Laser module group with controllable power

A laser module and power technology, which is applied in the direction of the device for controlling the output parameters of the laser, can solve the problems of complex structure, difficulty in large-scale production, and cumbersome process of the power controllable laser module, so as to improve mass production efficiency and accurate power The effect of simple control and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

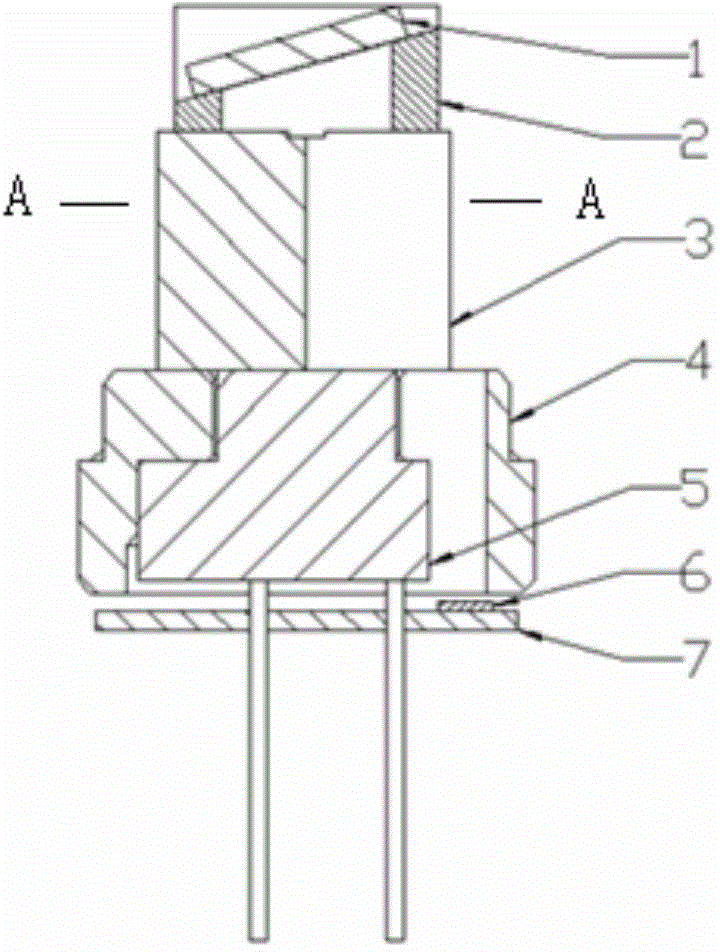

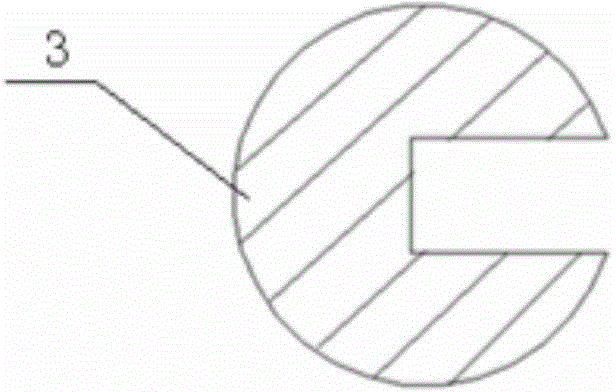

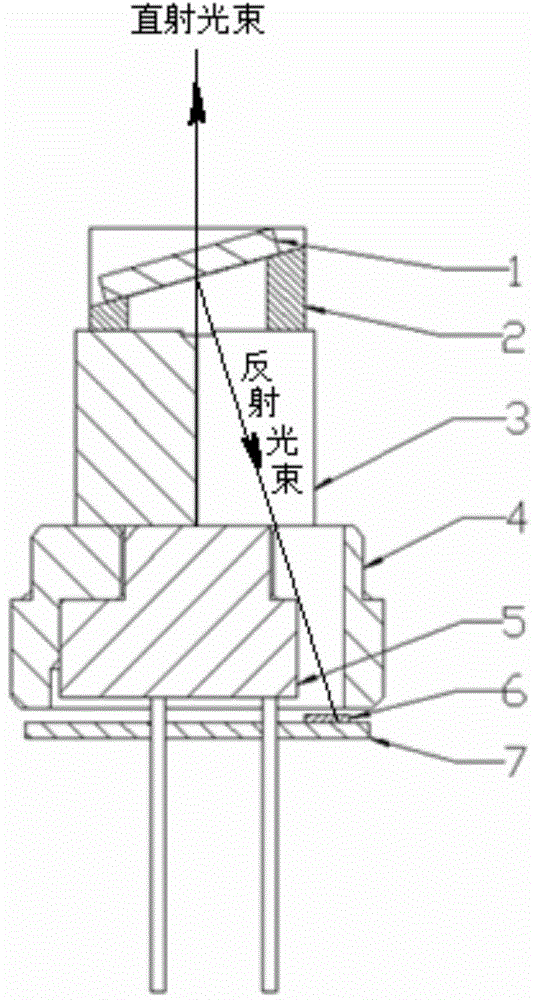

[0012] like figure 1 , 2 As shown, a power controllable laser module includes LD5, LD driver board 7, sensor 6, bearing seat 4, photoresist crystal 3, transflective glass sheet 1 and bracket 2, and the bottom surface of the bearing seat 4 is set The light transmission hole, the LD5 is installed in the bearing seat 4; the sensor 6 is welded on the LD driving board 7, and the LD driving board 7 is installed under the bearing seat 4, and the sensor 6 and The light-transmitting hole corresponds; the light-resist crystal 3 is mounted on the LD5, and a gap is set on the light-resist crystal 3, and the gap corresponds to the light-transmitting hole; the bracket 2 is installed on the On the optical glue crystal 3, the semi-transparent and semi-reflective glass sheet 1 is installed on the support 2, and the semi-transparent and semi-reflective glass sheet 1 forms a certain angle with the laser beam emitted by the LD5 to make the semi-transparent and semi-reflective glass sheet 1 form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com