Chemical vapor deposition apparatus

A technology of chemical vapor deposition and gas shower head, which is applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of substrate tray damage, increase of heater cost, radiation heat loss, etc., and achieve Reduce power and temperature requirements, prolong service life, and reduce radiation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention discloses a chemical vapor deposition device. In order to make the above objects, features and advantages of the present invention more obvious and easy to understand, the specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

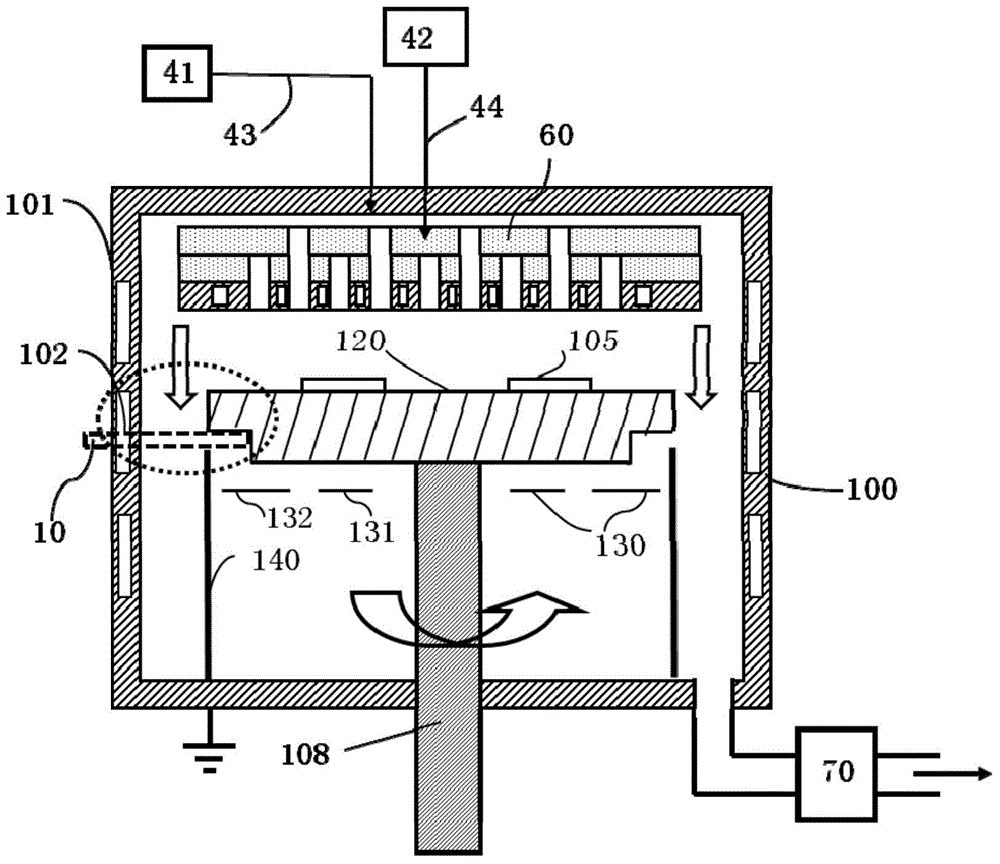

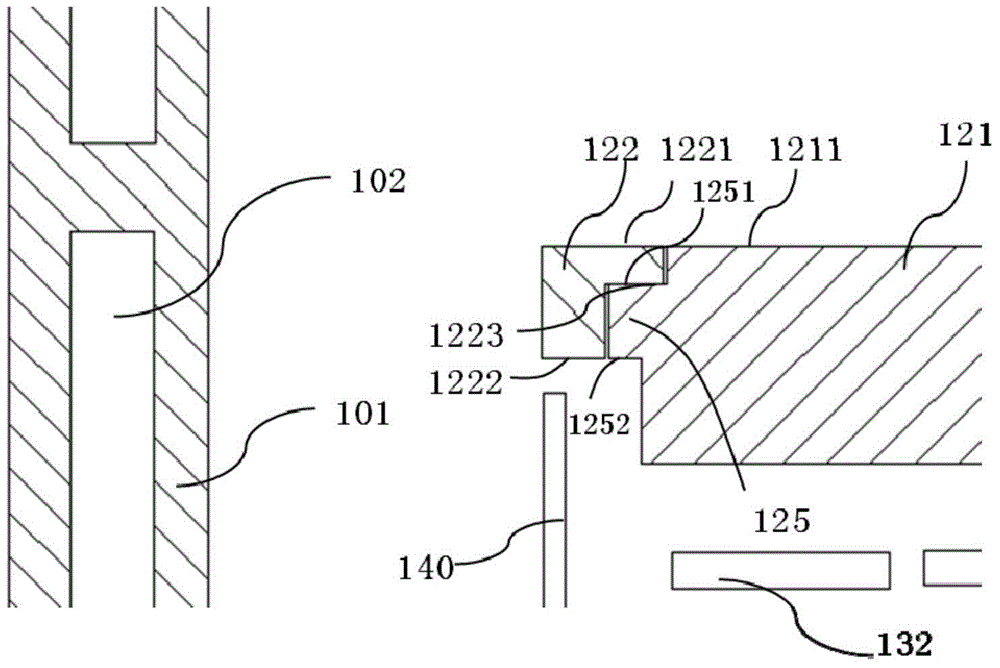

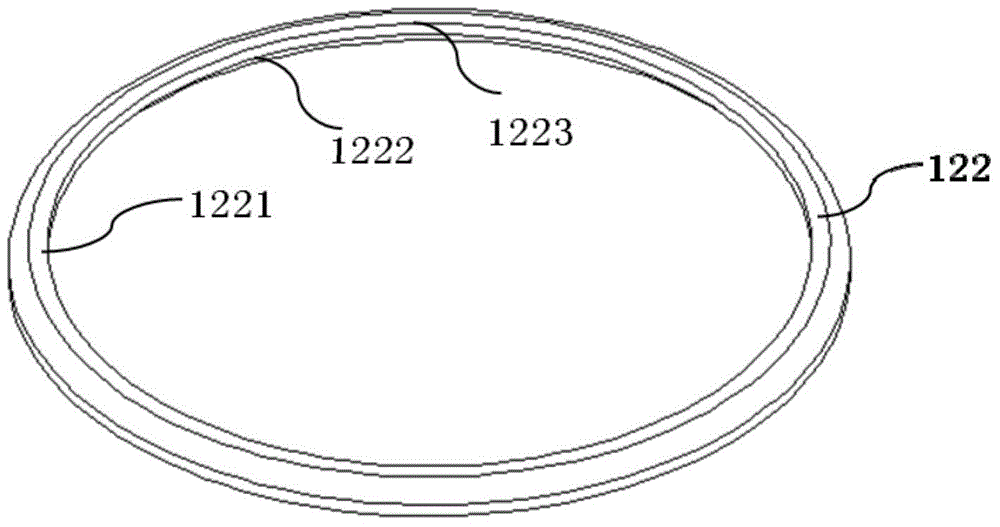

[0024] figure 1 A schematic structural view of the chemical vapor deposition device of the present invention is shown, the device includes a reaction chamber 100, the reaction chamber 100 includes a reaction chamber side wall 101 surrounding the reaction chamber 100, and the reaction chamber 100 also includes a rotating shaft 108, which is placed A substrate tray 120 with a plurality of substrates 105 is mounted on the top of the rotating shaft 108 , and a heater 130 is located below the substrate tray 120 and is arranged around the rotating shaft 108 . The top of the reaction chamber 100 includes a gas shower head 60 for uniformly distr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com