Horizontal multi-layer double circulating air rotary multifunctional metal workpiece heat treatment furnace structure

A technology for metal workpieces and heat treatment furnaces, which is applied in the field of solution and aging heat treatment of high-end aluminum alloy workpieces, and can solve the problem of increasing site use costs, equipment manufacturing costs and maintenance costs, large temperature difference distribution on the surface of workpieces, and overburning of surface temperature. problems, to achieve the effect of reducing the cost of land use and operation and maintenance of the workshop, uniform and stable heating temperature or cooling temperature, and reducing the oxidation of the workpiece surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

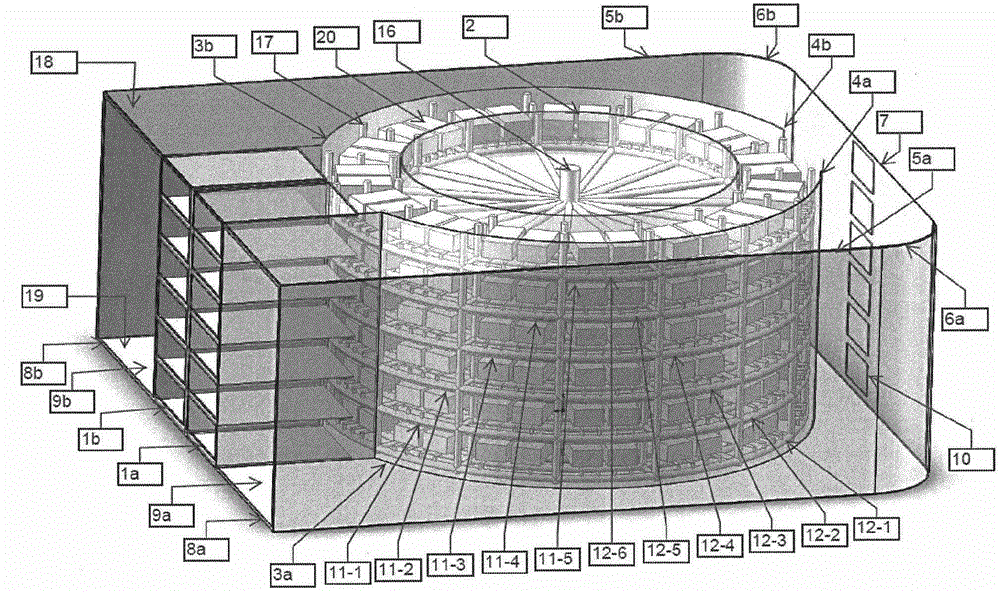

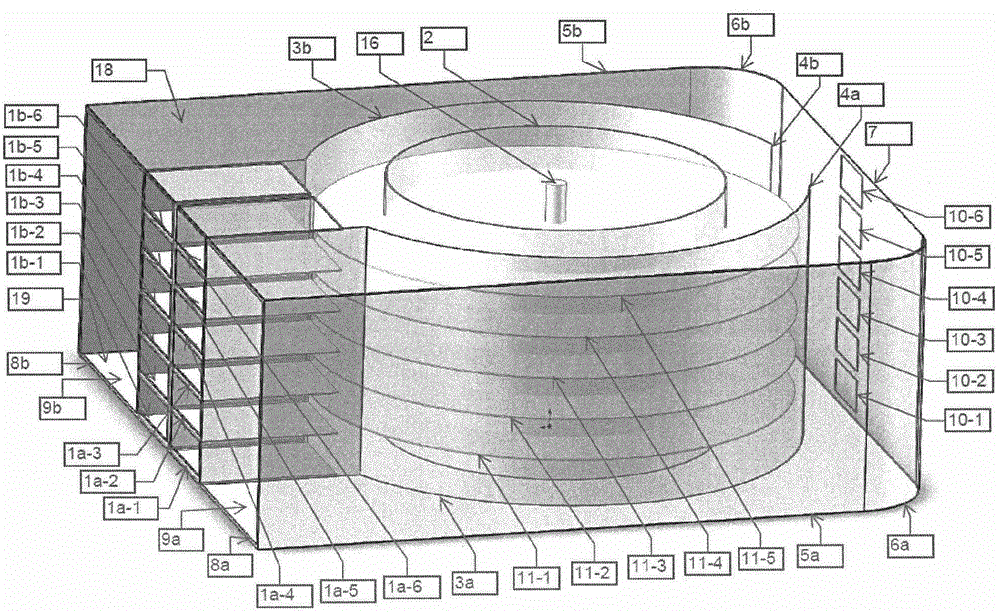

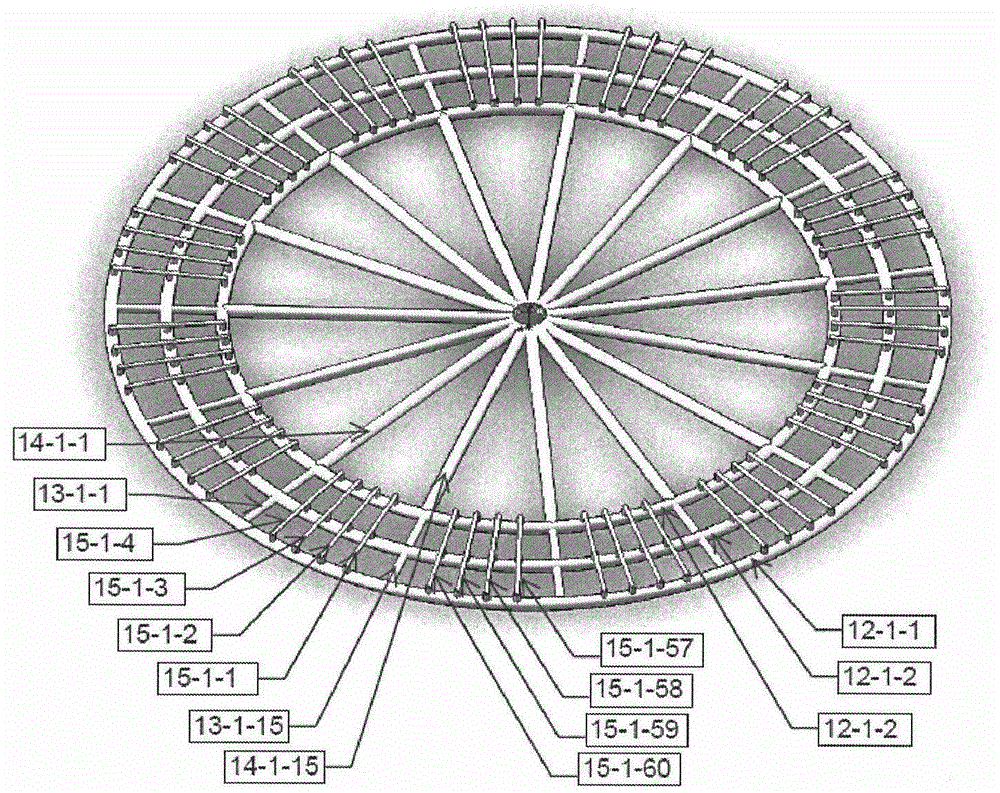

[0062] The specific implementation of the present invention discloses a "horizontal multi-layer double-circulation air rotary multifunctional metal workpiece heat treatment furnace structure" suitable for the field of heating and heat treatment of metal workpieces, especially the field of rapid, uniform and low-energy heat treatment of aluminum alloy workpieces

[0063] The key technical problem to be solved is that the dual-circulation air is respectively supplied to the heating zone and heat preservation zone or air quenching zone of the solid solution furnace and the aging furnace of the aluminum alloy workpiece, and the air supply is uniformly distributed and flows at a high speed, and the metal workpiece is heated or cooled quickly and uniformly, minimizing the Small air flow resistance, efficient use of circulating air, effective control of furnace door air and suction, high-efficiency and low-consumption heating and heat treatment of heat-treated metal workpieces, especia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com