Multi-centrifugal sheet combined type speed controller and brushless motor

A brushless motor and governor technology, applied in electrical components, electromechanical devices, magnetic circuit shape/style/structure, etc., to achieve the effect of improving the speed regulation effect, the speed regulation range is balanced and efficient, and suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

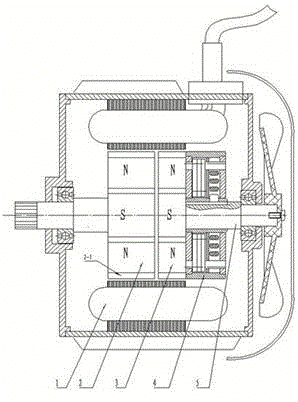

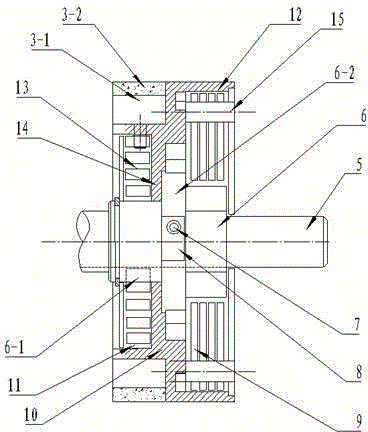

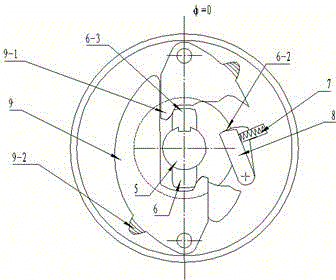

[0018] see figure 1 and figure 2 , this is a permanent magnet brushless motor with infinitely variable speed inner rotor: stator, casing, end cover, the same as ordinary brushless motors, the driving rotor 2 is placed at the output end of the motor shaft, the speed regulating rotor 2 and the governor 3 are placed after driving the rotor. The driving rotor 2 is provided with permanent magnets 2-1 in the circumferential direction, so that the polarities are periodically distributed according to N and S. The driving rotor 2 occupies most of the air gap of the stator, undertakes the main function of energy conversion, and is fixedly connected with the rotor shaft 1. The rotor shaft 1 outputs mechanical torque; the yoke 3-1 of the speed-regulating rotor 3 is provided with permanent magnets 3-2 along the circumferential direction, and the polarities are periodically distributed according to N and S, and their magnetic flux corresponds to the rest of the stator air gap . The spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com