Thin layer plate dipping device based on programmable controller

The technology of dipping device and thin-layer plate is applied in the field of thin-layer chromatography, which can solve the problems of increasing the workload of operators, affecting the accuracy of the color reaction on the thin-layer plate, and inability to accurately control the immersion time, so as to reduce labor costs. , the effect of improving accuracy and repeatability, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

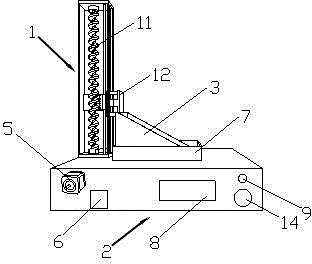

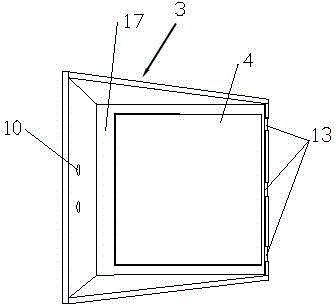

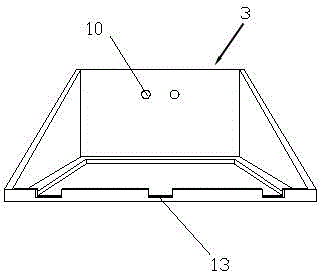

[0036] Such as figure 1 As shown, a thin-layer plate impregnation device based on a programmable controller, the device includes a screw slide 1 and a base 2, the screw slide 1 and the base 2 are vertically connected, and the screw slide Table 1 is provided with screw rod 11 and slide block 12, and described slide block 12 is provided with thin-layer board lifting table 3, and described thin-layer board lifting table includes bottom plate 17 for placing thin-layer board, and described bottom plate 17 is provided with There is a hollow structure 4, a stepper motor 5 and a stepper motor drive module 6 for controlling the rotation of the screw rod 11 are arranged under the screw slide 1; Corresponding dipping liquid storage tank 7, Arduino control module 8 is arranged in described base 2, and switch 9 is also arranged on described base 2, and described stepper motor drive module 6, Arduino control module 8, described switch 9 phases connection, the base 2 is also provided w...

Embodiment 2

[0048] Such as Figure 4 As shown, a thin-layer plate impregnation device based on a programmable controller, the device includes a screw slide 1 and a base 2, the screw slide 1 and the base 2 are vertically connected, and the screw slide Table 1 is provided with screw rod 11 and slide block 12, and described slide block 12 is provided with thin-layer board lifting table 3, and described thin-layer board lifting table includes bottom plate 17 for placing thin-layer board, and described bottom plate 17 is provided with There is a hollow structure 4, a stepper motor 5 and a stepper motor drive module 6 for controlling the rotation of the screw rod 11 are arranged under the screw slide 1; Corresponding dipping liquid storage tank 7, Arduino control module 8 is arranged in described base 2, and switch 9 is also arranged on described base 2, and described stepper motor drive module 6, Arduino control module 8, described switch 9 phases connection, the base 2 is also provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com