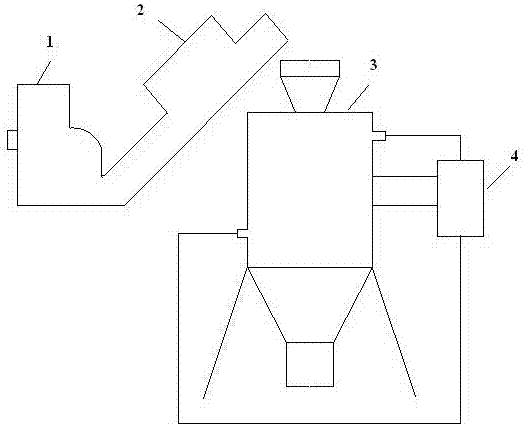

[0026] figure 1 The biomass particle forming system shown is composed of a biomass crushing device 1 , a crushed material drying device 2 , a material particle forming device 3 and a heat pump device 4 .

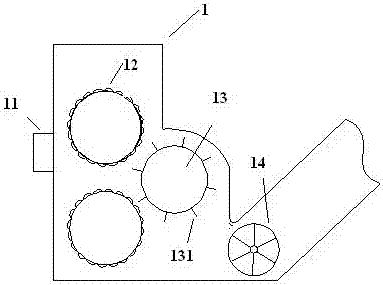

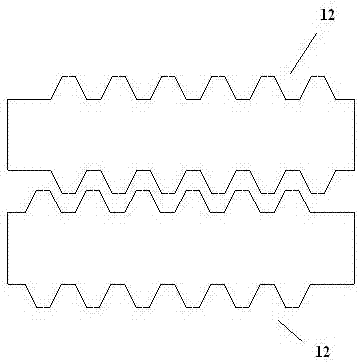

[0027] The biomass pulverizing device crushes and pulverizes the biomass material. Such as figure 2 As shown, viewed from the moving direction of biomass, the biomass pulverizing device includes a feeder 11 , a pair of rolling rollers 12 , pulverizing rollers 13 , and a discharge fan 14 in sequence. The feeder 11 is a pipe with a U-shaped cross section, and the biomass material enters the biomass crushing device 1 from the feeder for crushing. The rolling rollers 12 are arranged symmetrically up and down in pairs, and are used for rolling the biomass. And if image 3 As shown, the rolling roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com