Oral implant with asymmetric thread structure

An oral implant and implant technology, applied in the fields of implantology, medical science, dentistry, etc., can solve problems such as decreased stability of implants, increased stress at the bone interface, and bone fatigue damage, so as to avoid implant fracture, The effect of large bite force and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

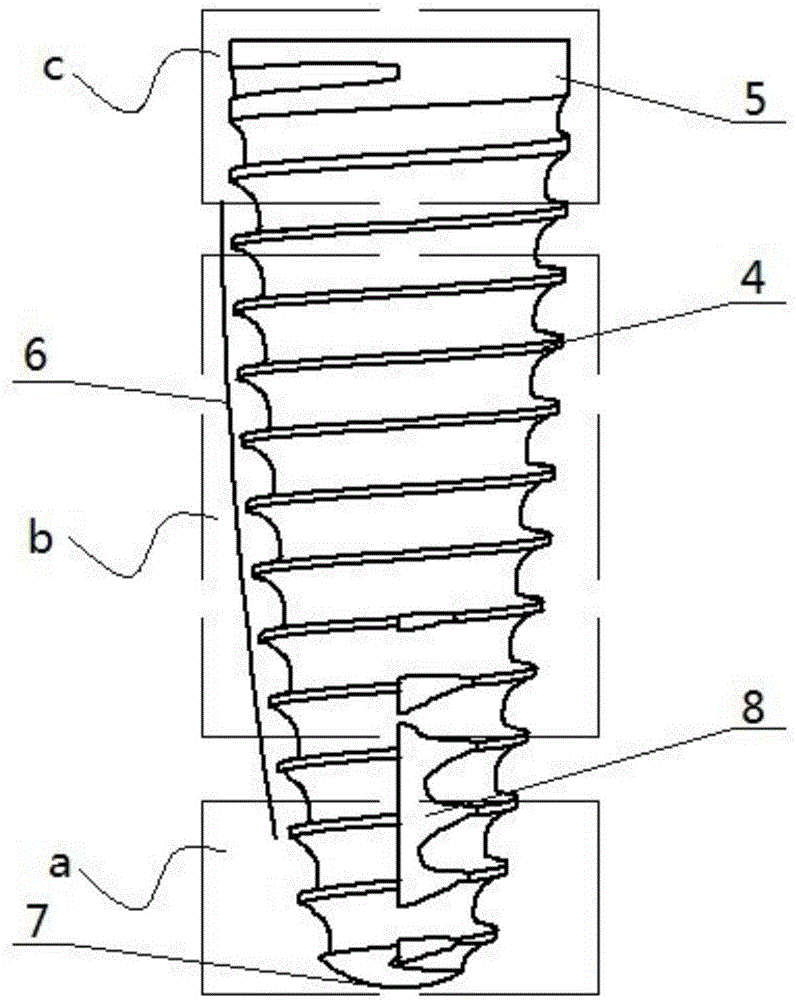

[0019] Through the following specific examples, combined with Attached picture , to further explain the technical solution of the present invention.

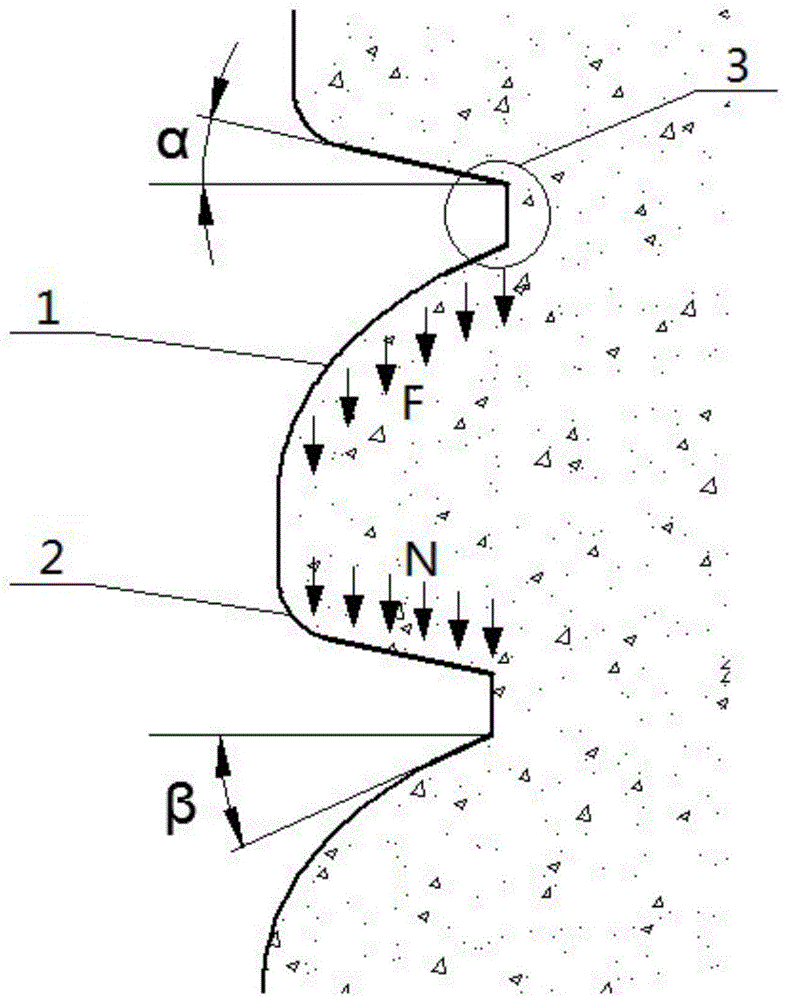

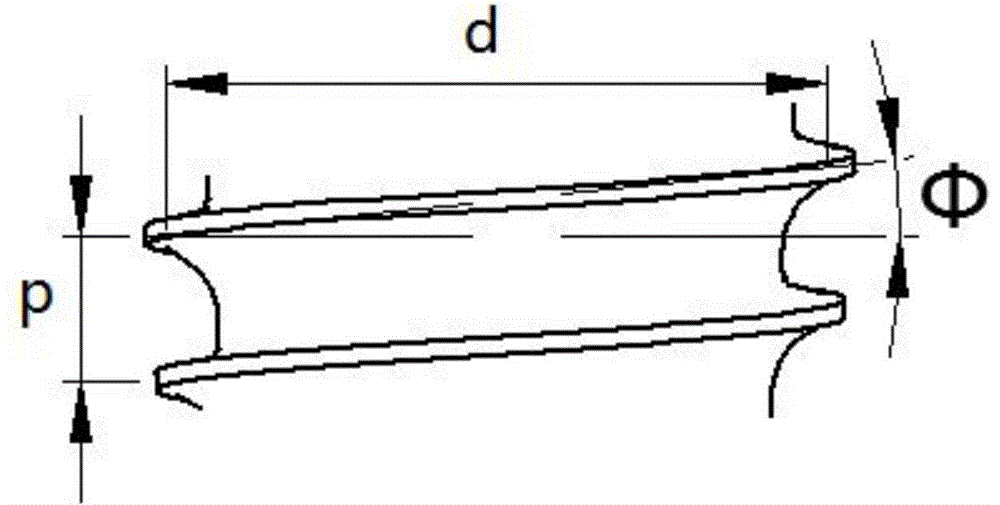

[0020] Such as figure 1 As shown, the present invention is an asymmetric thread structure for oral implants. The angle between the upper edge of the thread and the horizontal plane is α, and the size of α is 10°-20°. The upper edge has a supporting force N to the surrounding bone. A smaller angle can better support the upper bone while ensuring Good retention. The angle between the lower edge and the horizontal plane is β, and the size of β is 30° to 40°. During the use of the implant, the occlusal force F is transmitted to the surrounding bone through the lower edge of the implant thread. A larger angle makes The occlusal force is distributed to different layers of bone, effectively dispersing the occlusal force and avoiding the stress concentration of the bone. The radius of the arc surface 1 at the transition between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com