Yacht engine cabin vibration absorber

A technology for engine rooms and yachts, applied in the field of yachts, can solve the problems of deformation, tearing or aging, falling to the ground, reducing the use function and life, and achieving the effect of convenient use and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

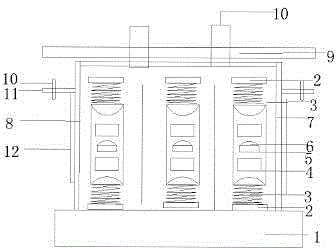

[0009] detailed description: Reference attached figure 1 , including a base 1, a shock absorbing port 2, a spring 3, a first baffle 8, and a second baffle 7, wherein the first baffle 8 and the second baffle 7 form a lateral space limiting space and are vertically and fixedly connected to the support plate 9, At least a part of the first baffle plate 8 and the second stop block 7 are inserted into the lateral space to limit the lateral displacement of the support plate 9, and the two ends of the first baffle plate 8 and the second block 7 are connected to the first baffle plate 8 by self-tapping bolts. A buffer plate 11 and a second buffer plate 12 are respectively fixedly connected, the middle of the shock absorber is the piston 3, the upper and lower ends of the piston 6 are provided with springs 3, and the ring at the bottom of the spring 3 is connected with the piston 6 through the sharp part, and the inside of the piston 6 Two disc magnets 4 are set.

[0010] Further, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com