Patents

Literature

60 results about "Compact Bones" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Compact bone, also called cortical bone, dense bone in which the bony matrix is solidly filled with organic ground substance and inorganic salts, leaving only tiny spaces (lacunae) that contain the osteocytes, or bone cells.

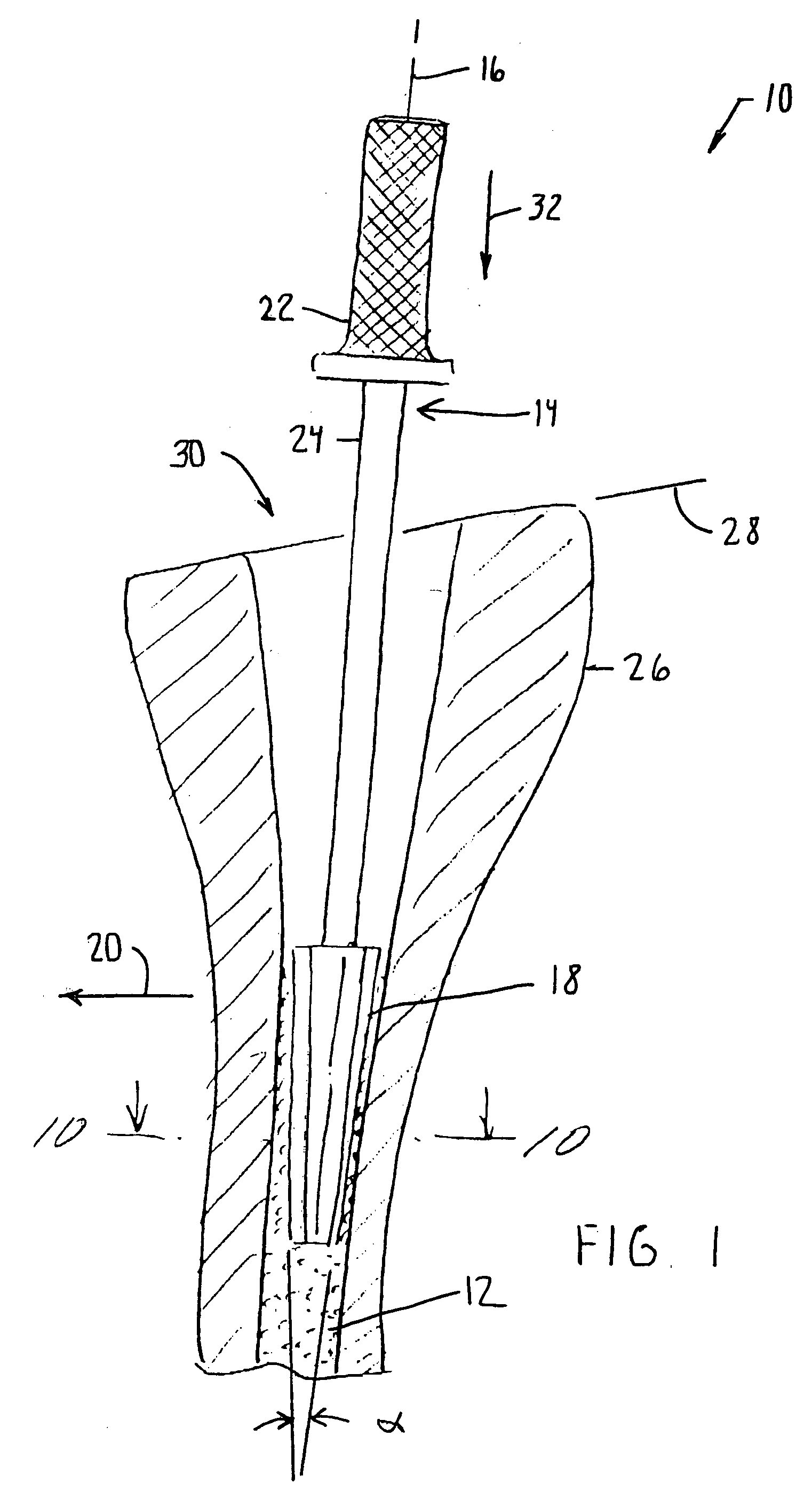

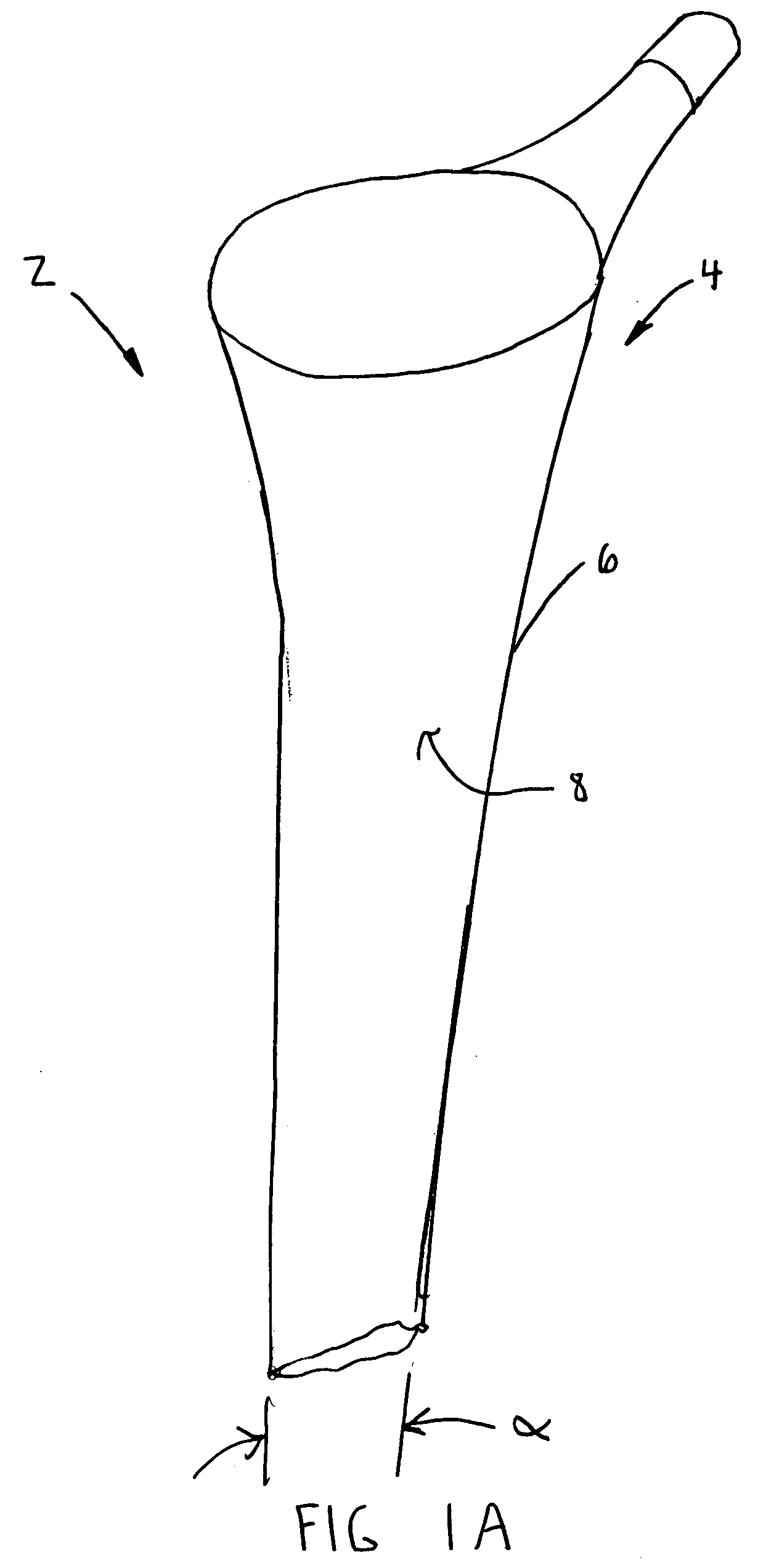

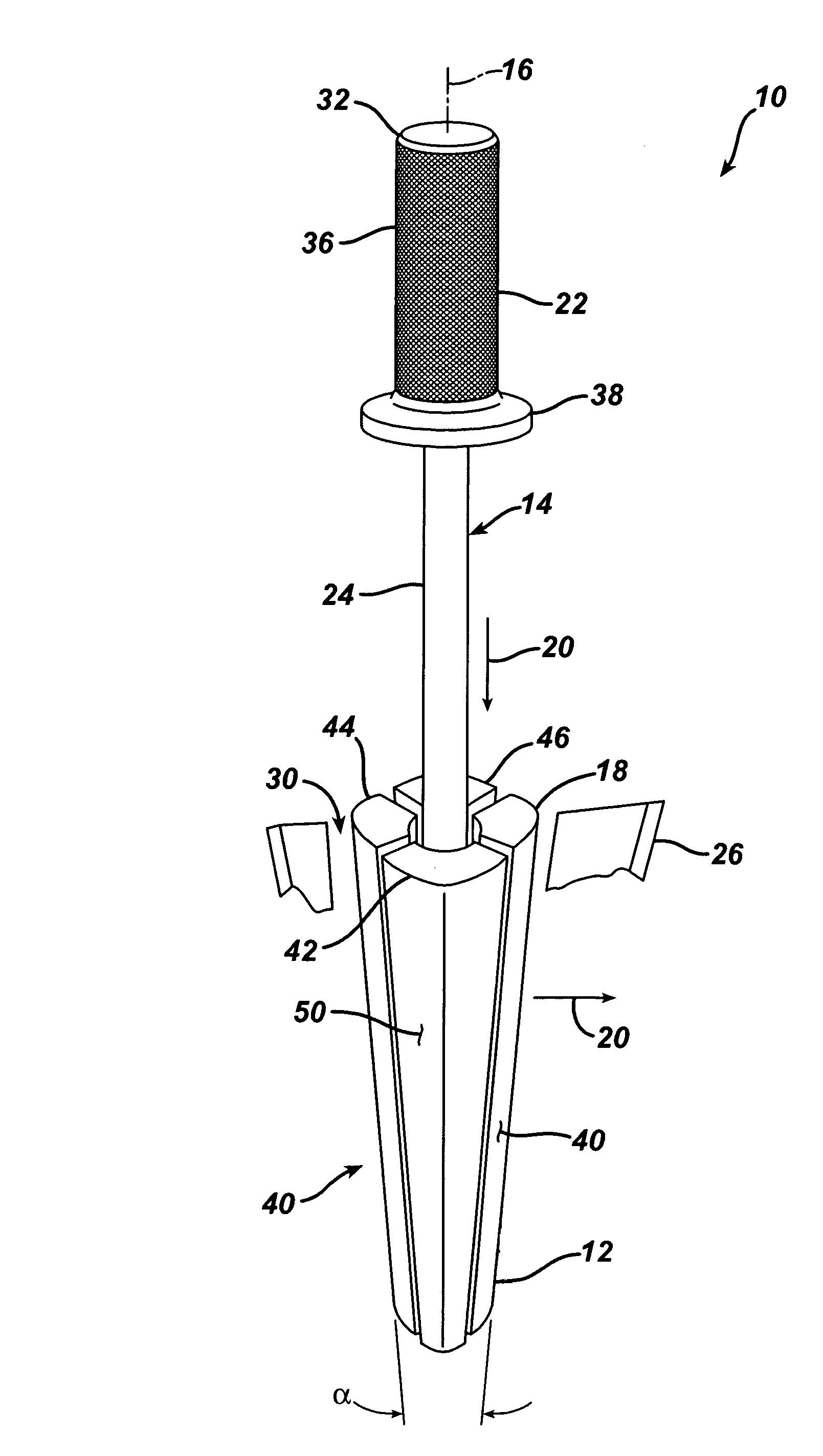

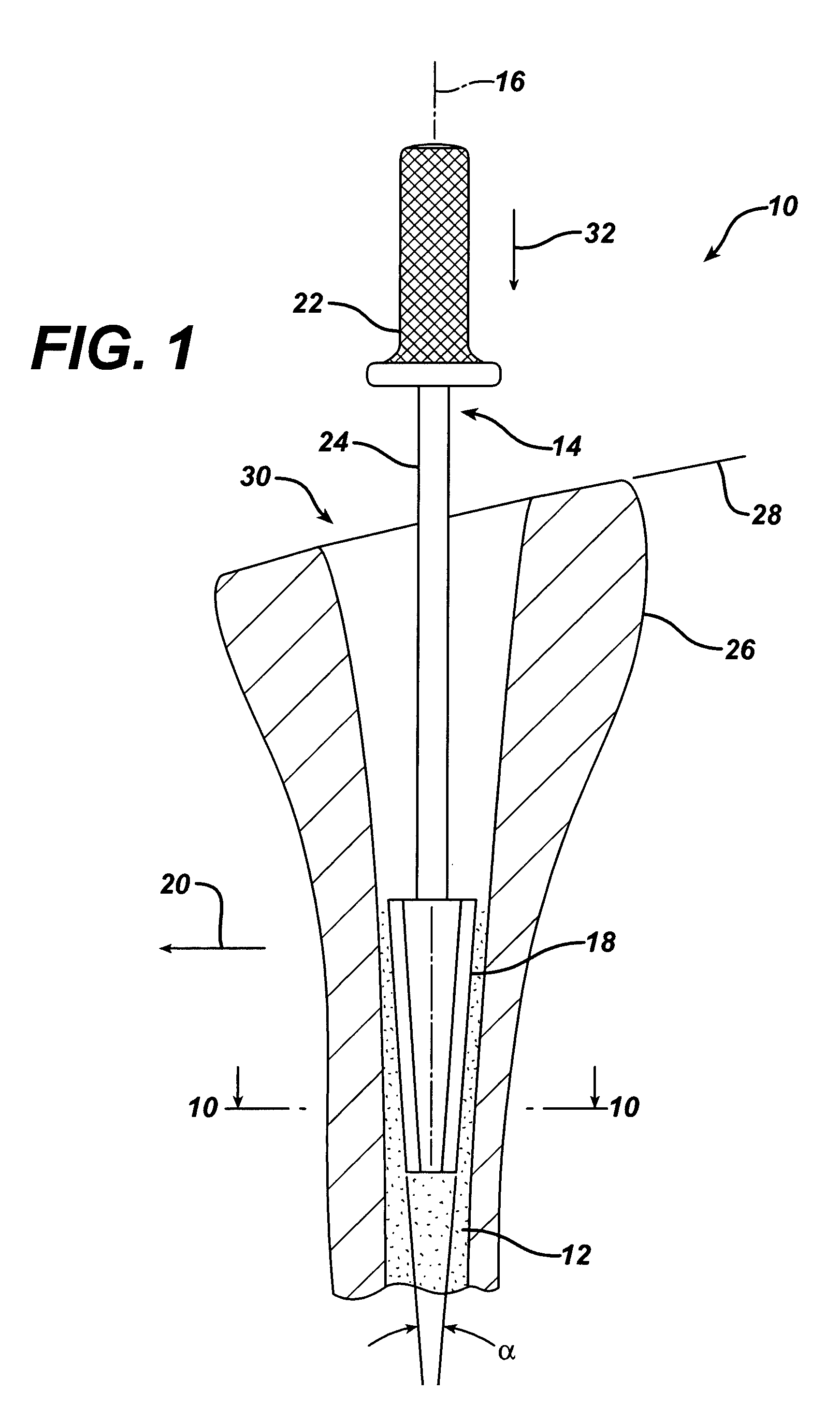

Suture anchor

An improved suture anchor is formed from body tissue. The body tissue is shaped to a desired configuration for the anchor and defines a passage through the anchor. A suture is inserted into the passage in the body tissue of the anchor. The anchor is then positioned in a patient's body with a suture extending into the passage in the anchor. The anchor may be formed of osseous body tissue, hard compact bone, dense connective body tissue, or other body tissue. The body tissue may be dried so that it absorbs fluid and expands upon being inserted into a patient's body.

Owner:BONUTTI SKELETAL INNOVATIONS +1

Suture anchor

Owner:BONUTTI SKELETAL INNOVATIONS

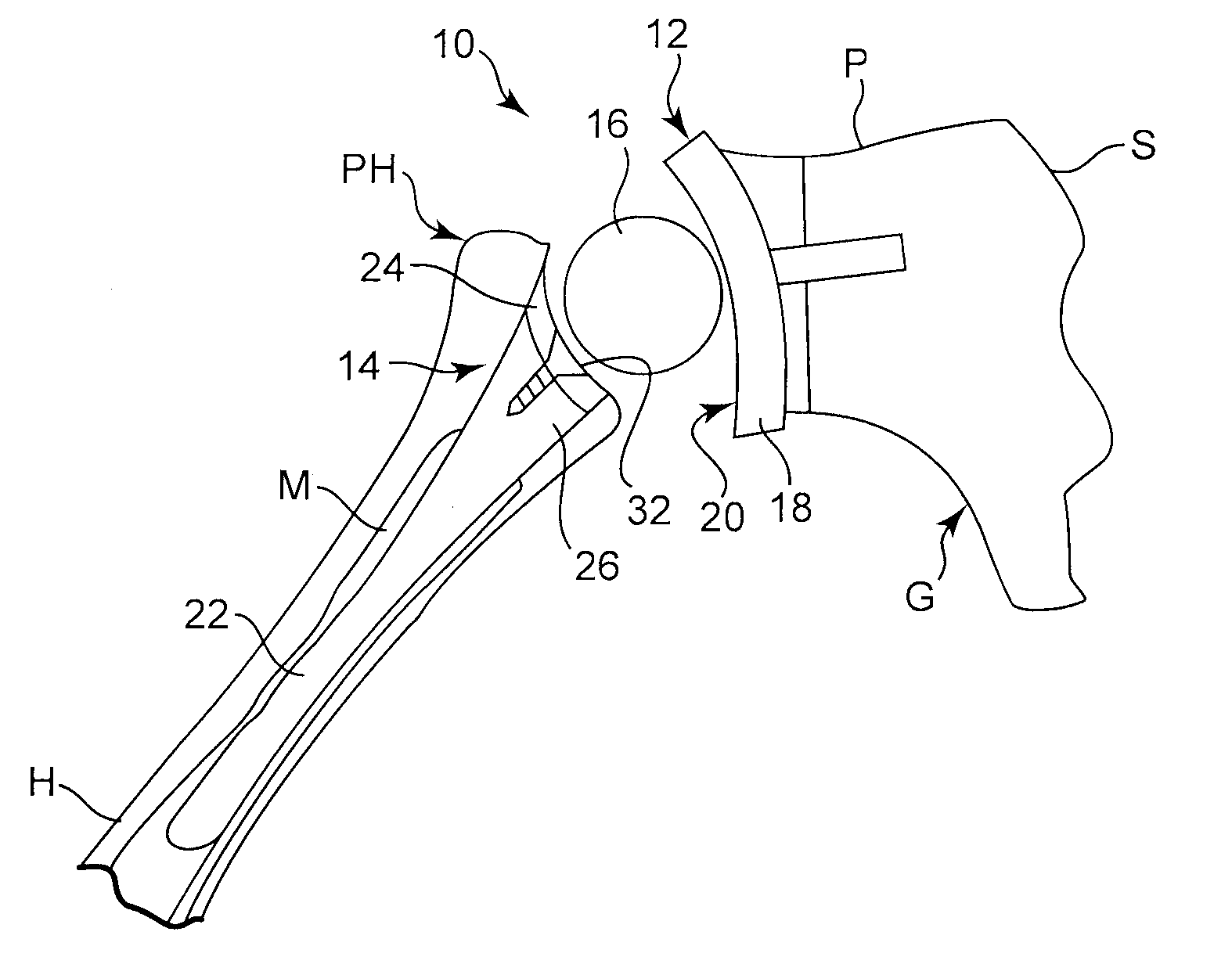

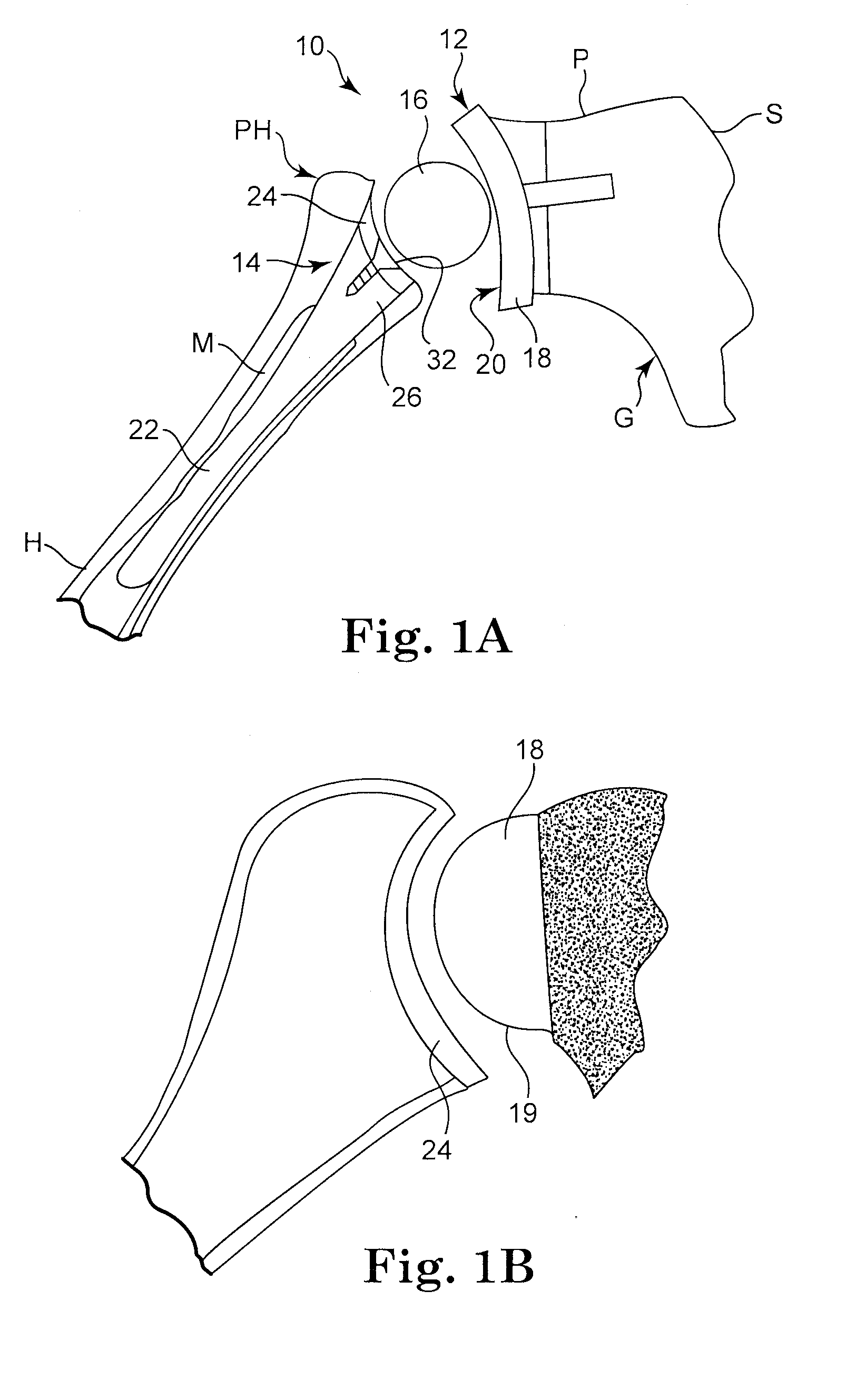

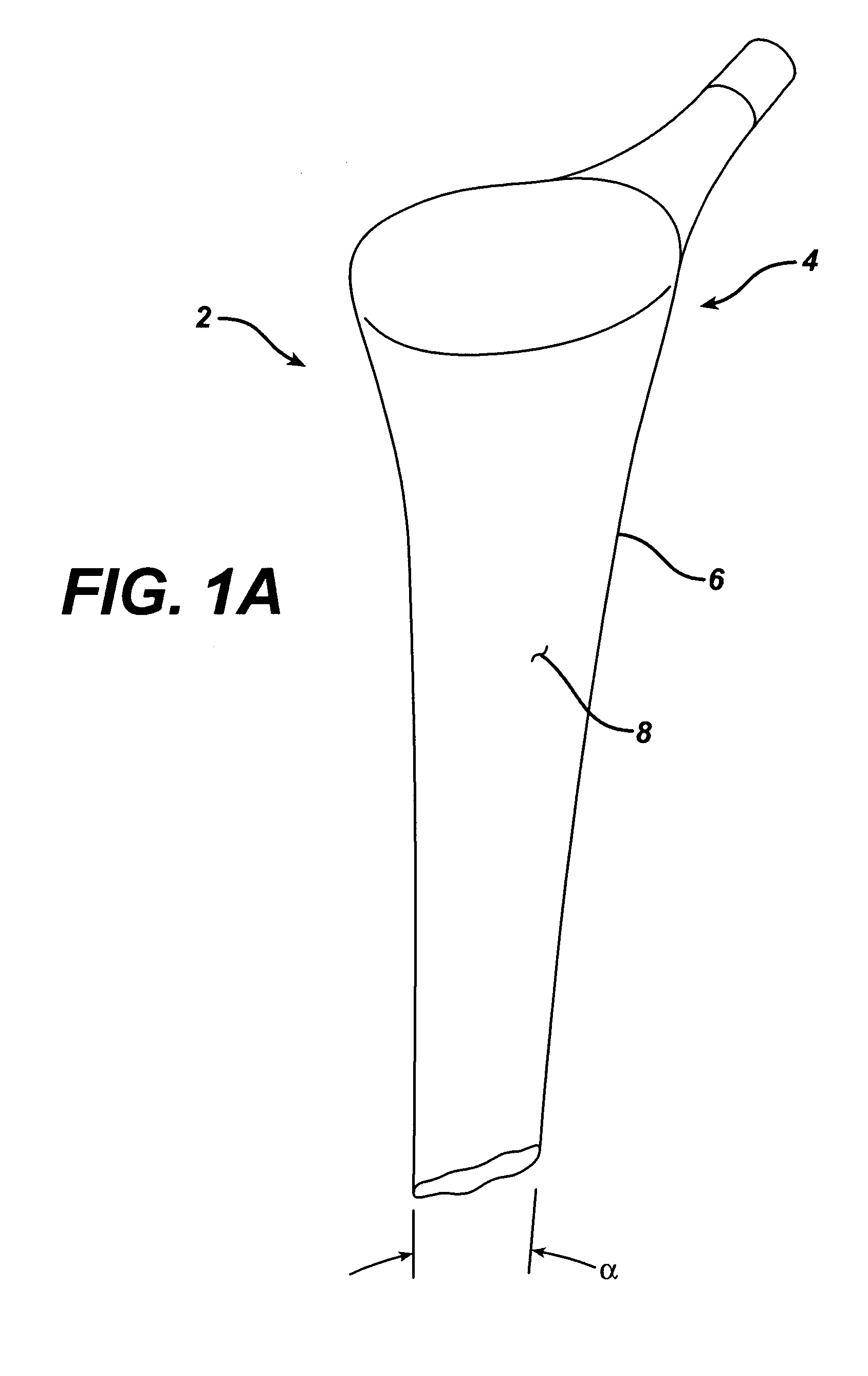

Intra-articular joint replacement

A method of forming a shoulder prosthesis includes forming a concave articular surface into an end portion of a humerus, including compacting bone of the end portion to define the concave articular surface. An implant having a convex articular surface is secured to a glenoid. The concave articular surface of the humerus is articulated with the convex articular surface of the implant.

Owner:TORNIER SA SAINT ISMIER

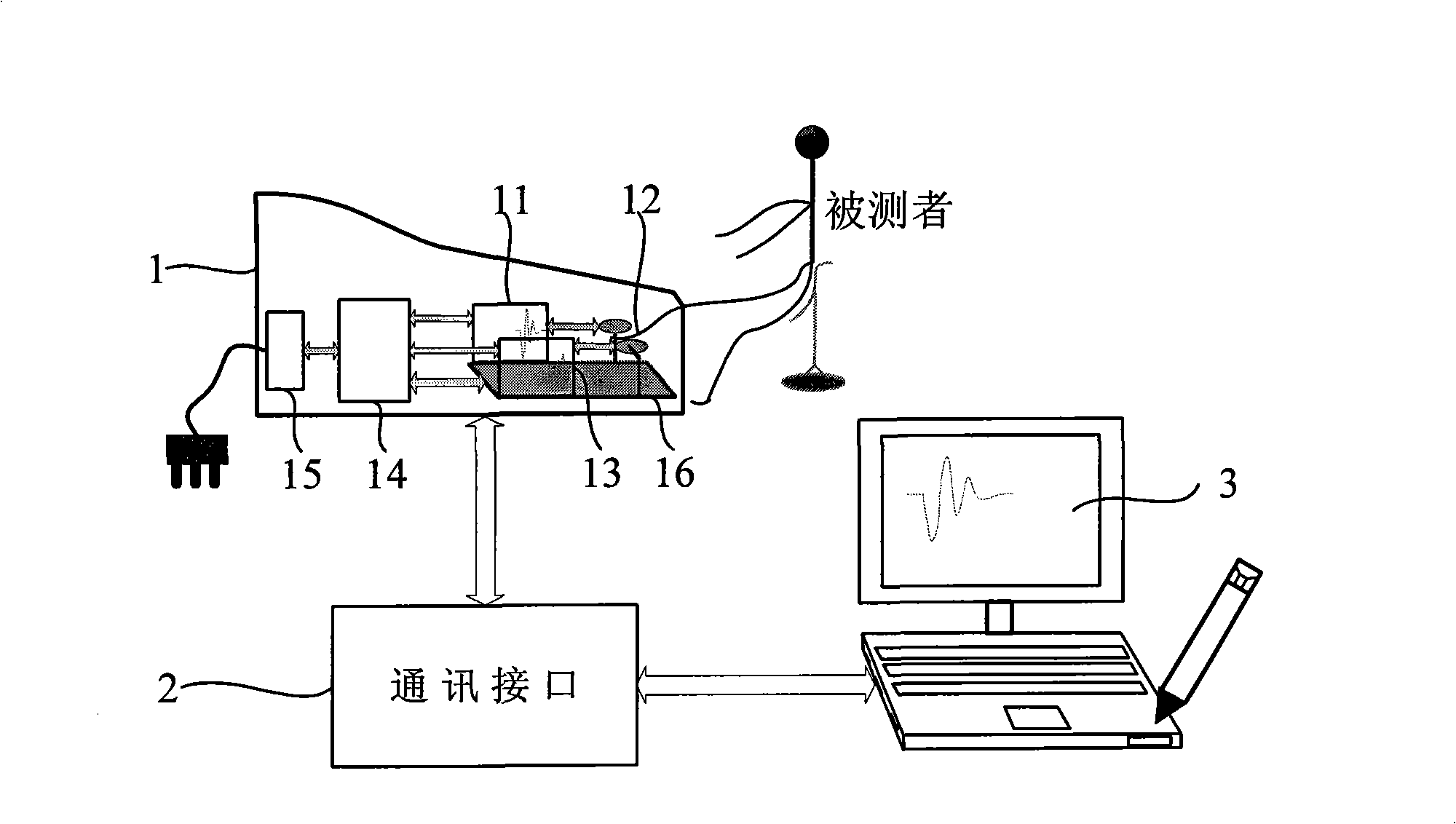

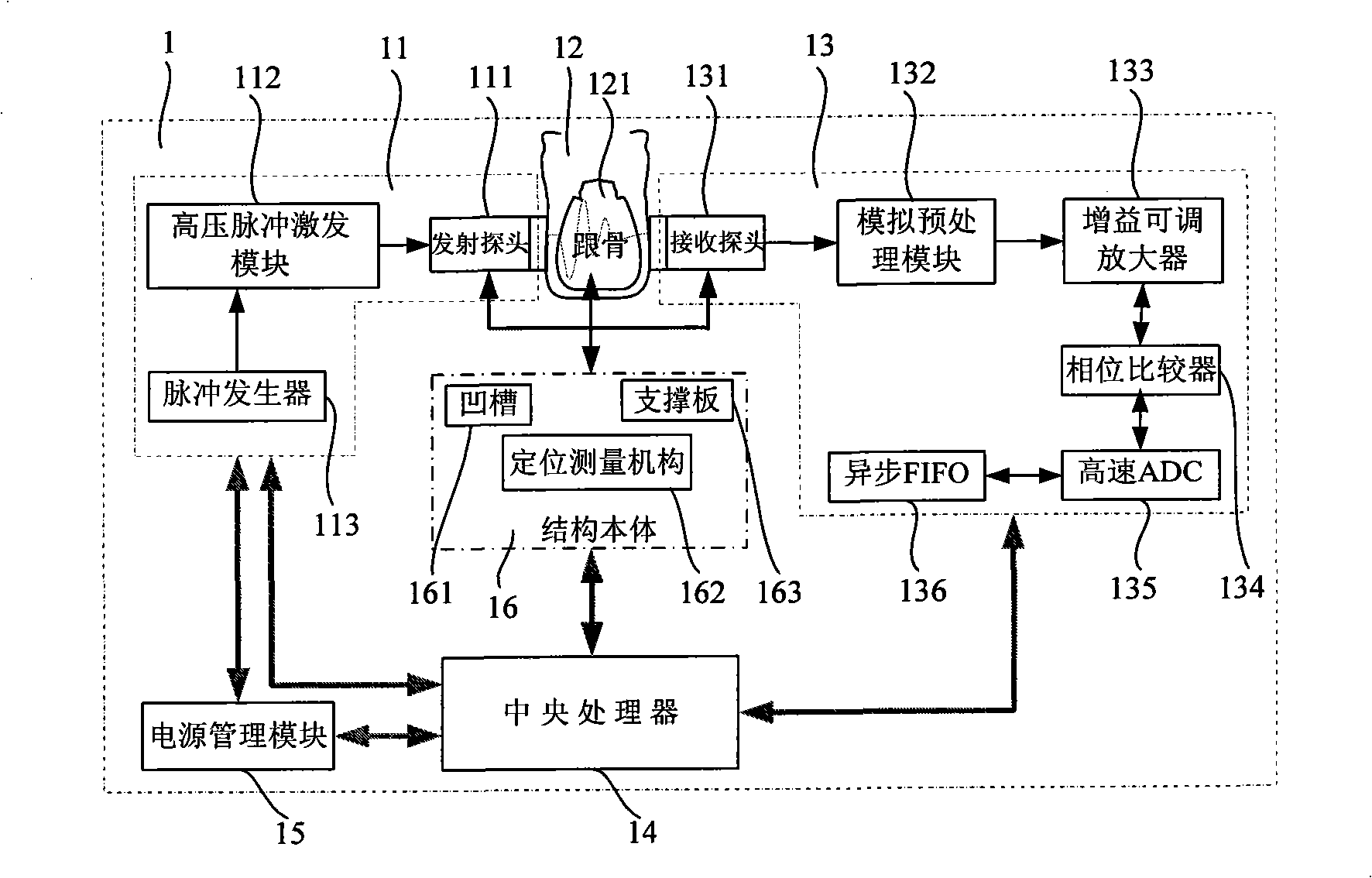

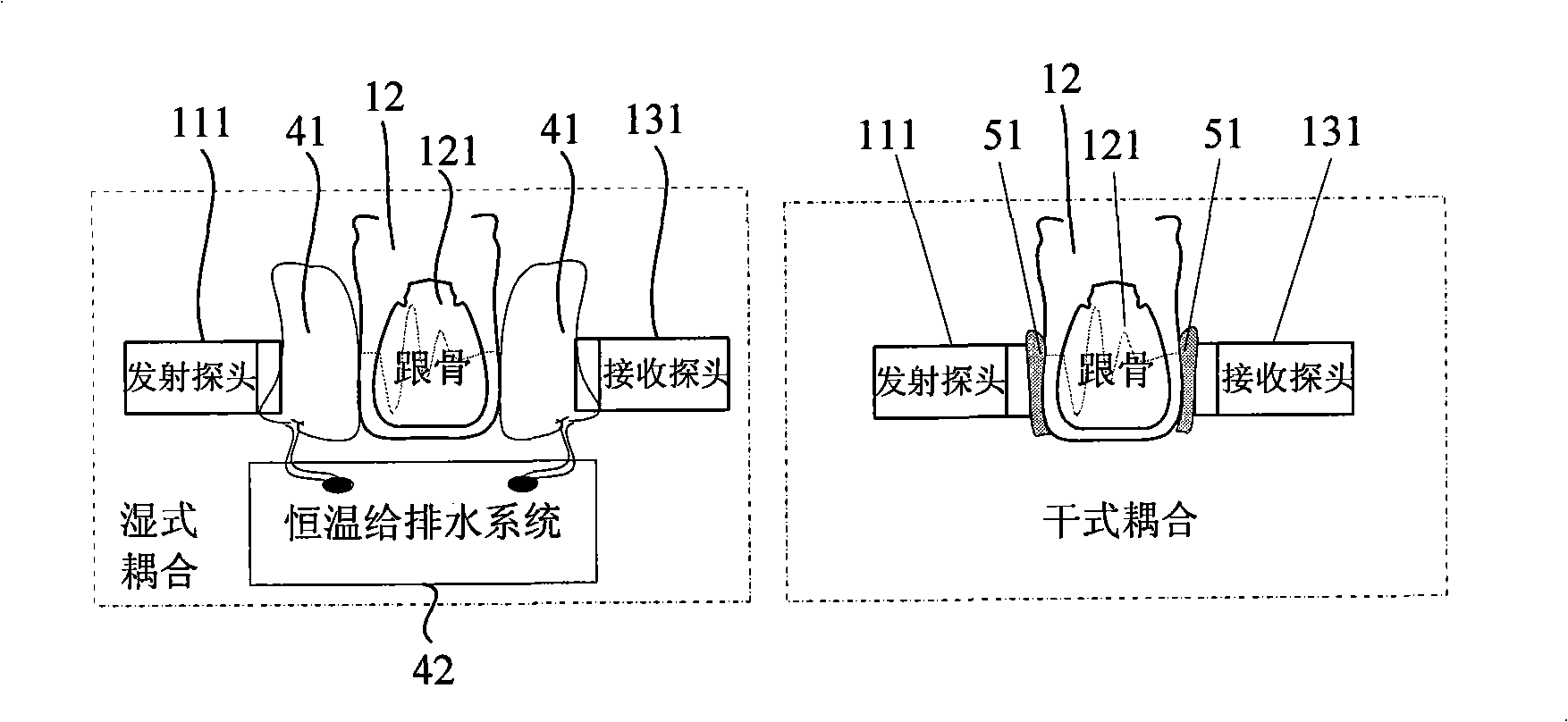

Ultrasonic measurement analytical system for compact bone substance density

ActiveCN101401732APromote disseminationHigh measurement accuracyOrgan movement/changes detectionUltrasonic/sonic/infrasonic dianostic techniquesBone densityHuman–machine interface

The invention discloses an ultrasound bone density measuring and analyzing system. The system comprises an ultrasound parameter measuring apparatus, a communication interface and a human machine interaction device, wherein the ultrasound parameter measuring apparatus comprises transmitting unit consisting of a pulse generator, a high-voltage pulse excitation module and a transmitting probe, an ultrasound receiving unit consisting of a receiving probe, a simulation pretreatment module, a gain adjustable amplifier, a phrase comparator, a high-speed ADC and an asynchronous FIFO, and a central processor, a power supply control module and a structural body. the human machine interaction device controls the ultrasound parameter measuring apparatus through the communication interface to measure the width of a calcaneus of a detected person, the transmission speed of an ultrasound wave in the calcaneus, broadband ultrasonic attenuation to calculate the bone intensity indexes and the bone density, so a medical report can be made according to diagnostic standards of osteoporosis and a special data base can be built for long term use. The system adopts wet or dry coupling and other technologies to improve the precision and accuracy of measure and has the advantages of easy carrying, low cost, no damage caused by radiation and can be use in long term monitoring of bone condition of the detected person.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

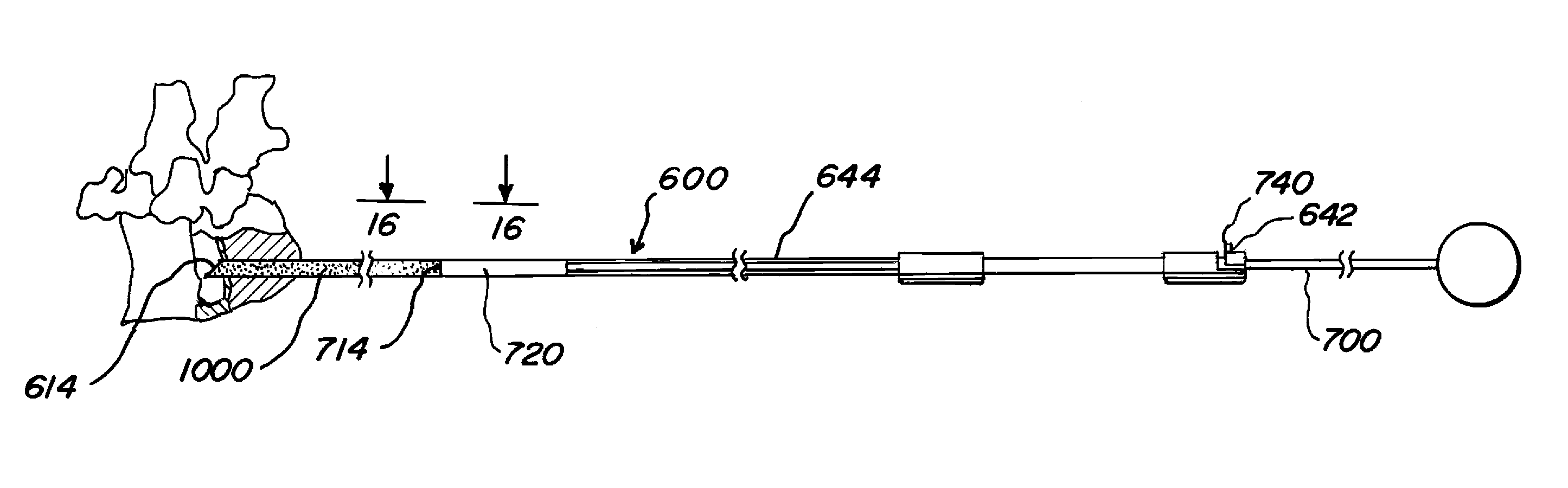

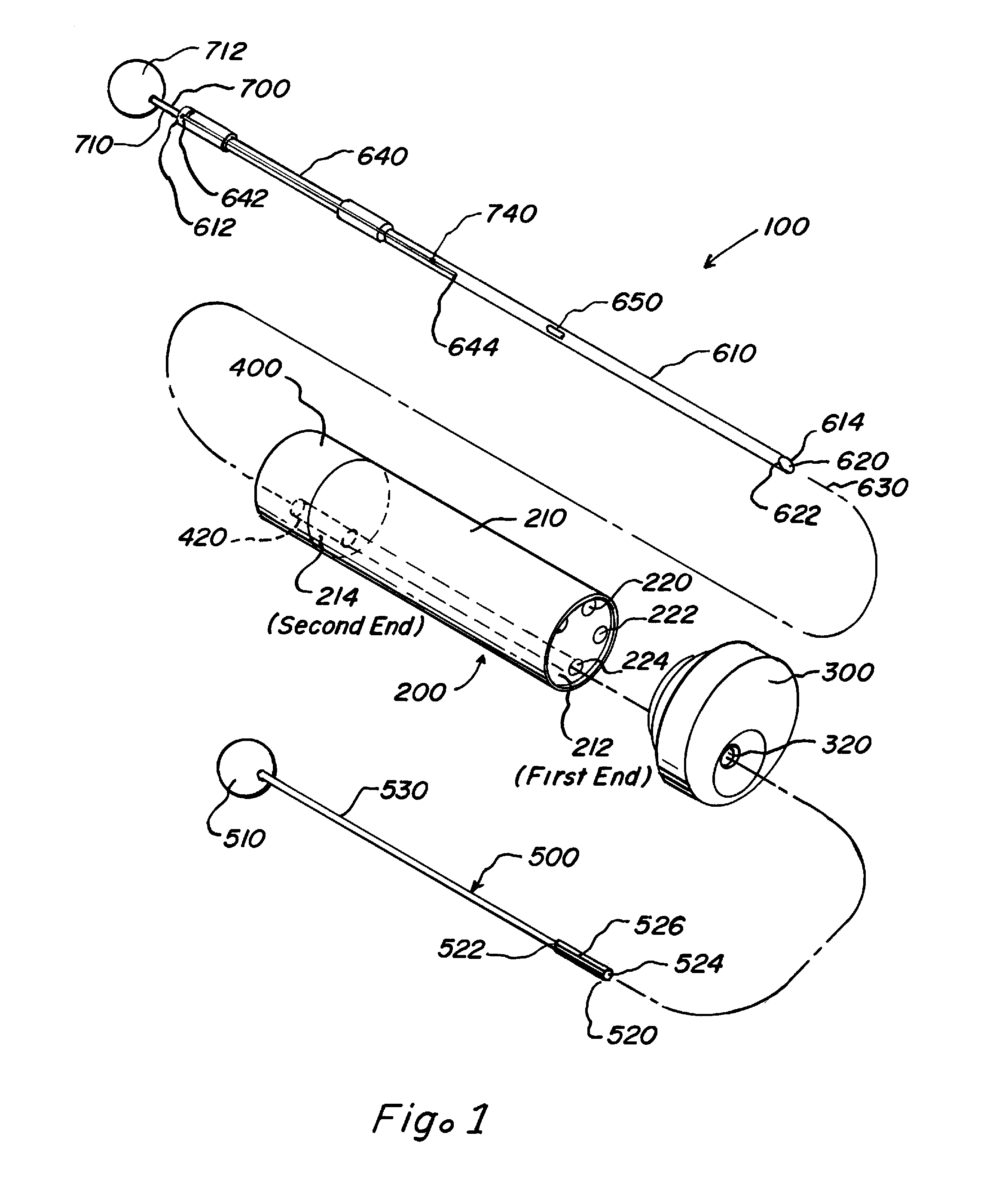

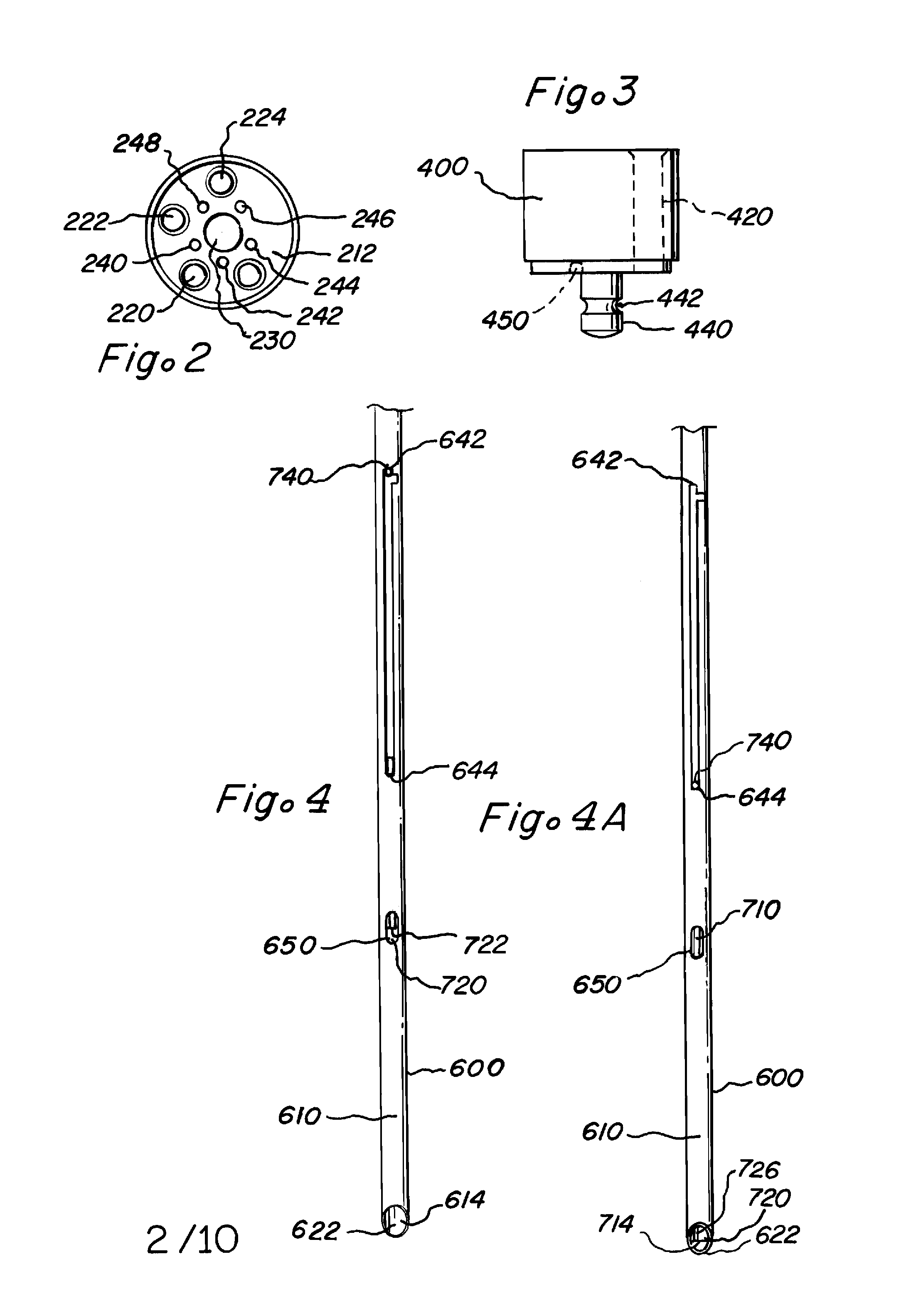

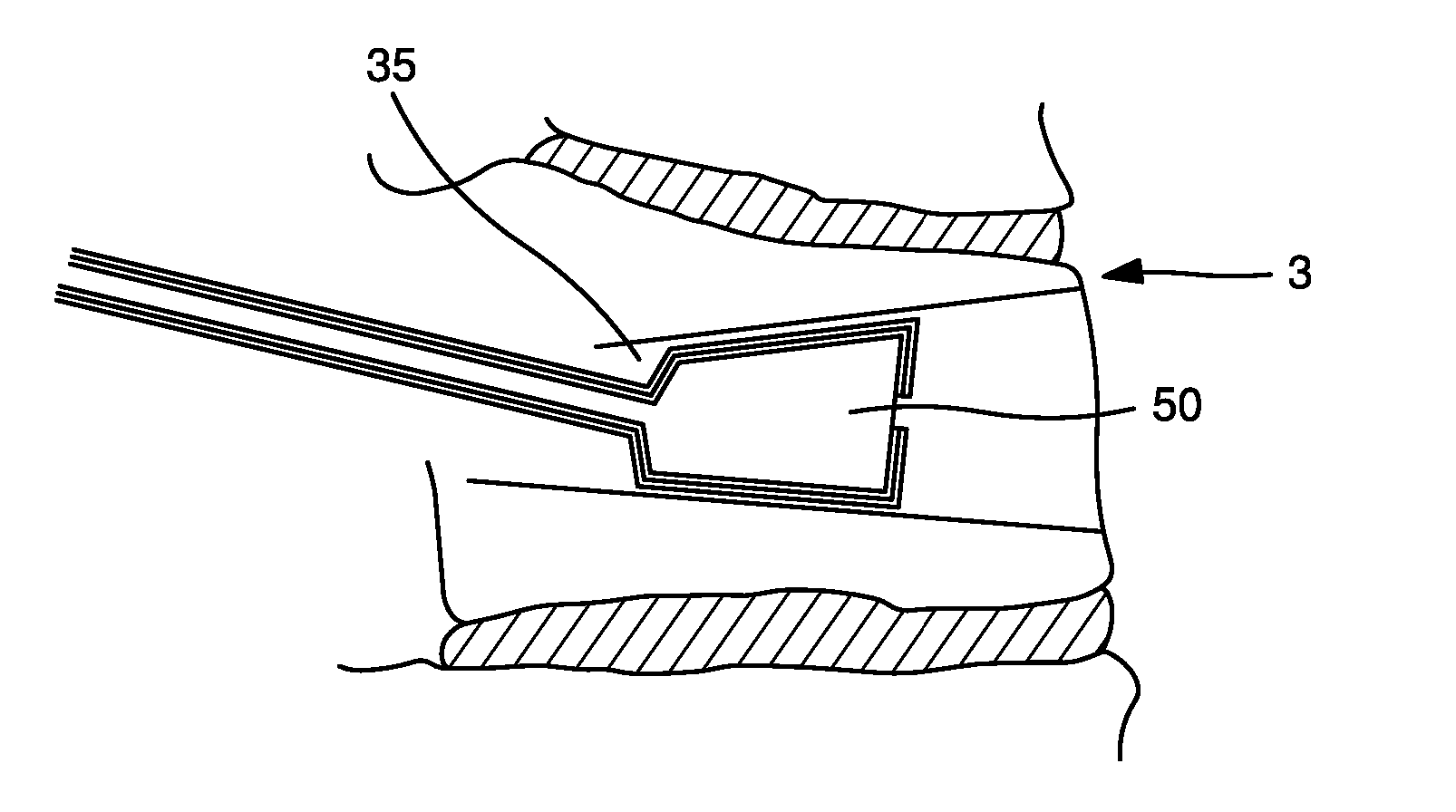

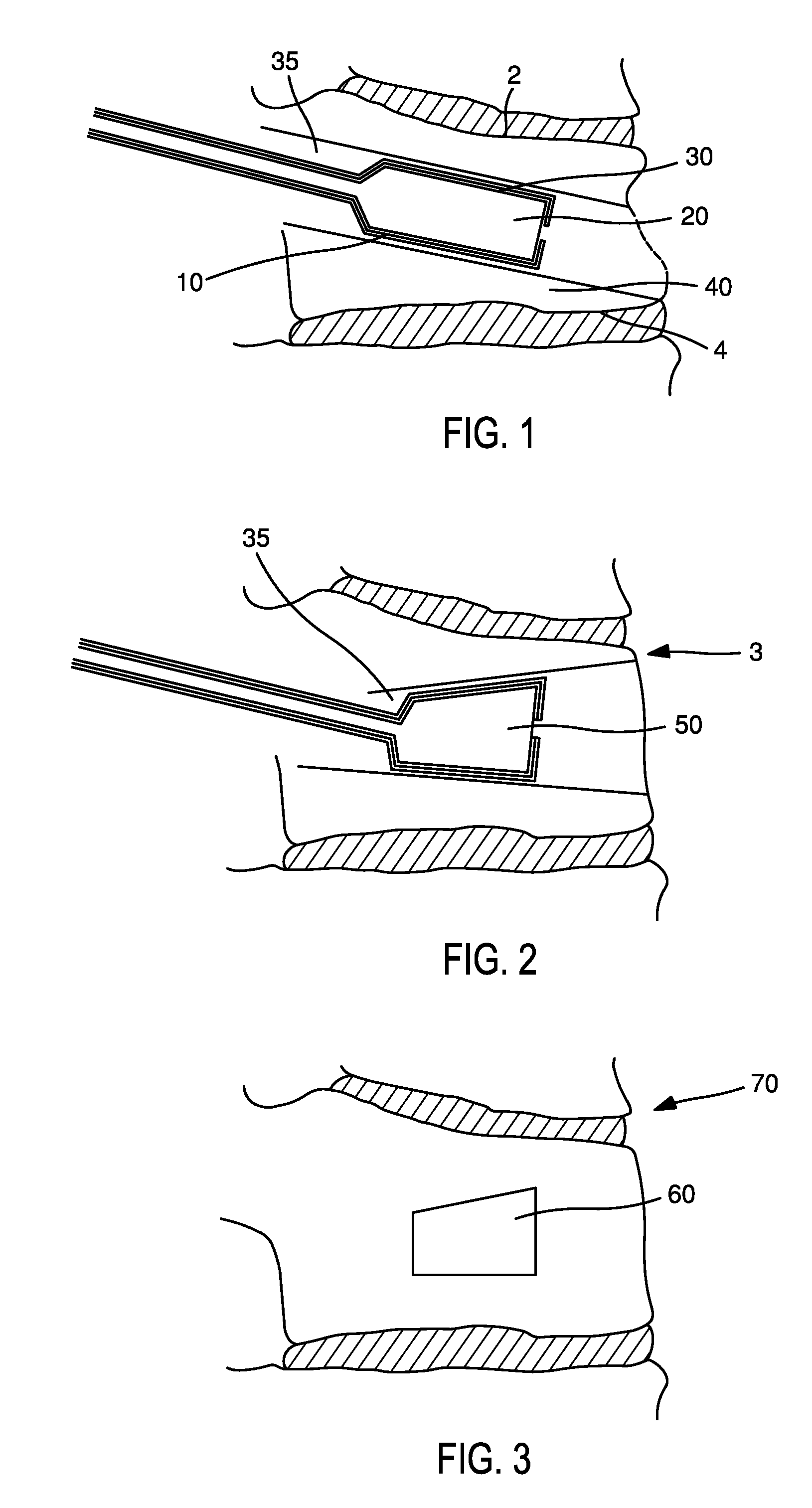

Method and apparatus for bone graft insertion

An apparatus for loading a bone graft material includes a preloading assembly, and a dispenser assembly. A method of dispensing bone graft material includes loading bone graft material into the preloader, compacting the material and transferring the compacted bone graft material into the cannula. The compacted bone graft material is vented to release unwanted or undesirable air, vapor or other gases from the bone graft material. The bone graft material is dispensed after the cannula is placed in a desired or selected position with respect to an intervertebral space.

Owner:BAXANO SURGICAL

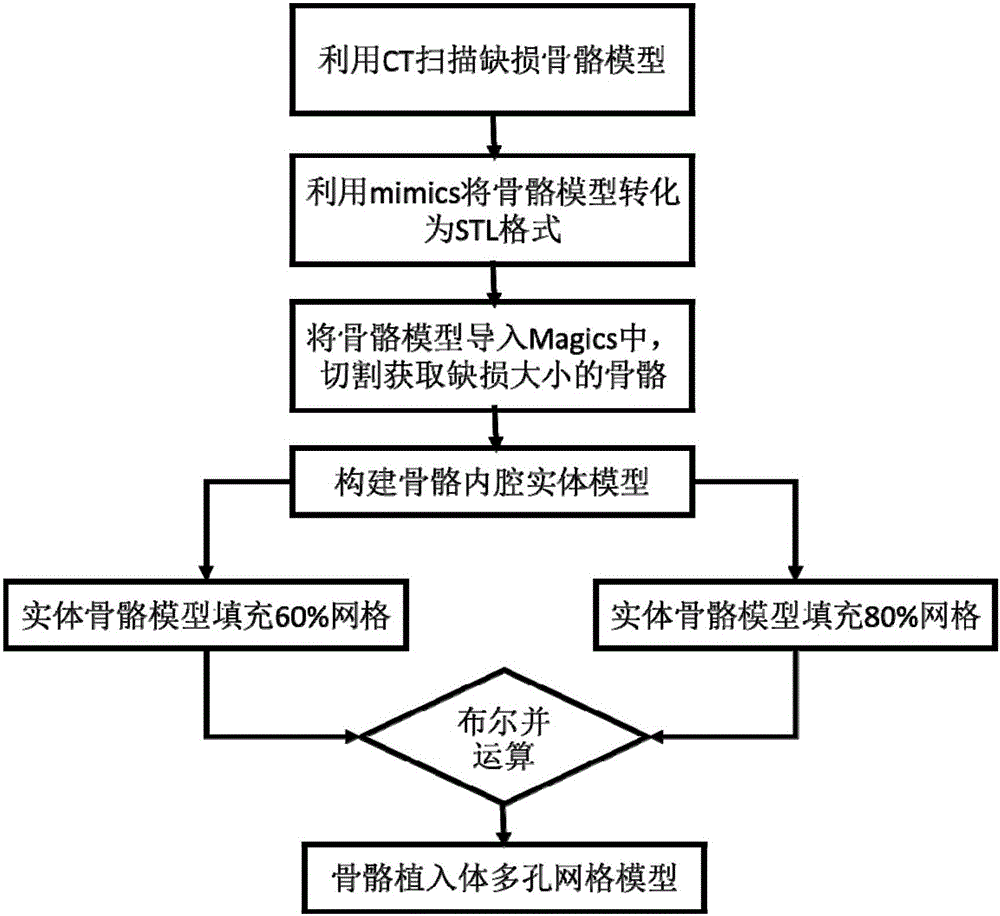

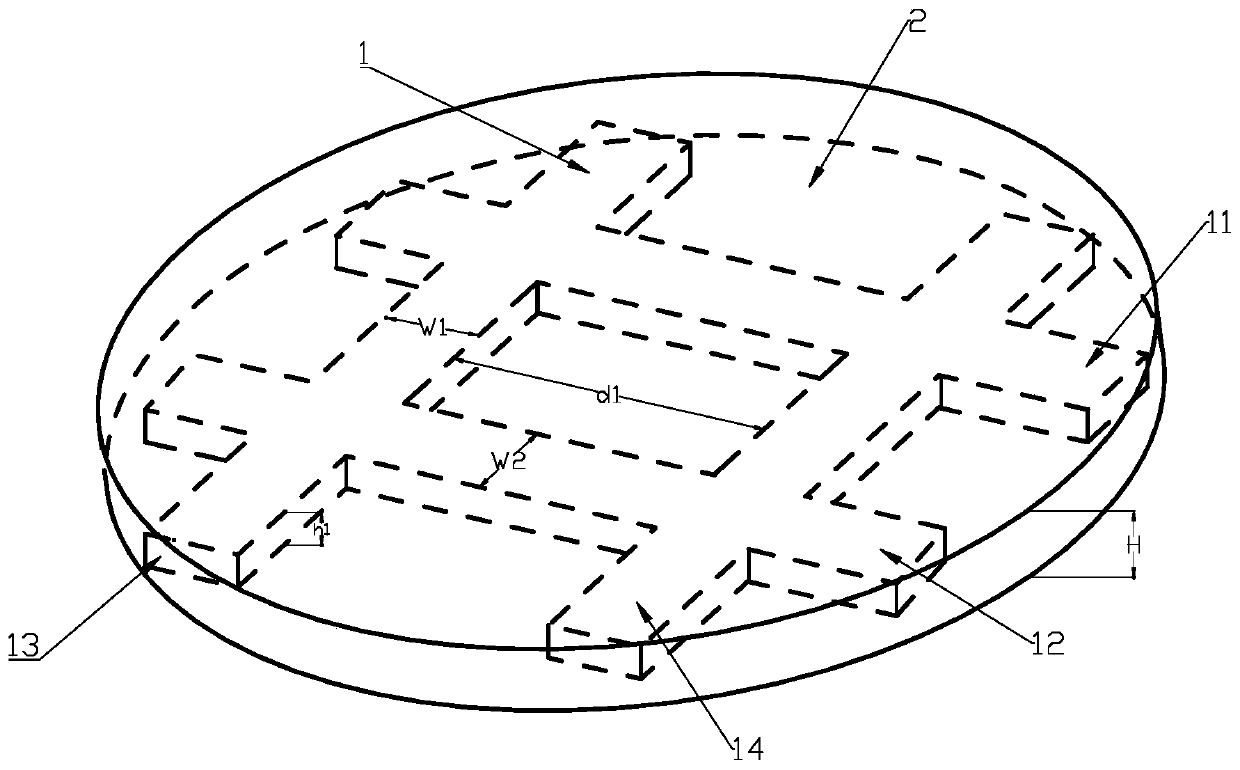

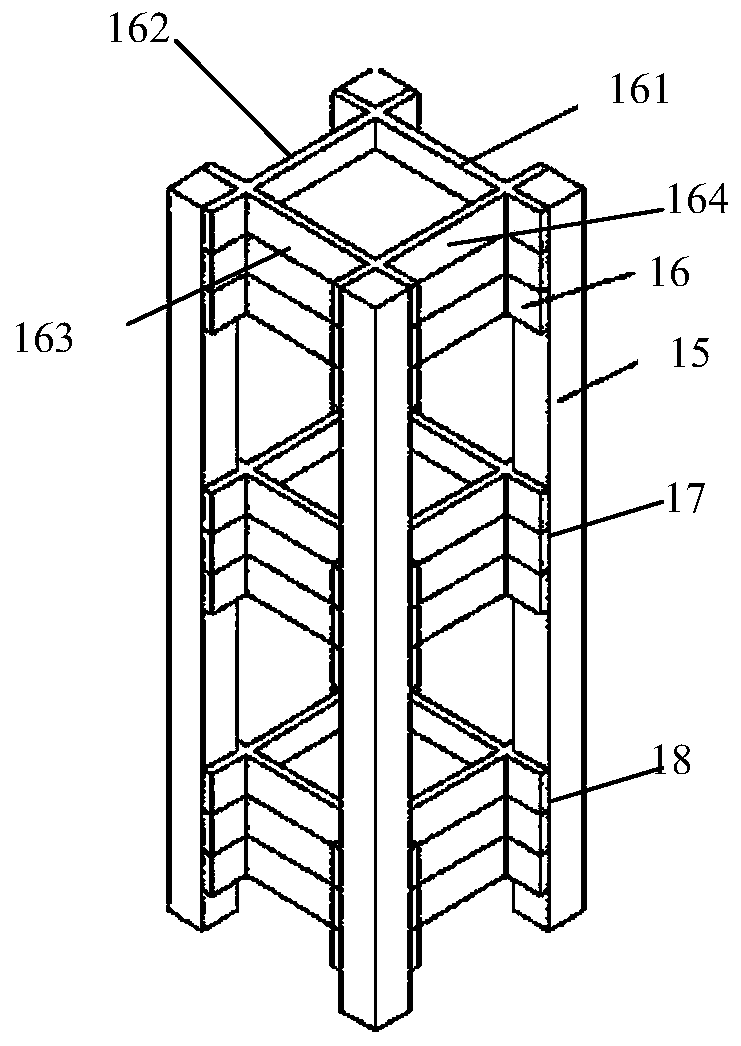

Design method for filling porous grid structure in bone implantation body

ActiveCN105997306AUniversally applicableReduced effective modulus of elasticityBone implantComputed tomographyFilling materials

A design method for an implantation body porous grid structure is characterized in that regional filling of an implantation body with a porous grid array is carried out by Boolean operations. The method is characterized in that a three-dimensional solid model of a defected human body bone is acquired by a medical imaging technology (CT); and according to elastic modulus distribution of the human body bone, namely the elastic modulus of a compact bone is 12-23.3 GPa and the elastic modulus of a cancellous bone is 6-10 GPa, regional grid filling is carried out to the extracted artificial bone model, wherein titanium or medical titanium alloy is taken as the filling material. The method can effectively reduce an equivalent elastic modulus of an implantation body, so that the implantation body can have good mechanical properties in a human body.

Owner:BEIJING UNIV OF TECH

Devices and methods for the treatment of bone fracture

InactiveUS20070156242A1Absent destructive compaction of cancellous boneInternal osteosythesisSpinal implantsVertebral boneBiomedical engineering

A device for treating vertebral bone including a releasably closed, removable filling member which can be placed within a plane separating superior and inferior portions of a vertebral body and oriented to promote its stabilization and realignment upon expansion of the filling member along the plane via injection of filler material, while minimally compacting bone or creating unsupported voids within the interior of the vertebral body.

Owner:CROSSTREES MEDICAL

Preparation method of vinegar-egg powder, compound containing vinegar-egg powder and application thereof

InactiveCN1669478ANo side effectsIncrease bone densityFood preservationSkeletal disorderPhosphopeptideVolumetric Mass Density

The invention provides a preparation method of vinegar-egg powder, compound containing vinegar-egg powder and application, wherein the preparation comprises steeping eggs into fruit vinegar made of orange or haw thorn, then carrying out mincing, filter-pressing and spray drying. The obtained composition comprises vinegar egg powder, calcium carbonate, epimeddium, drynaria, Siberian solomonseal rhizome, Chinese angelica root, notoginseng, casein phosphopeptide. The composition can be applied to the preparation for health food for increasing compact bone substance density, prevention and cure of osteoporosis, alleviating fatigue and enhancing immunity.

Owner:HANGZHOU XINFU TECH CO LTD

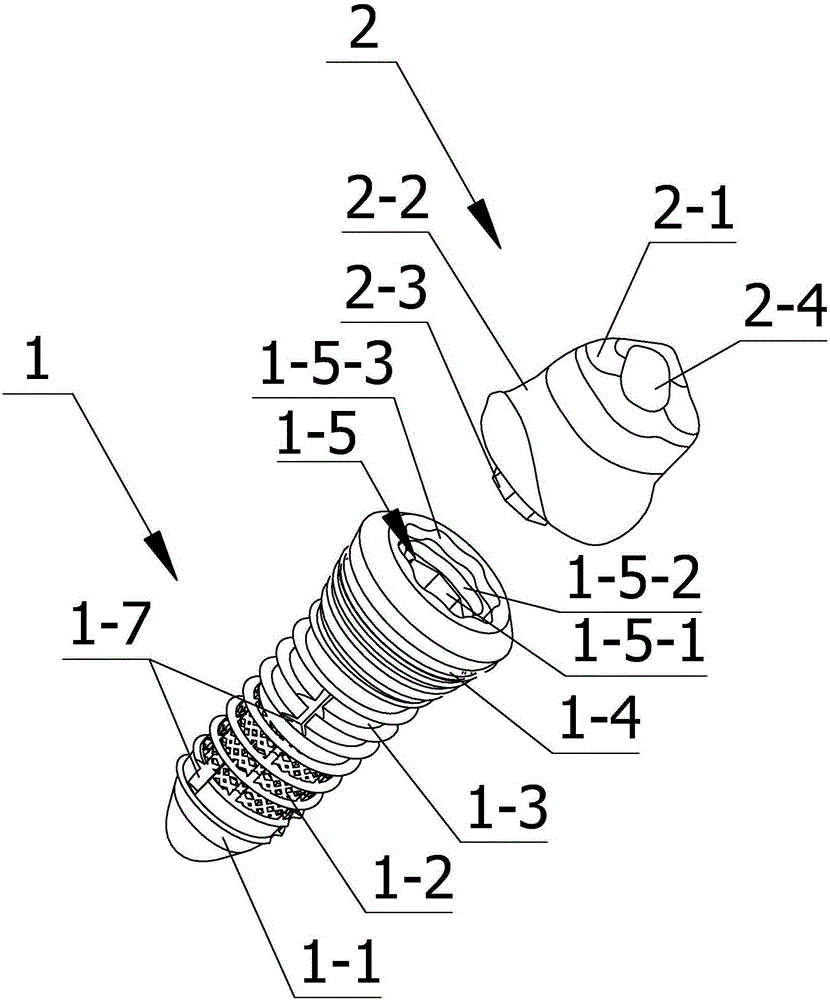

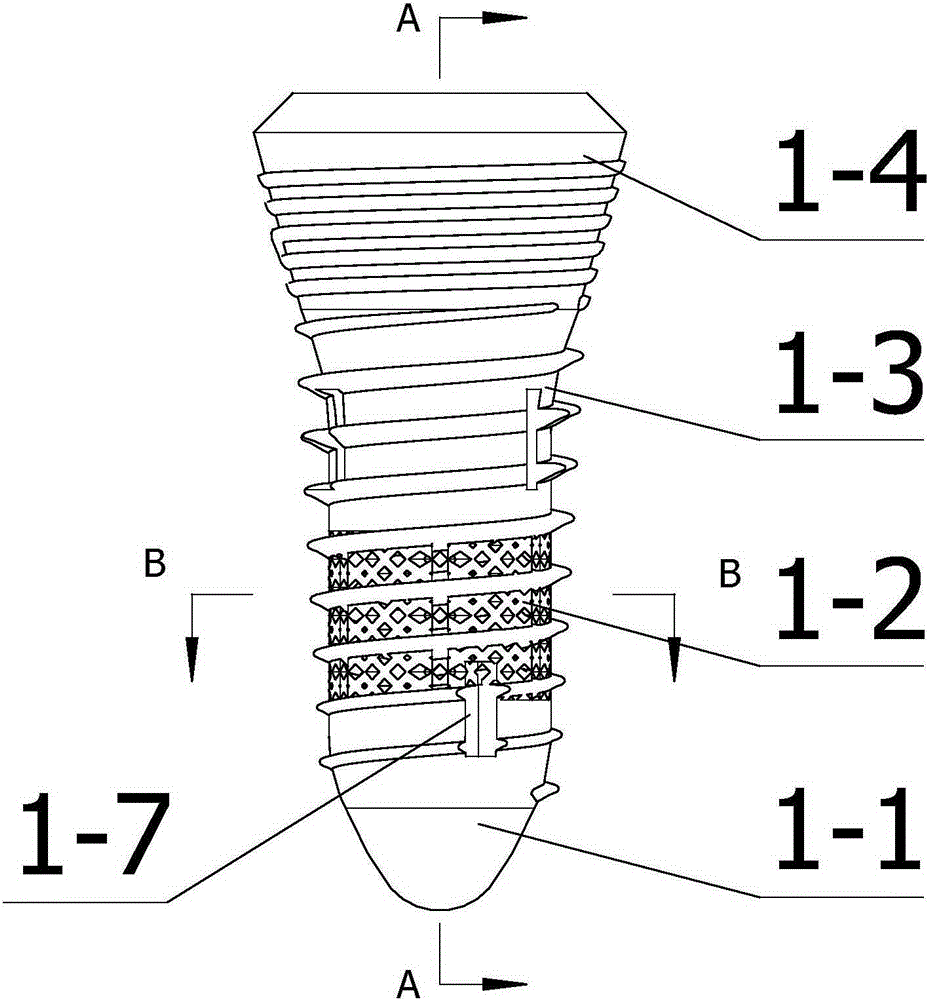

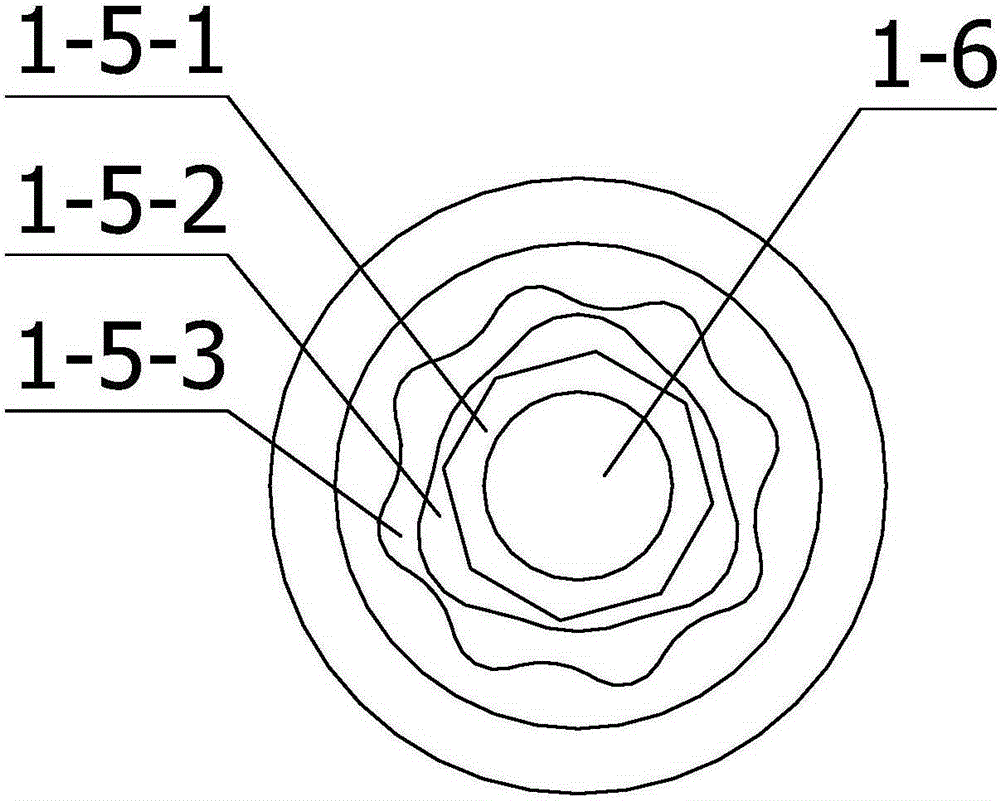

Multi-section implant assembly and manufacturing method thereof

The invention relates to a multi-section implant assembly and a manufacturing method thereof. The implant assembly comprises an implant, an individual abutment and a fixed bolt, wherein the implant comprises an implanted section I, an implanted section II, an implanted section III and an implant trans-gingival section; the implanted section II is a porous section; a threaded counter bore is arranged inside the implant body; an abutment interface is arranged at the upper end of the implant; the individual abutment comprises a crown connection section, an abutment trans-gingival section and an implant connection section; a stepped hole is additionally arranged in the middle of the individual abutment; and the threaded end of the fixed bolt is in threaded connection to the threaded counter bore. The implant assembly can be customized according to the actual modulus of alveolar bone of a patient; by virtue of the structure of the porous section, the contact area between the implant and compact bone is improved and a fitting property of the implant to the compact bone is improved, so that the compact bone is continuously stimulated, a problem of loosening after firmware is installed is solved and binding force of the implanted implant body with the alveolar bone is improved, and a bone infusion effect is good. The manufacturing method is high in forming speed and short in manufacturing cycle, and the manufacturing method is capable of meeting actual demands of various patients.

Owner:FUJIAN CTRUE MATERIALS TECH

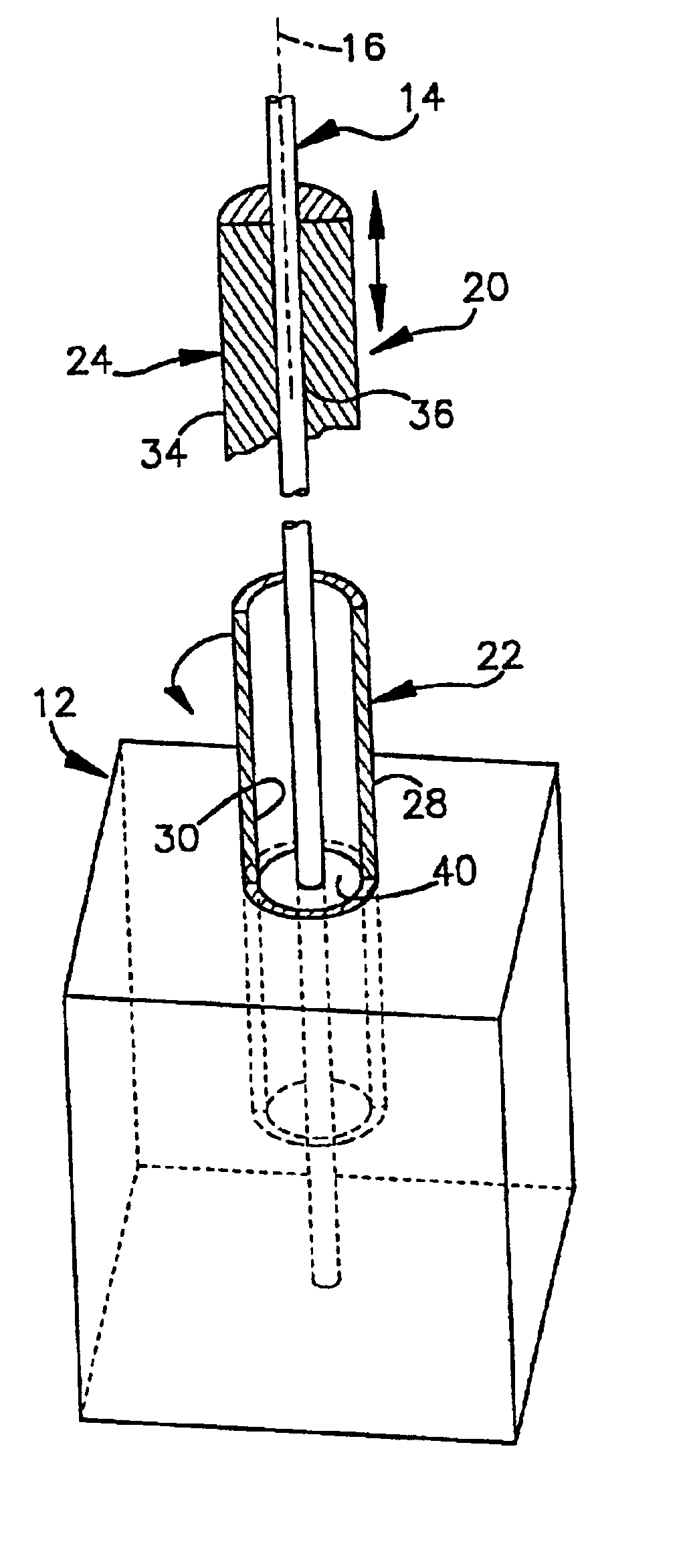

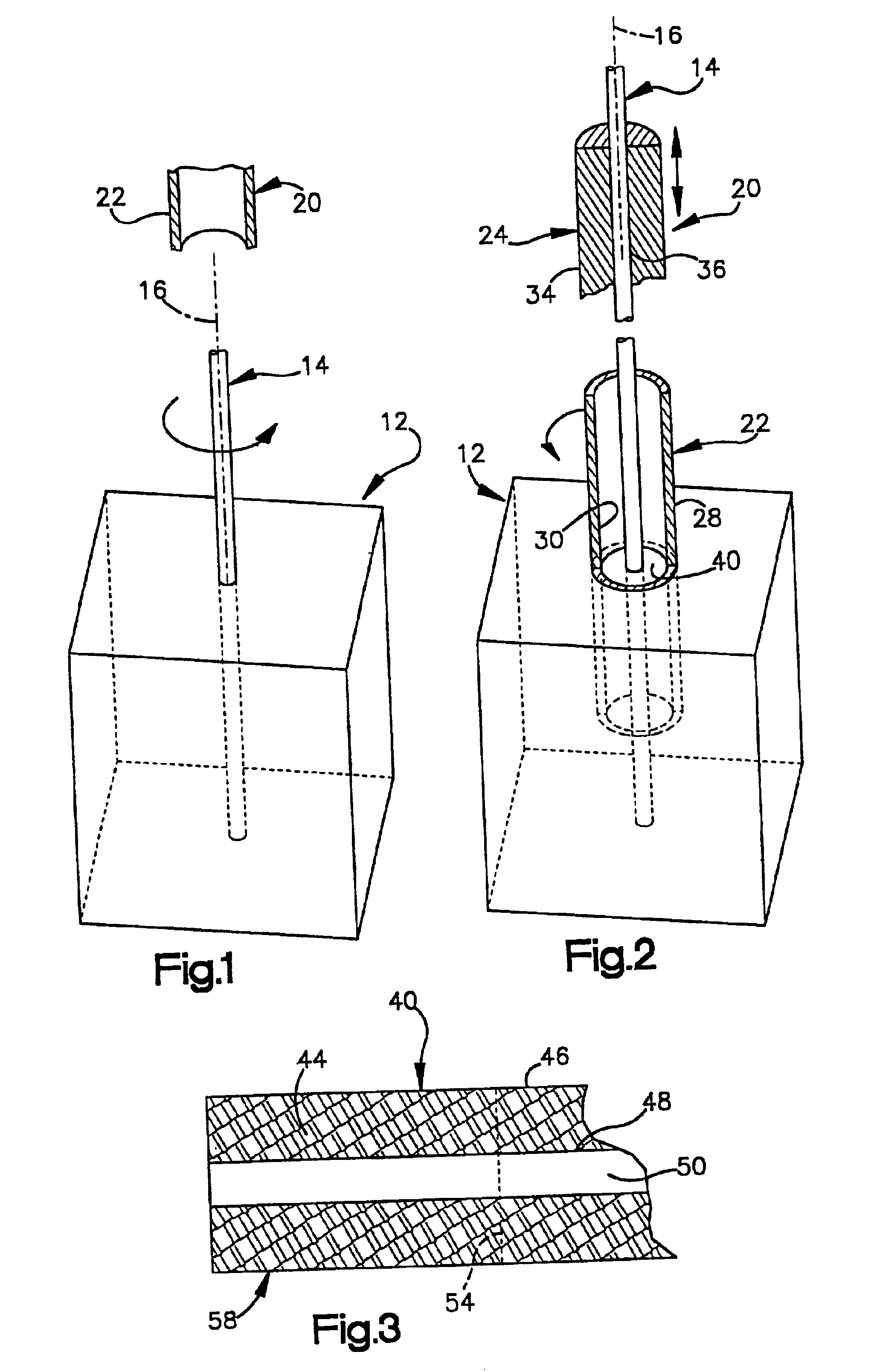

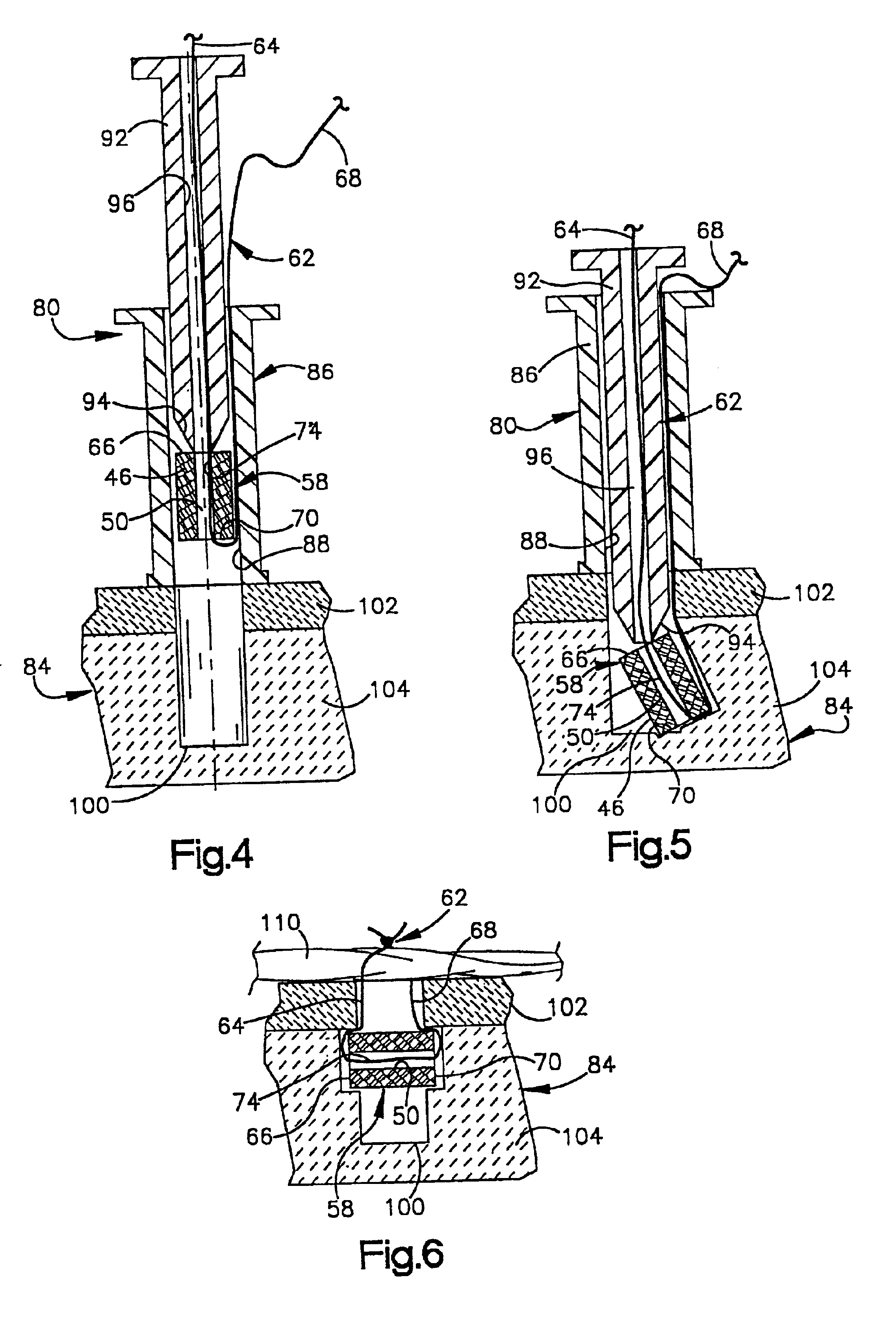

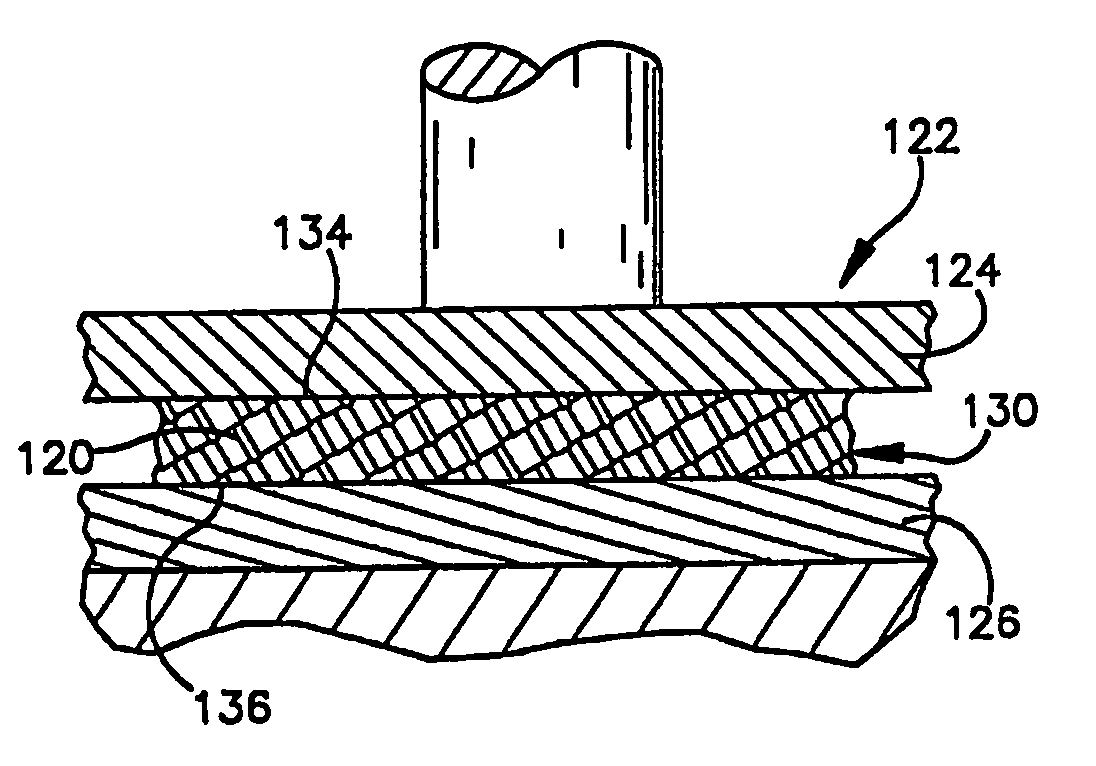

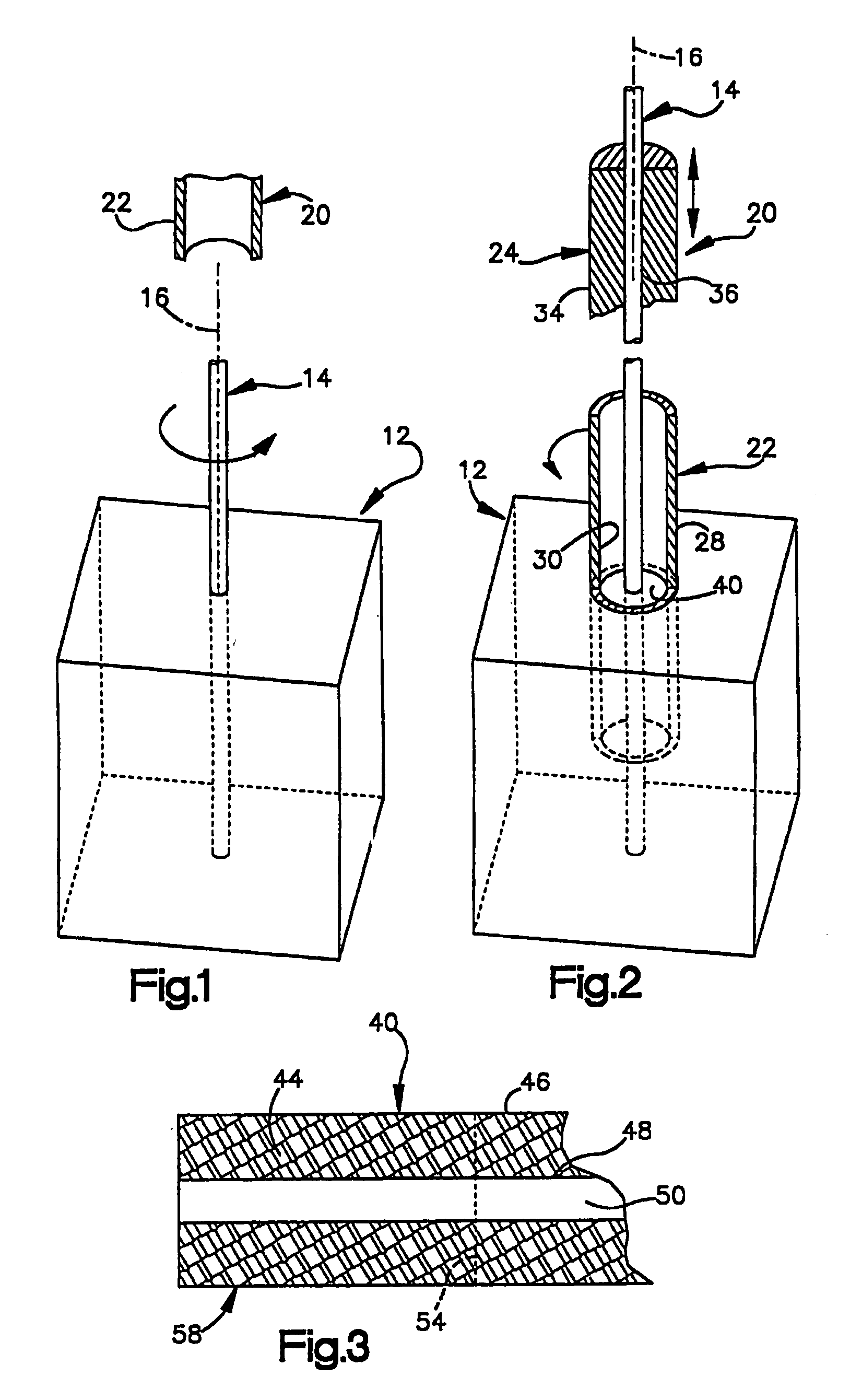

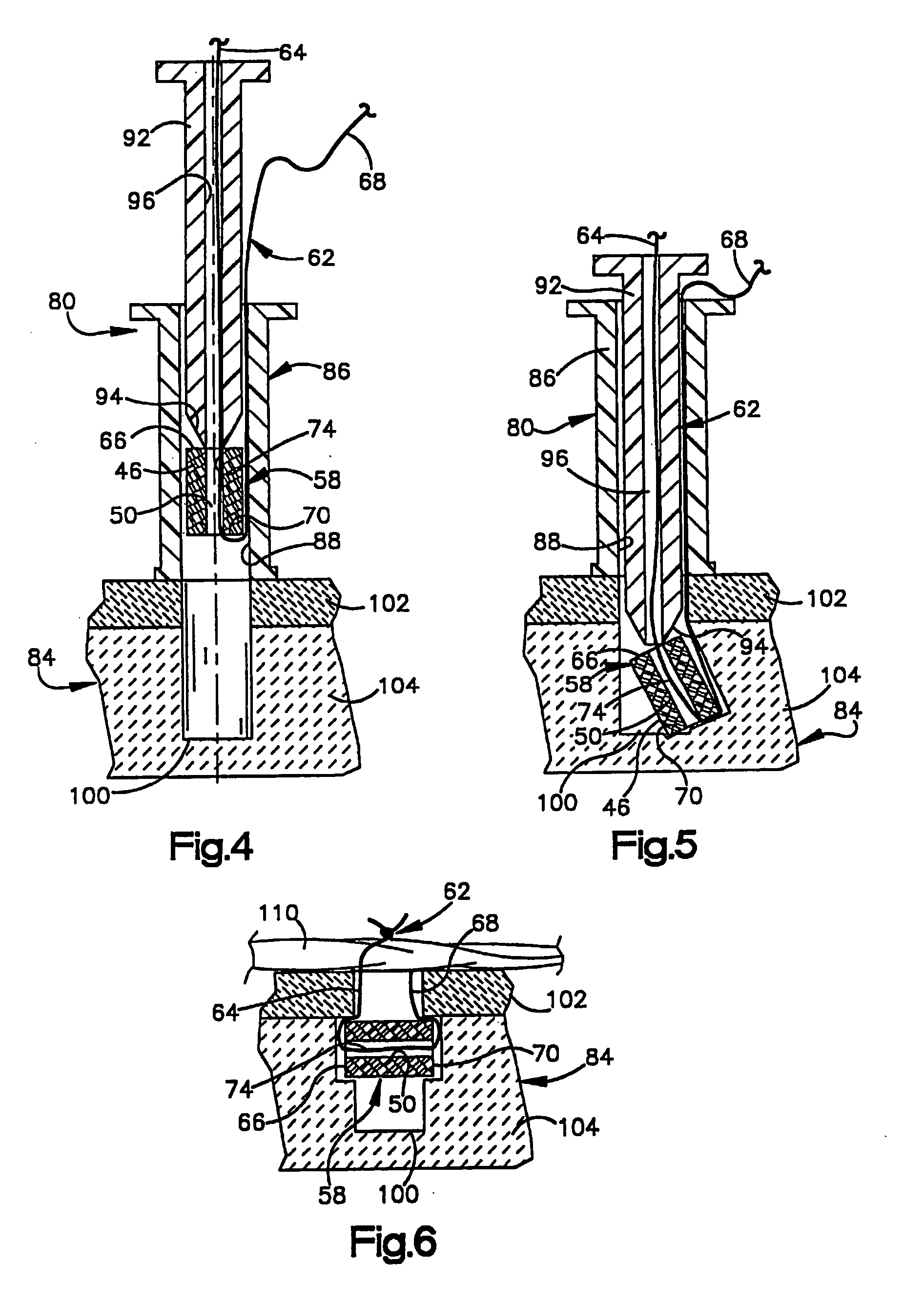

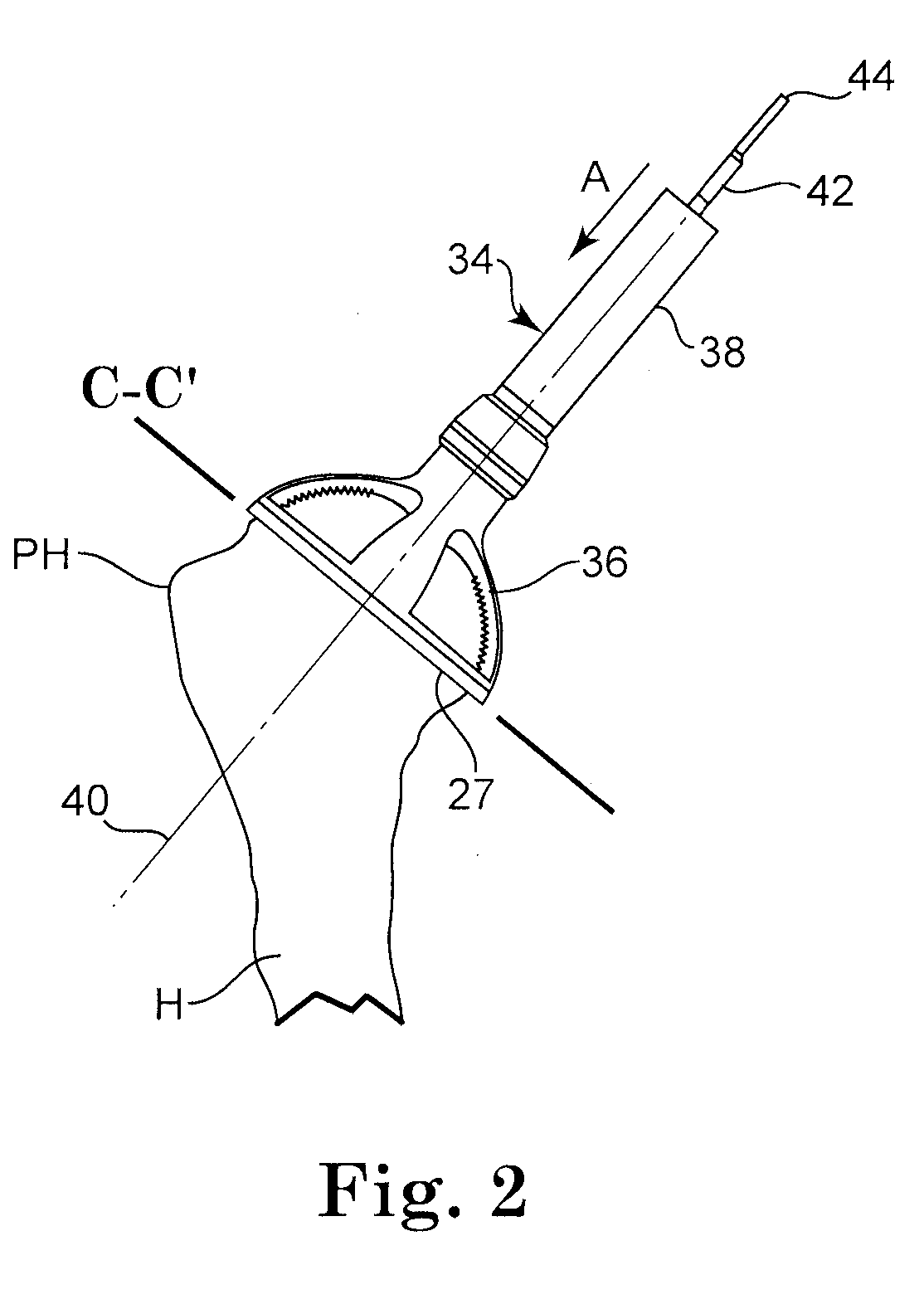

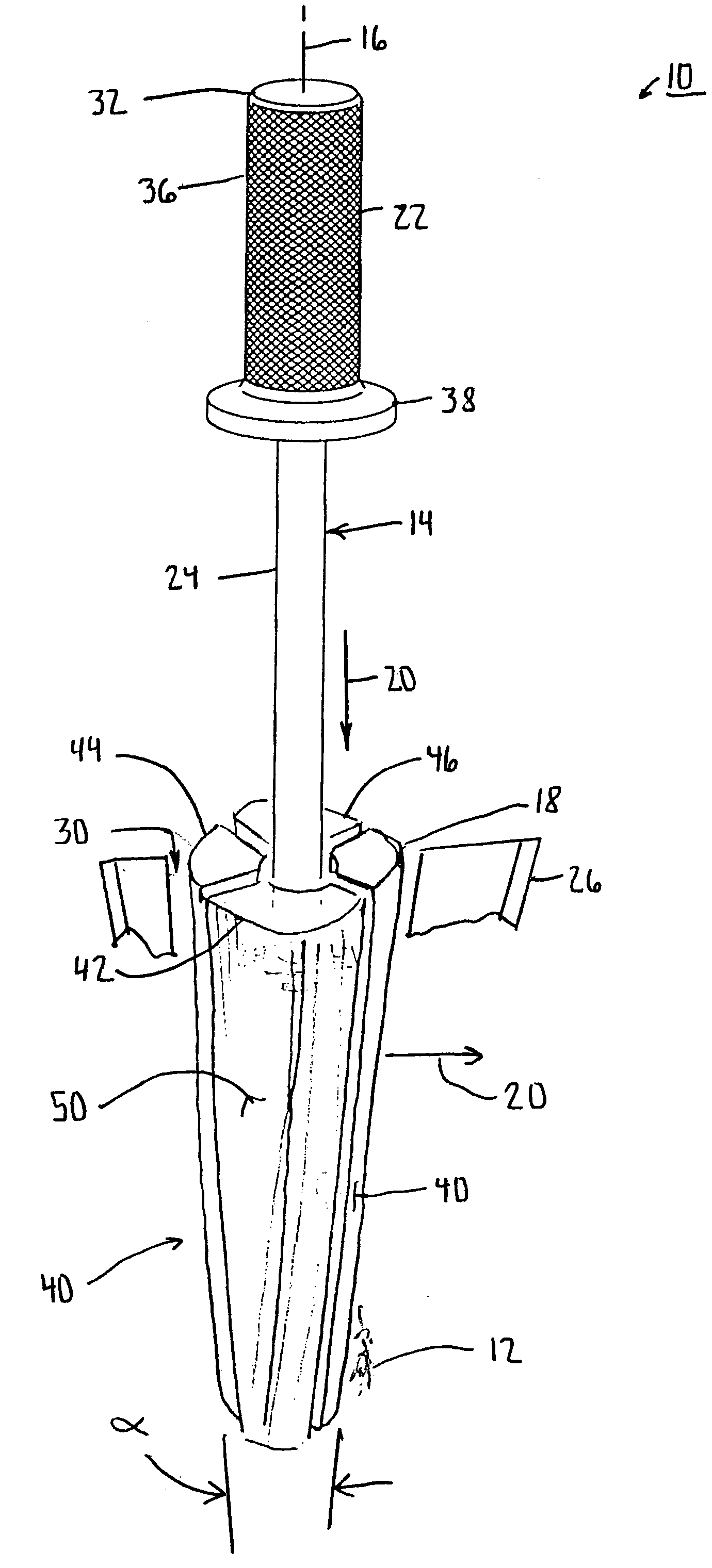

Radial impaction bone tamp and associated method

ActiveUS20050070898A1Improve compactionGreat radial impaction forceJoint implantsFemoral headsBiomedical engineeringBone material

An instrument for compacting bone material is provided. The instrument includes a first component defining a longitudinal axis of the first component and a second component. The second component is moveably associated with the first component. The second component is moveable at least partially in a radial direction outwardly from the longitudinal axis of the first component.

Owner:DEPUY ORTHOPAEDICS INC +1

Radial impaction bone tamp and associated method

ActiveUS7799029B2Improve compactionImprove impactJoint implantsFemoral headsBiomedical engineeringBone material

An instrument for compacting bone material is provided. The instrument includes a first component defining a longitudinal axis of the first component and a second component. The second component is moveably associated with the first component. The second component is moveable at least partially in a radial direction outwardly from the longitudinal axis of the first component.

Owner:DEPUY ORTHOPAEDICS INC +1

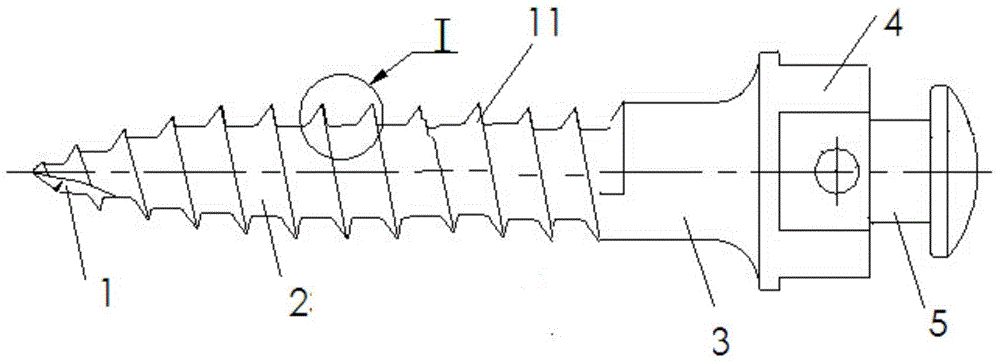

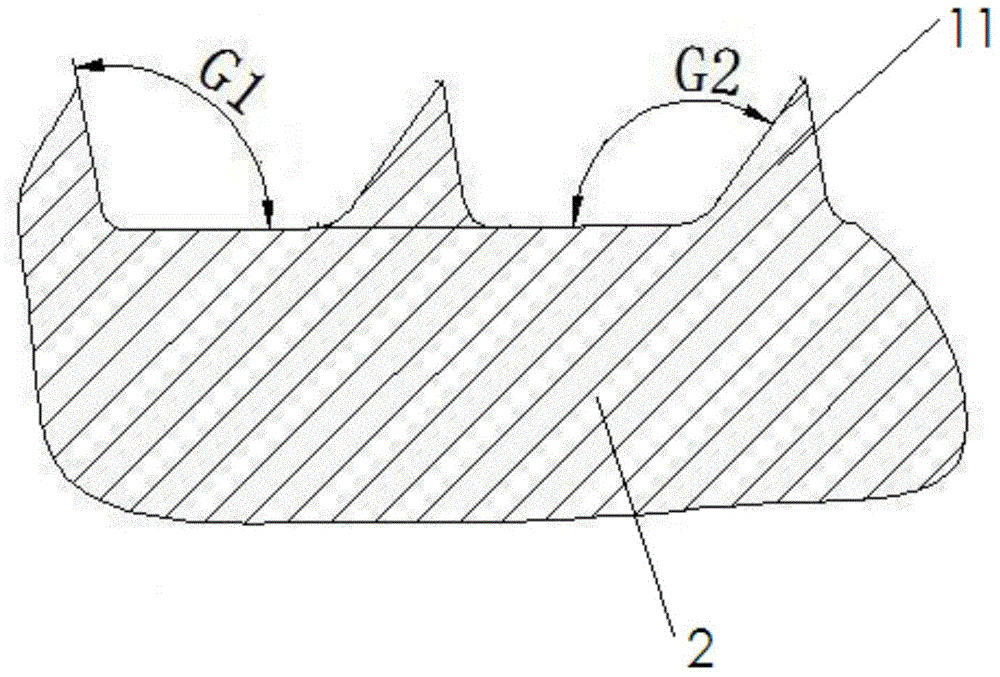

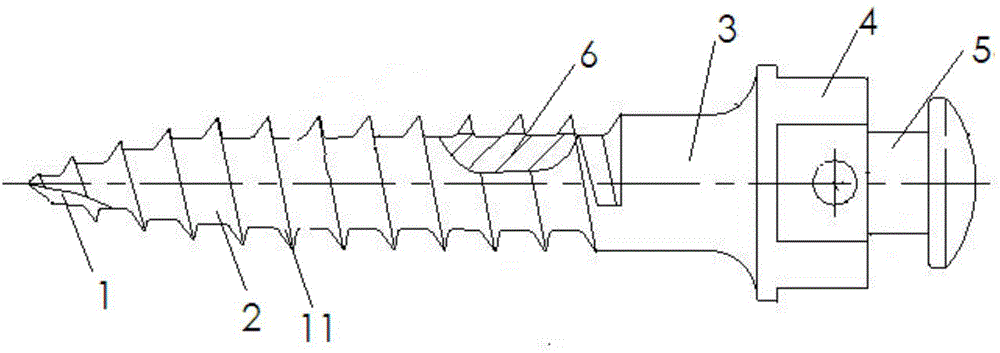

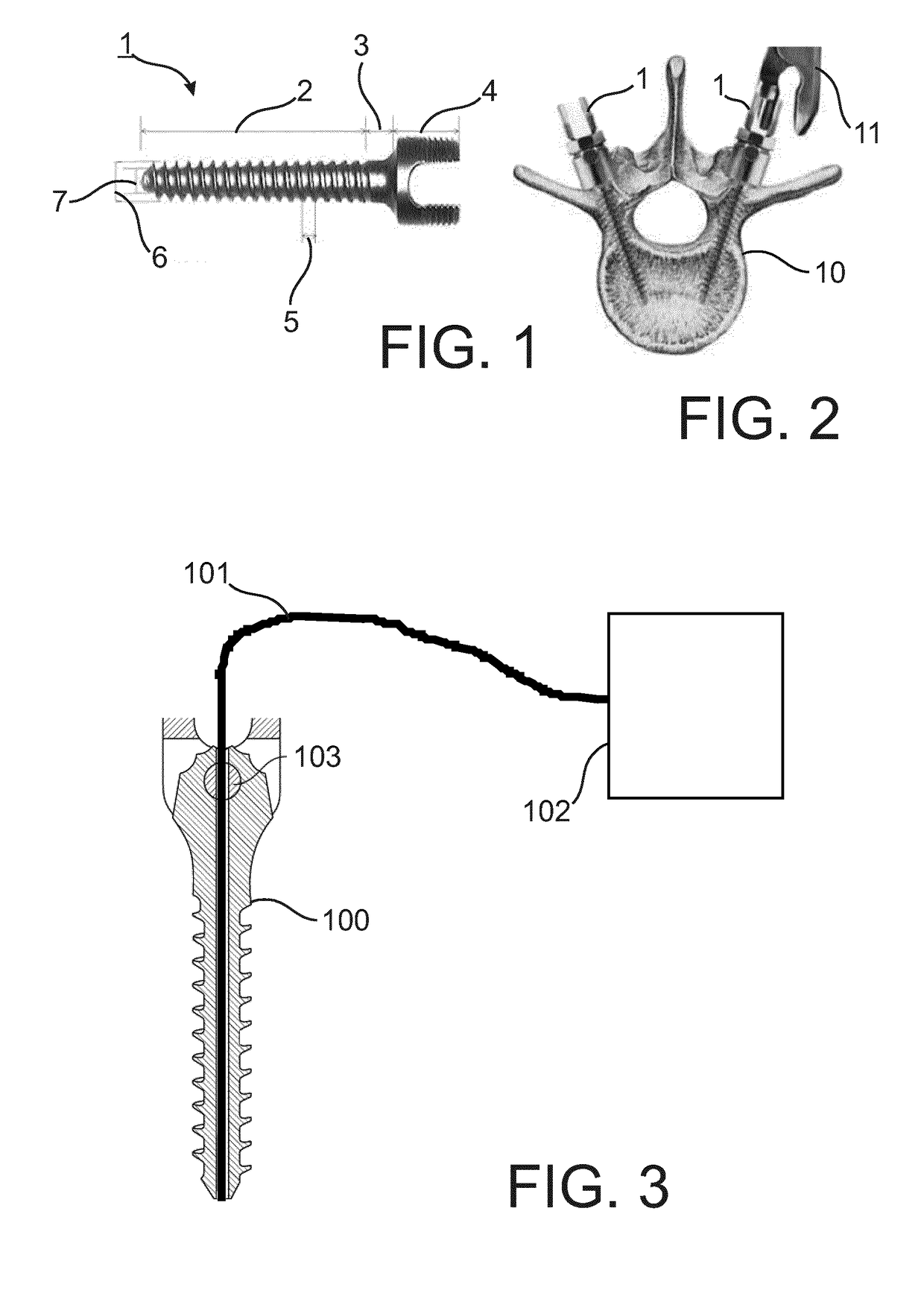

Miniature anchorage screw and correcting device with same

ActiveCN104622591AAvoid the phenomenon of circumferential rotational displacementIncreased circumferential stabilityOthrodonticsEngineeringCavity wall

The invention discloses a miniature anchorage screw and a correcting device with the same. A circumferential stabilizing groove is formed in a screw rod main body and is arranged in the tail end of the screw rod main body. The circumferential stabilizing groove comprises a first cavity wall, a second cavity wall and a cavity formed by the first cavity wall and the second cavity wall; the surface where the first cavity wall of the circumferential stabilizing groove is located is vertical to the surface where a threaded guide of the screw rod main body is located; the length of the cavity is equal to the distance among 3-4 tooth-shaped bodies, and the depth of the cavity is equal to the height of a tooth; the first cavity wall and the screw rod main body form a rotary cutting angle; and the rotation direction of the rotary cutting angle is opposite to the implanting rotation direction of the screw rod main body. After the anchorage screw is implanted to a gum, a compact bone grows to fill the circumferential stabilizing groove, so that the implanted miniature anchorage screw obtains a resistance surface along the tangential direction of a circumference, and the phenomenon of circumferential rotary displacement of the implanted miniature anchorage screw is avoided. By using the miniature anchorage screw, the circumferential stability of the miniature anchorage screw can be improved, and the condition that the deformity collecting effect is reduced because of harmful release of a traction force is avoided.

Owner:杭州西湖生物材料有限公司

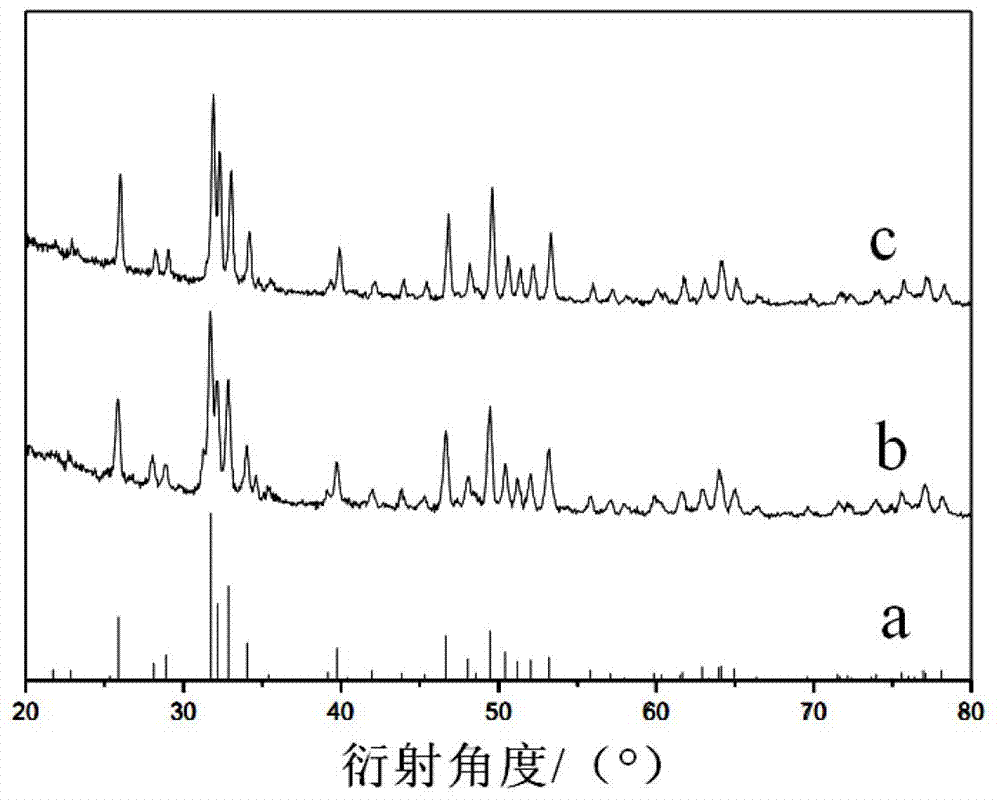

Renewable green environment-friendly material and preparation method and application thereof

InactiveCN103495375AWide variety of sourcesLow priceOther chemical processesWater/sewage treatment by sorptionEnvironmental resistancePorosity

The invention provides a renewable green environment-friendly material and a preparation method and application thereof. The renewable green environment-friendly material is prepared by calcining an animal bone at a temperature of 500 to 650 DEG C to remove organic components so as to form a porous structure and then taking out a sintered product for air cooling. The environment-friendly material comprises a porous compact bone with porosity of 42 to 51.5% and a porous spongy bone with porosity of 75 to 85% obtained after calcination of the animal bone, and the main component of the material is hydroxylapatite with a crystal grain size of 100 to 300 nm. The environment-friendly material is applicable to treatment of heavy metal ions in wastewater. In use, the environment-friendly material is put into wastewater for treatment of the wastewater. The environment-friendly material has the advantages of strong renewability, greenness, energy conservation and environment friendliness; the preparation method is simple, needs low cost, is suitable for industrial production, can fully utilize the resource of waste animal bones and reduces environmental pollution; the material has a high heavy metal ion adsorption rate, as high as more than 90.1%, so the material has wide application prospects.

Owner:XI AN JIAOTONG UNIV

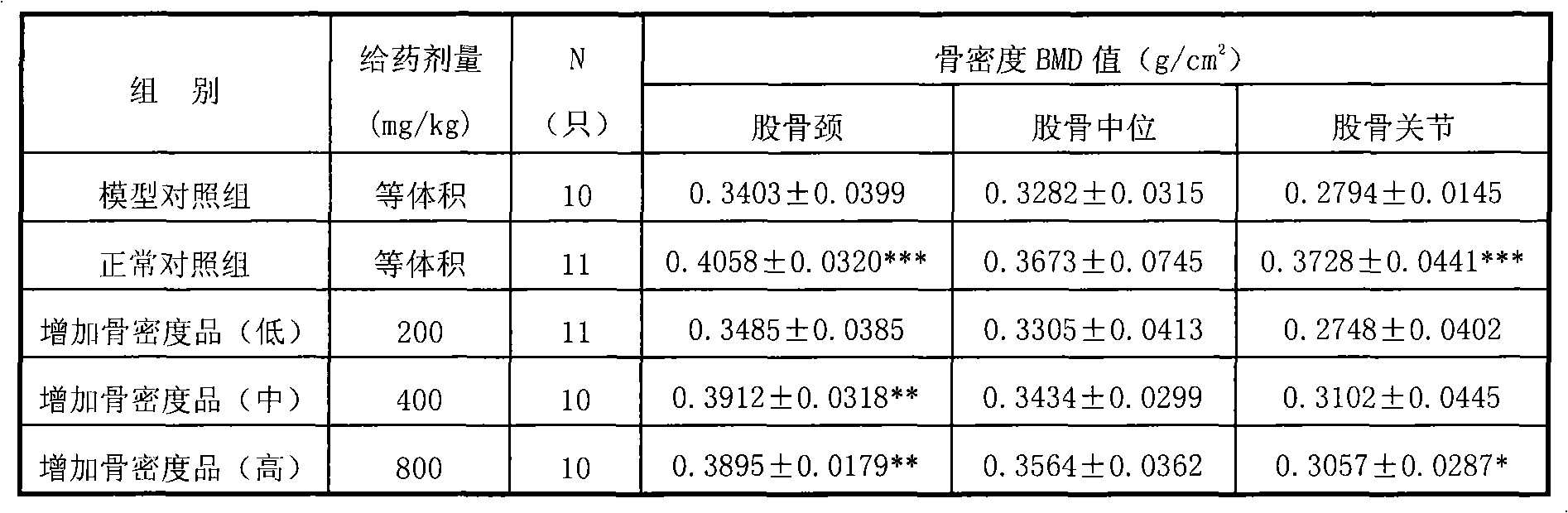

Health food having function of increasing compact bone substance density

ActiveCN101292739AIncrease bone density functionEnhanced bone densityFood shapingFood preparationBone densityAdditive ingredient

The invention discloses a health-care food having the function of increasing the density of bones. The health-care food is prepared by the active components comprising radix astragali, cortex eucommiae, rhizoma drynariae, glucosamine hydrochloride, soy isoflavones and collagen protein. The health-care food of the invention is characterized by combining traditional Chinese medicinal herb features with modern medical research, thus causing various components to be prescribed reasonably and to be matched with each other for sharing and achieving the health care function by various approaches and multiple layers.

Owner:INFINITUS (CHINA) CO LTD

Preparation method for bone specimen used in medical teaching

The invention provides a preparation method for a bone specimen used in medical teaching. The method comprises the following steps: collection and treatment; cooking; cleaning; burying with soil; cleaning; degreasing; bleaching; disinfection; and spraying of a colorless transparent crystal paint. The method is characterized in that a cooking method is combined with a soil burying method, so soft tissue removal is more thorough compared with the simple cooking method, a preparation period is shorter compared with the simple soil burying method, and the method only takes about 6 months and is thus reduced in preparation time; no damage is posed to compact bone substances and cancellous substances, and the fine structure of a bone does not change and is identical to the fine structure of a living body; and though paint treatment, the bone is isolated from air, so the bone specimen is not prone to mildew, reduces pollution and irritation to human beings and ensures the health of a user.

Owner:JIAMUSI UNIVERSITY

Bone density-increasing and senility-postponing capsule formulation

InactiveCN1762386AImprove life expectancyHas an anti-aging effectOrganic active ingredientsSkeletal disorderIsoflavonesVitamin B6 synthesis

The present pertains to the field of traditional Chinese medicine, more specifically a capsule for increasing compact bone substance density and delaying senescence, which is prepared from soybean isoflavones, shark cartilage micropowder, calcium carbonate, vitamin B6, folic acid and medicinal auxiliary materials.

Owner:SHANGHAI BEST HEALTH PROD

Pill for treating cold bone paralysis

InactiveCN101342289AAchieve antibody recoveryEliminate lesionsInanimate material medical ingredientsSkeletal disorderLiver and kidneyAnkylosing spondylitis

The present invention relates to a Chinese patent medicine which is prepared in the form of capsules and used for treating a plurality of types of proplapse of lumbar intervertebral disc, spinal stenosis, regressive changes, hyperplasia of all parts of bones, ankylosing spondylitis, and a plurality of types of rheumatism. The formula comprises snow lotus on the great icy mountain, holly, Japanese teasel fried in salt, roasted Chinese ephedra, and other types of Chinese medicine. The Chinese patent medicine has the functions of eliminating the pathological changes caused by various factors, strongly compensating the deficiency of liver and kidney, resulting in the physiological changes of bones from the pathological changes, absorbing and rehabilitating the spongy bone and the compact bone, and realizing the recovery of bone diseases. The therapy not only has rapid effects, but is also suitable for patients which can not be cured in various types of treatment. Moreover, the Chinese patent medicine has proven to have no case of relapse.

Owner:刘晓兵 +1

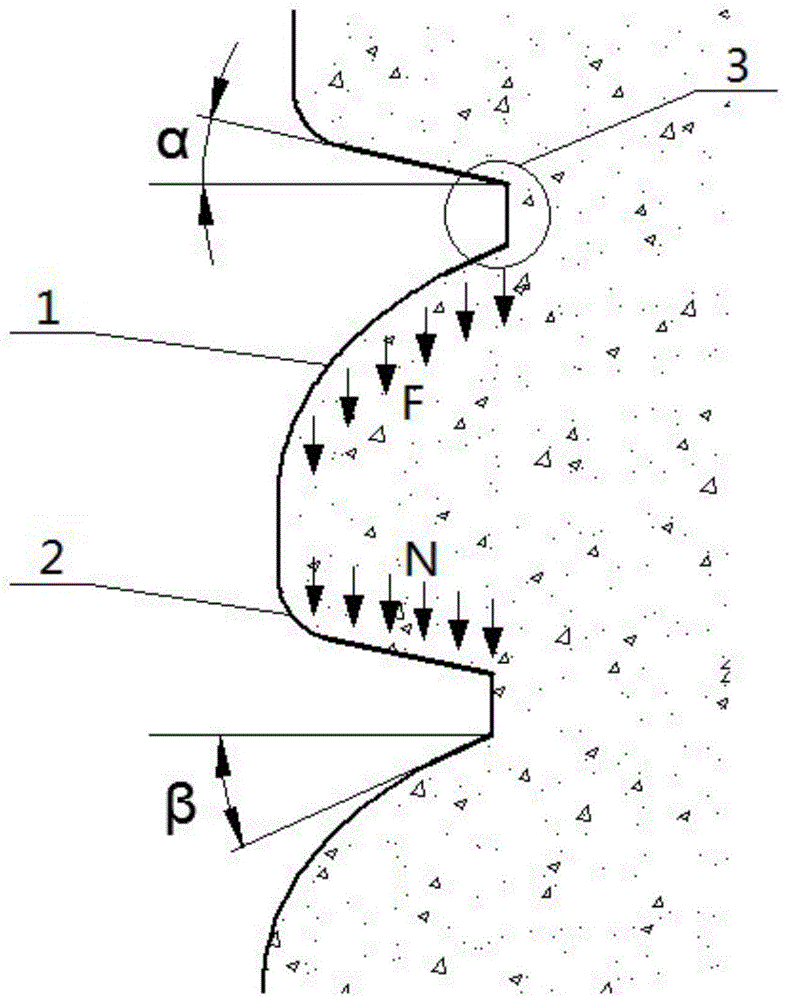

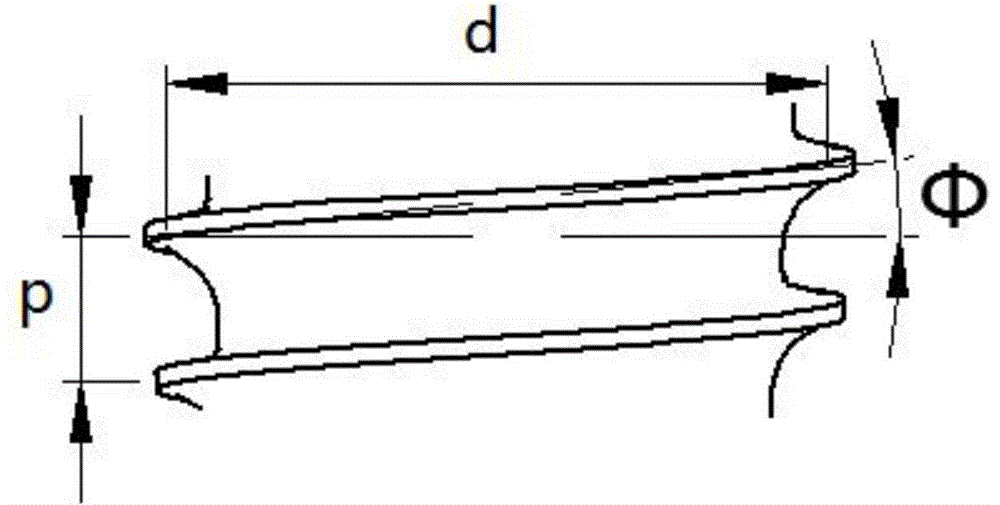

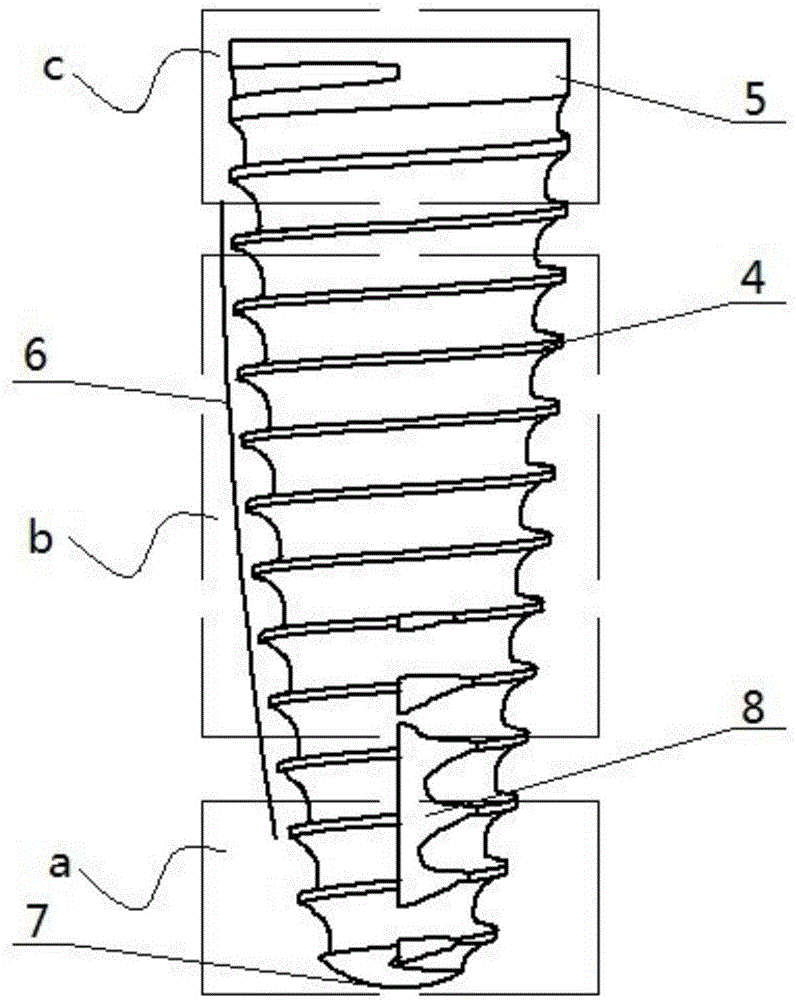

Oral implant with asymmetric thread structure

The invention discloses an oral implant with an asymmetric thread structure. The oral implant comprises an implant part c, an implant part b and an implant part a in sequence from top to bottom; a column body is arranged at the contact part of the implant part c and a compact bone; the implant part b adopts a cone with a cambered surface; the bottom surface of the implant part a is a circular arc surface; an asymmetric thread is arranged on the oral implant; the depth of the asymmetric thread is gradually decreased from the implant part b to the implant part c and the implant part a on the two sides of the implant part b; the inclined angle between the upper edge of the asymmetric thread and the horizontal plane is smaller than that between the lower edge of the asymmetric thread and the water level; a circular arc surface is arranged at the transition part of either the upper edge or the lower edge of the asymmetric thread and the vertical surface of the bottom diameter of the asymmetric thread; the helix angle of the asymmetric thread is varied along with the variation of the diameter of the implant; the thread structure can transfer a bite force well, has a good retention force, and can avoid stress concentration; the screw pitch is reasonable, the helix angle has self-lock performance, and the stability is improved; the variable thread depth can reach the optimal bone bonding strength.

Owner:DALIAN UNIV

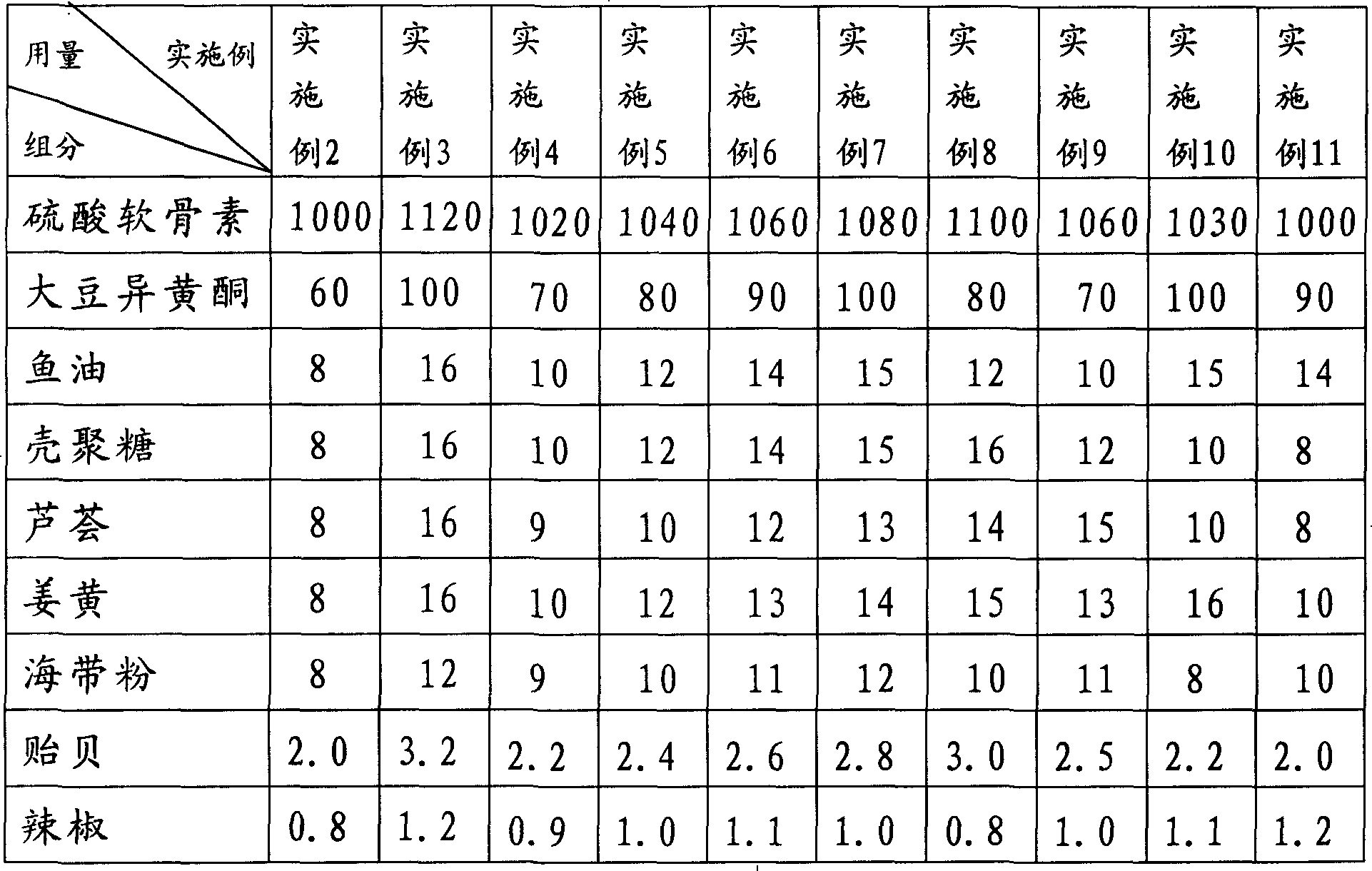

Health food with oxidation resistance and compact bone substance density intensification functions

InactiveCN101011565AImprove biological activityFreedom of movementOrganic active ingredientsAntinoxious agentsBone densityFish oil

The invention discloses a health food having the effects of oxidation resistance and increasing compact bone substance density, wherein the raw materials include chondroitin sulfate 250-280 parts, soybean isoflavones 15-25 parts, mussel 0.5-0.8 part, sea-tangle 2-3 parts, fish oil 2-4 parts, chitosan 2-4 parts, curcuma longa 2-4 parts, pepper 0.2-0.3 part and aloe 2-4 parts.

Owner:高树华

Compound containing vinegar-egg powder and application thereof

InactiveCN100379359CPrevention and treatment of osteoporosisIncrease bone densityFood preservationSkeletal disorderBiotechnologyBone density

Owner:HANGZHOU XINFU TECH CO LTD

Novel medical sponge stent material with collagen combined with calcium phosphate and preparation method

The invention discloses a novel medical sponge stent material with collagen and calcium phosphate as raw materials and a preparation method, provides a novel medical sponge stent material with collagen combined with calcium phosphate and a preparation method, and belongs to the technical field of biomedical materials. The problem that in osteochondral injury treatment at present, repair of cartilage tissue and infusion of the cartilage tissue to be repaired and a compact bone part (namely, a hard bone part) connected with the cartilage tissue can not be carried out at the same time is solved, and the defect that a present clinical collagen / calcium phosphate bone repair material can not well repair osteochondral tissue injury is overcome.

Owner:TIANJIN SANNIE BIOENG TECH

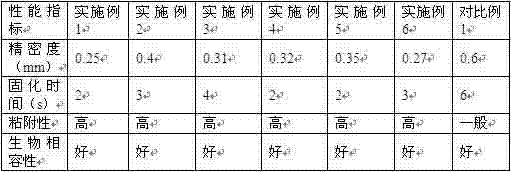

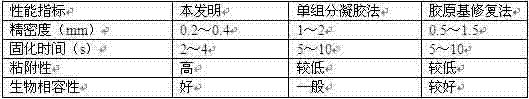

Method for repairing bone tissue by utilizing 3D printing double-component hydrogel

ActiveCN107998448APrecision RestorationDense repairAdditive manufacturing apparatusTissue regenerationFiberCalcium silicate

The invention provides a method for repairing a bone tissue by utilizing 3D printing double-component hydrogel. The method comprises the following steps: spraying out hydrogel A and hydrogel B througha double-spray-head 3D printer, and performing reaction to generate calcium silicate in situ in a deposition process, thereby realizing bone repair; the hydrogel A is prepared from the following components in parts by weight: 40-50 parts of methacryloyl glycinamide hydrogel, 10-15 parts of monetite, 13-18 parts of calcium sulfate, 0.3-0.6 part of a nonionic surfactant and 16.4-36.7 parts of ethylacetate; and the hydrogel B is prepared from the following components in parts by weight: 22-30 parts of silicon dioxide gel, 18-26 parts of silicic acid, 25-32 parts of polylactic acid staples, 0.2-0.5 part of a zwitterionic surfactant and 11.5-34.8 parts of ethanol. The method can effectively realize precise and compact bone repair through reactive crystallization of the double-component gel which can be stored for a long time independently, is high in curing rate of repaired bones, is good in adhesion property, is good in biocompatibility, and greatly improves the bone injury heal effect;and moreover, the whole repair method is simple to operate, adopts easily available raw materials, is low in cost, and can be popularized and applied.

Owner:山东明河药业有限公司

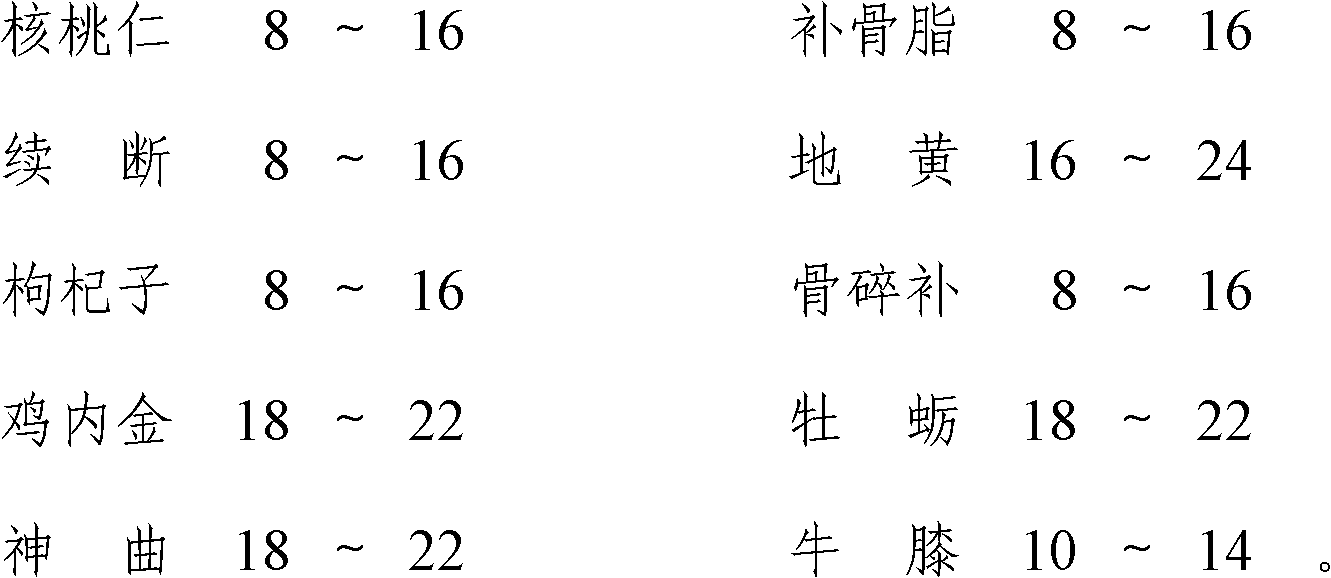

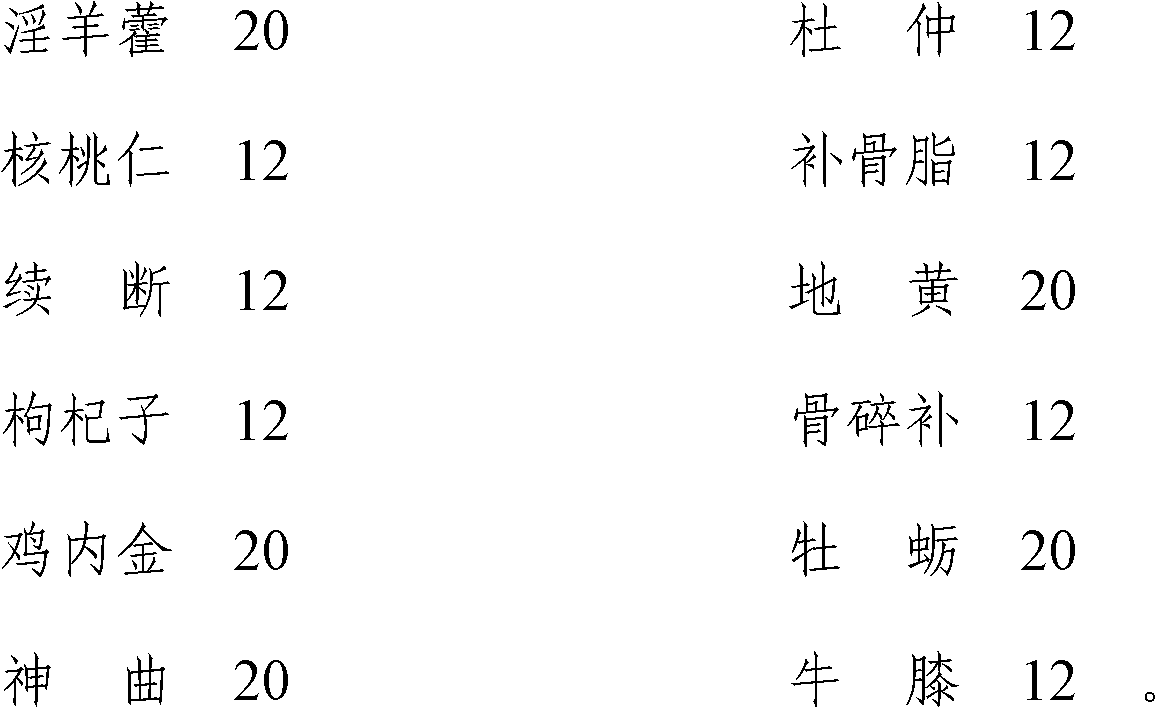

Bone health care marrow filling capsule

InactiveCN102247486ADefinite curative effectGood effectAntipyreticAnalgesicsSexual functionSide effect

The invention relates to a bone health care marrow filling capsule, disclosing a bone health care marrow filling capsule. In the bone health care marrow filling capsule, 12 types of medicines, such as bone fat, herba epimedii, Eucommia ulmoides, walnut, teasel root, rehmannia, barbary wolfberry fruit, drynaria rhizome, endothelium corneum gigeriae galli, oyster, medicated leaven and the root of bidentate achyranthes serve as bulk pharmaceutical chemicals and are smashed, decocted, condensed, dried, screened and the like to obtain the bone health care marrow filling capsule. The bone health care marrow filling capsule has the peculiar curative effect on enhancing sexual functions, eliminating toxins, lowering blood lipid, replenishing essence, replenishing marrow, compacting bone and strengthening tendon. The bone health care marrow filling capsule is clinically applied to rheumatoid arthritis, senile osteoporosis and the like, has exact curative effect, obvious effect and no toxic or side effect and is safe and effective Chinese medicine formula.

Owner:长春市南关区中医院

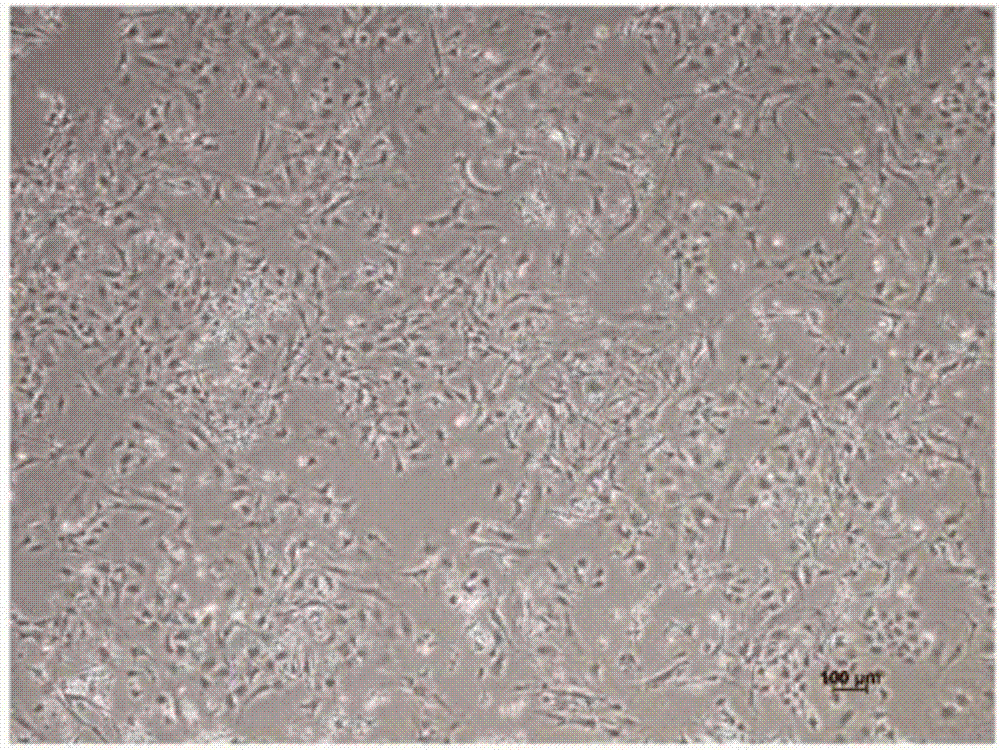

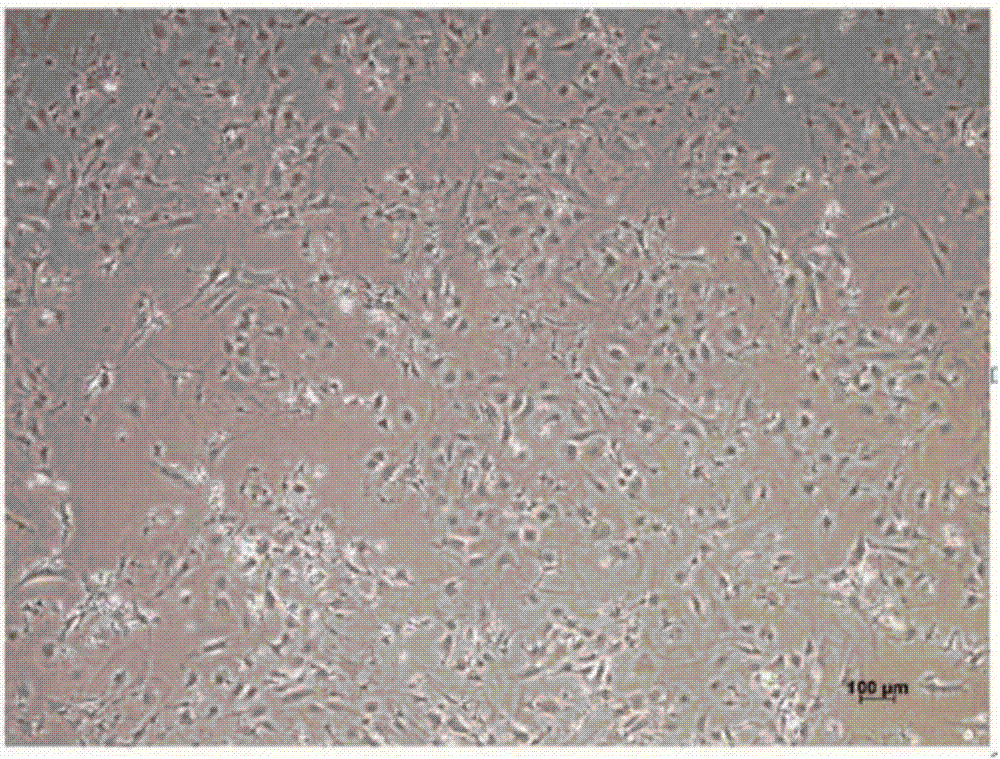

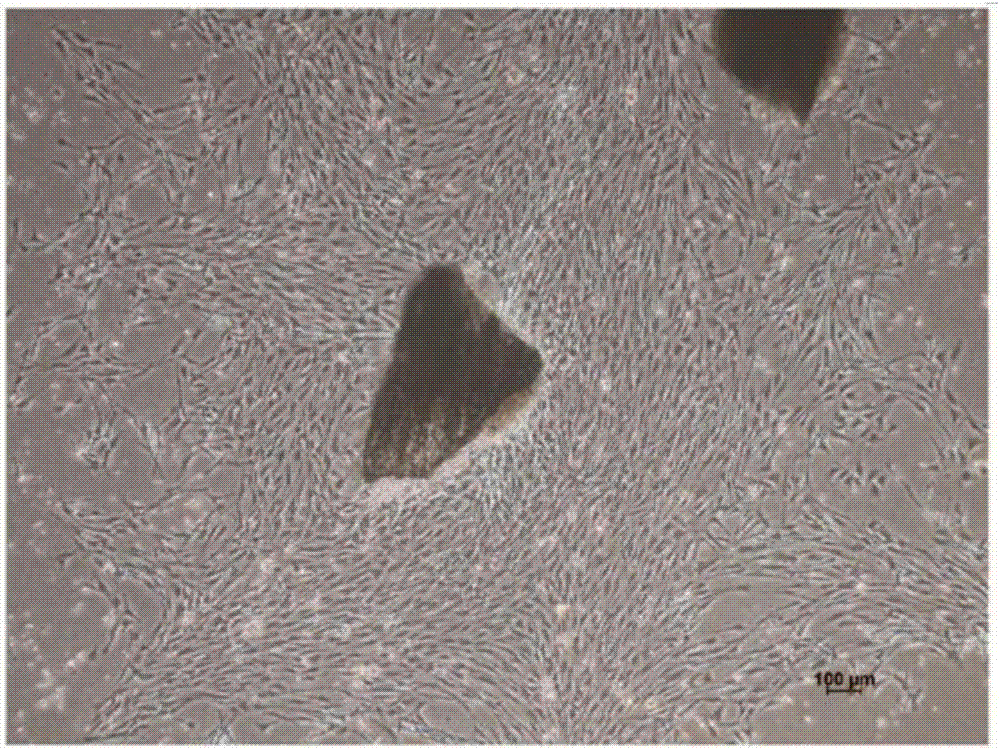

Method of high-effectively obtaining mesenchymal stem cells from compact bone of mice

ActiveCN107287158AReduce the time required for cultivationReduce the amount of solutionCell dissociation methodsSkeletal/connective tissue cellsSurface markerSystems research

The invention relates to methods of obtaining mesenchymal stem cells and is to provide a method of high-effectively obtaining mesenchymal stem cells from compact bone of mice. The method of high-effectively obtaining mesenchymal stem cells of mice includes the steps of: separating mesenchymal stem cells of mice, performing primary culture, and performing amplification culture to the mesenchymal stem cells of mice. The method greatly reduces the time of cell culture and can greatly increase quantity of produced cells, and is less in pollution of non-MSCs adherent cells. The invention, for the first time, discloses a multi-time bone sheet adhesion culture method, which can increase the yield of cells by 3-5 times. Through systematic researching on biological characteristics, such as growth status, surface markers, multidirectional differentiative potential and the like, of the MSCs from the compact bone of mice, it is proved that after 10 times of amplification culture in vitro, the cells still have strong characters of stem cells and can satisfy demands in experiment and researching. The method can quickly and high-effectively produce the stem cells. The obtained stem cells has high proliferation and growth speed and high differentiative potential.

Owner:ZHEJIANG UNIV

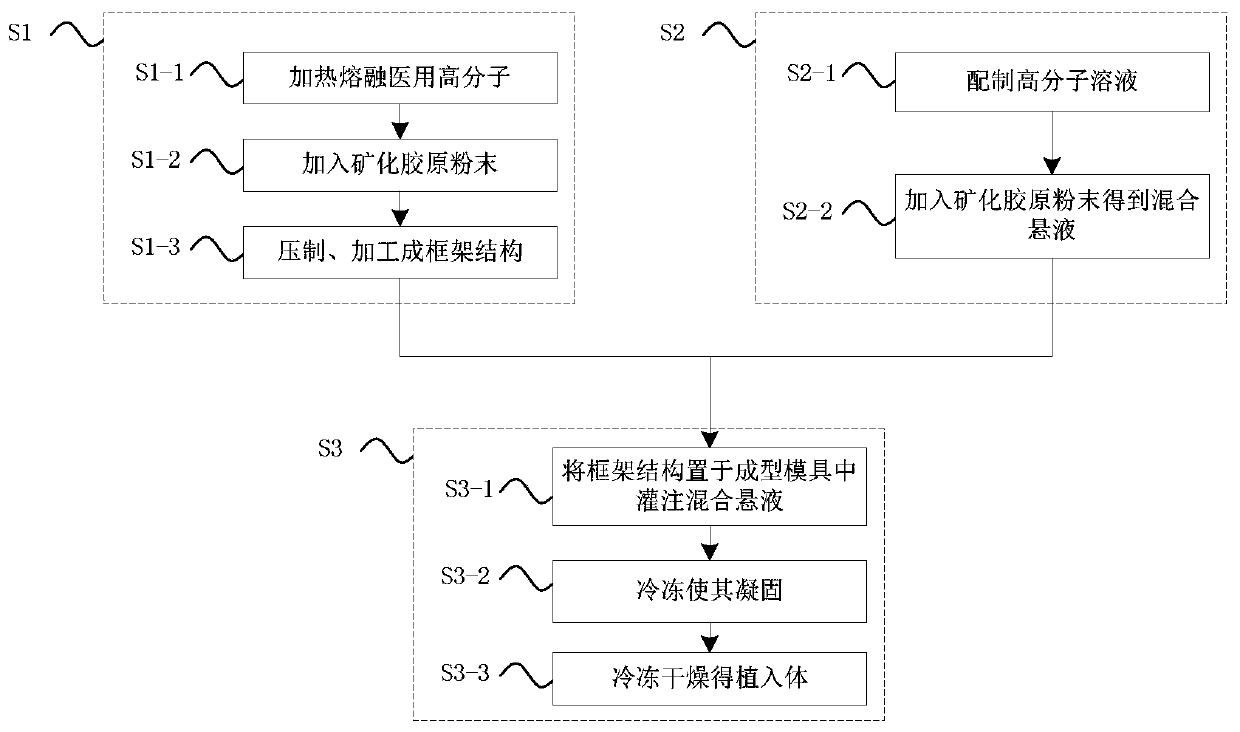

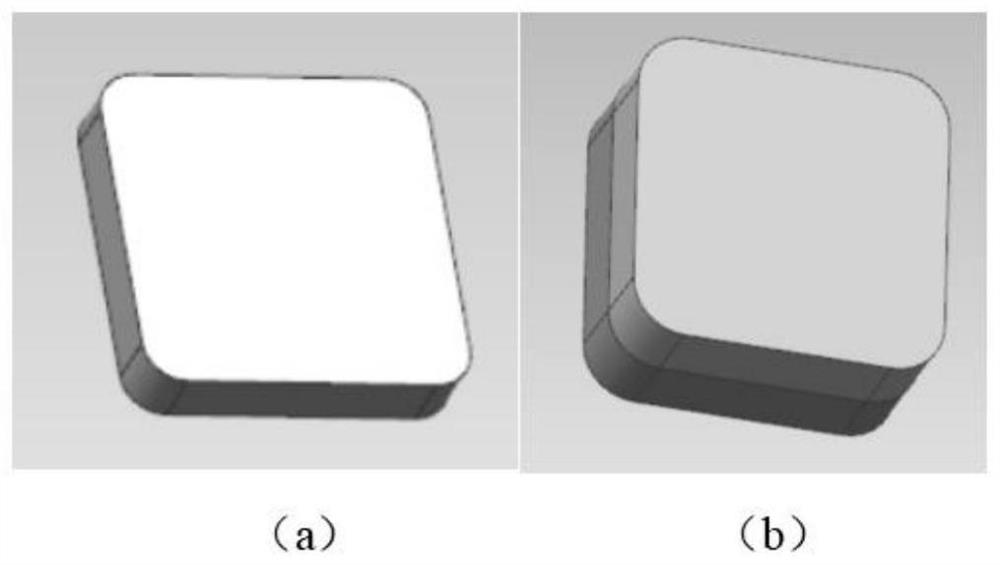

Multi-stage biomimetic mineralized collagen-based skull repair implant and preparation method thereof

ActiveCN110101487AHigh mechanical strengthAchieve step-by-step biomimicryTissue regenerationSkullMass ratioFreeze-drying

The invention provides a multi-stage biomimetic mineralized collagen-based skull repair implant and a preparation method thereof. The implant comprises biomimetic compact bone for forming a frame structure and biomimetic porous bone for wrapping the frame structure, wherein the biomimetic compact bone is prepared by heating, mixing, cooling and shaping mineralized collagen and a medical high-molecular material in a mass ratio of (2:1)-(1:4); the biomimetic porous bone is prepared by freeze-drying a mixed suspension prepared from mineralized collagen and a medical high-molecular material in a mass ratio of (2:1)-(1:4), the biomimetic porous bone is provided with micron-sized communicating pores, the pore diameter distribution is 5-500 micrometers, and the porosity is 60-90%. The biomimeticcompact bone is combined with the biomimetic porous bone to prepare the multi-stage biomimetic mineralized collagen-based skull repair implant, wherein the biomimetic compact bone of the frame structure is high in mechanical strength and is used for providing mechanical support; the biomimetic porous bone is provided with the micron-sized communicating pores, quick ingrowth of new bone can be induced, and stage-by-stage bionic design from nanometer to micrometer is integrally achieved.

Owner:TSINGHUA UNIV

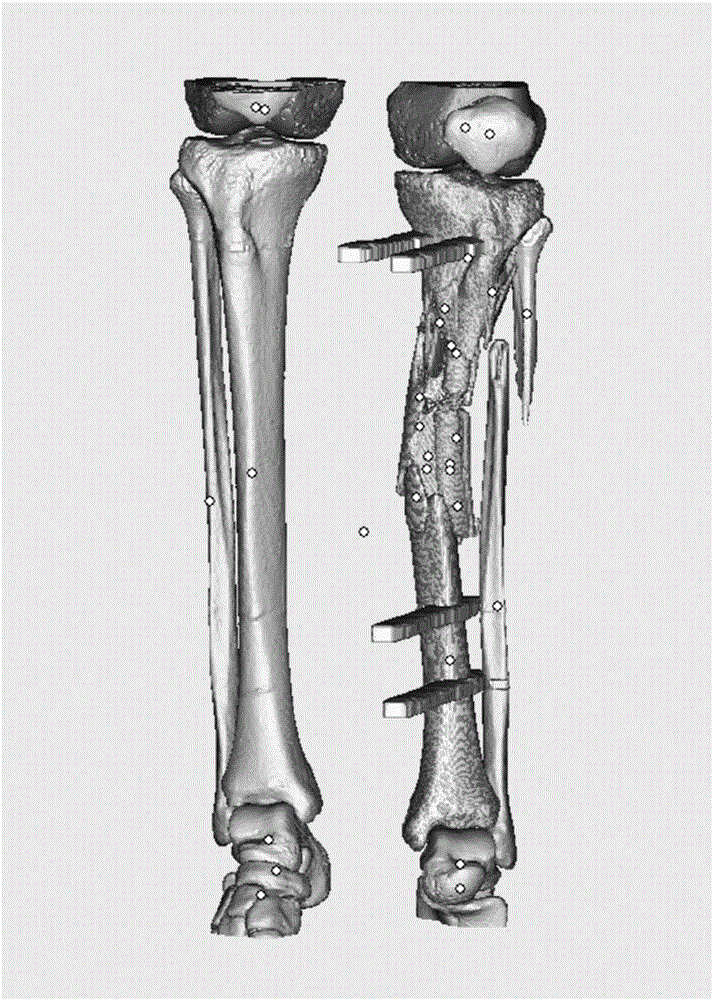

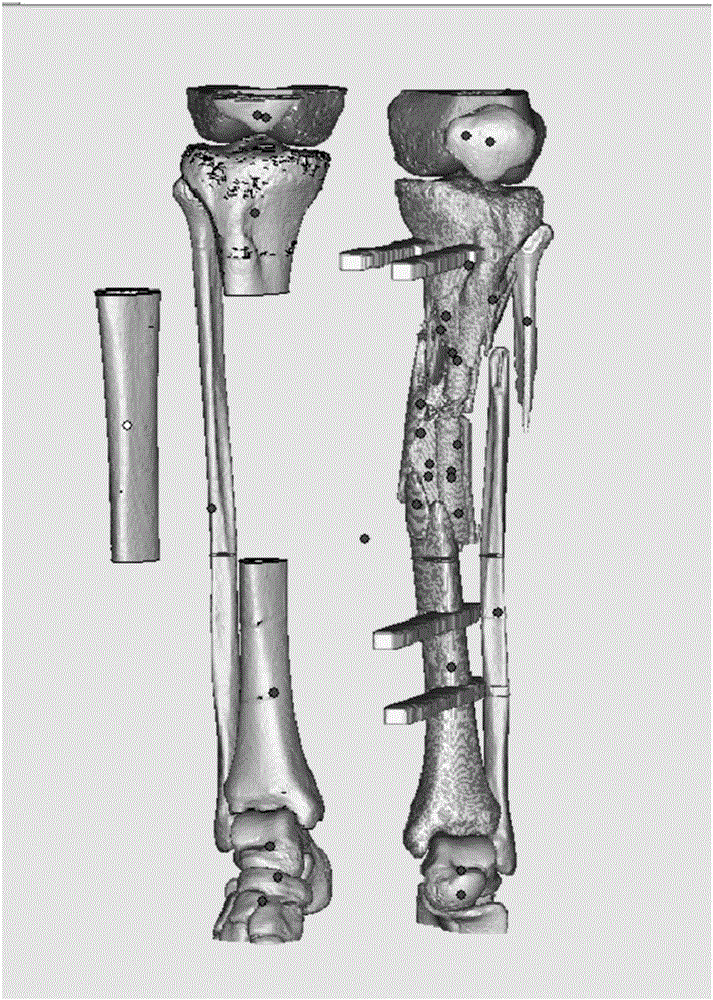

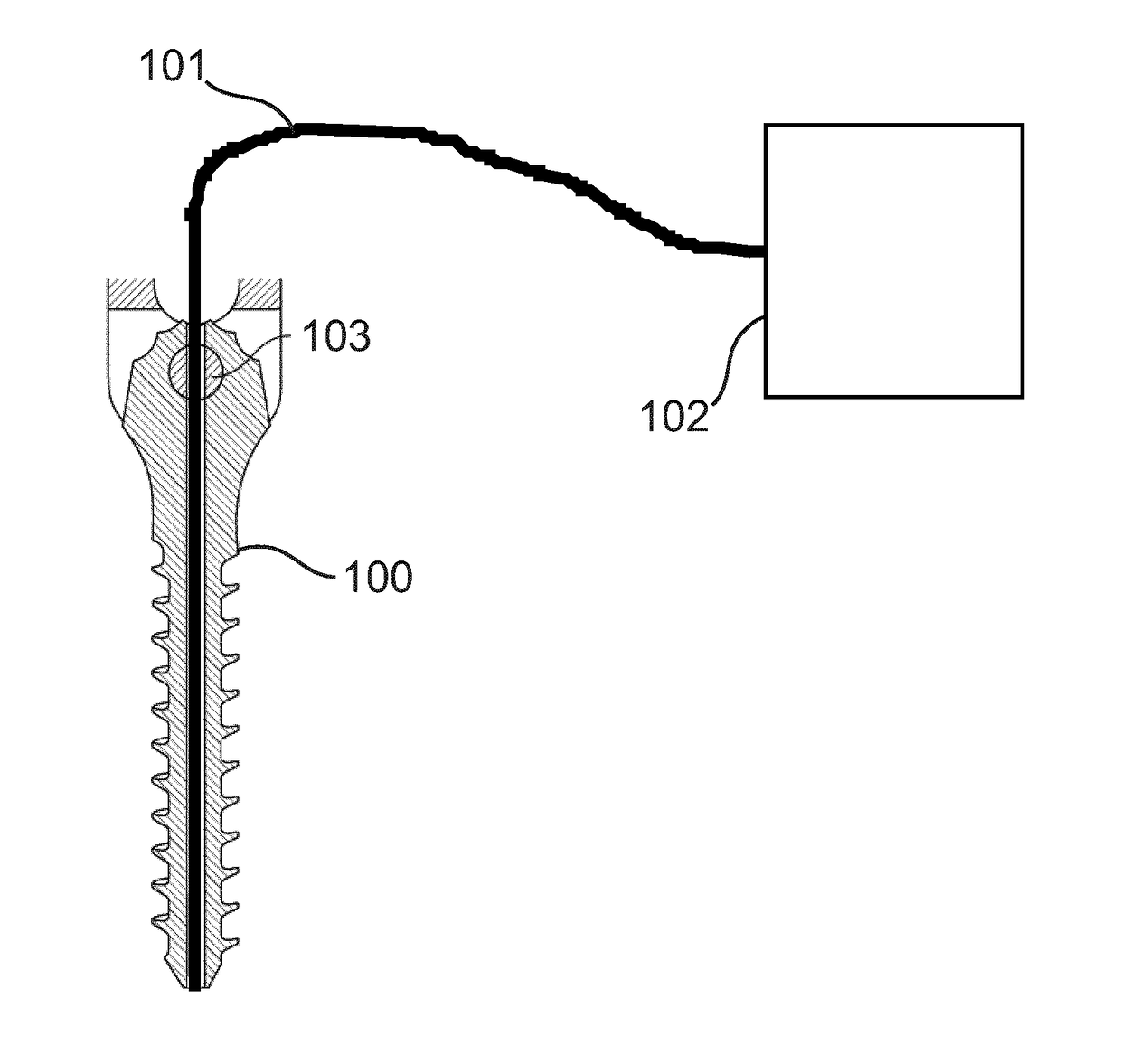

System for implanting in bone tissue

ActiveUS20180280065A1Improved implantAccurate placementInternal osteosythesisFastenersScrew placementBone tissue

Owner:KONINKLJIJKE PHILIPS NV

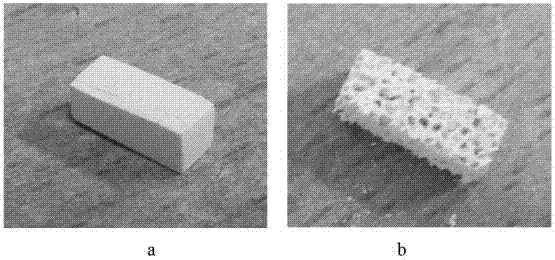

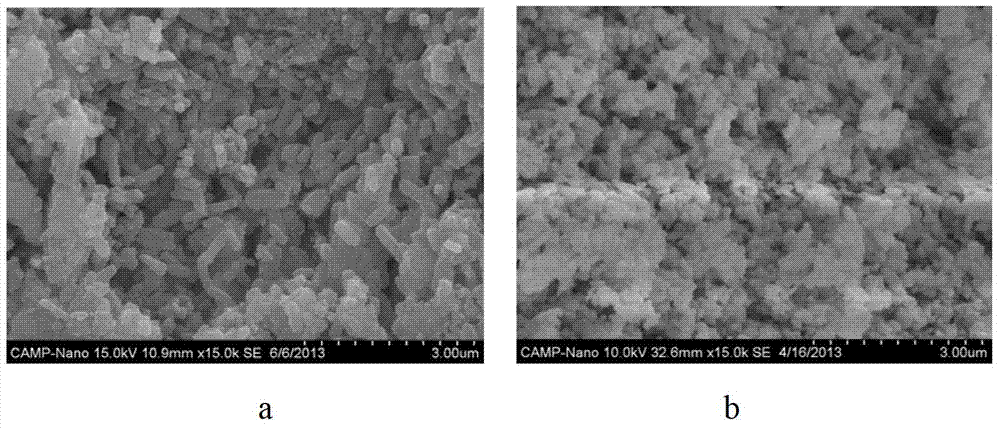

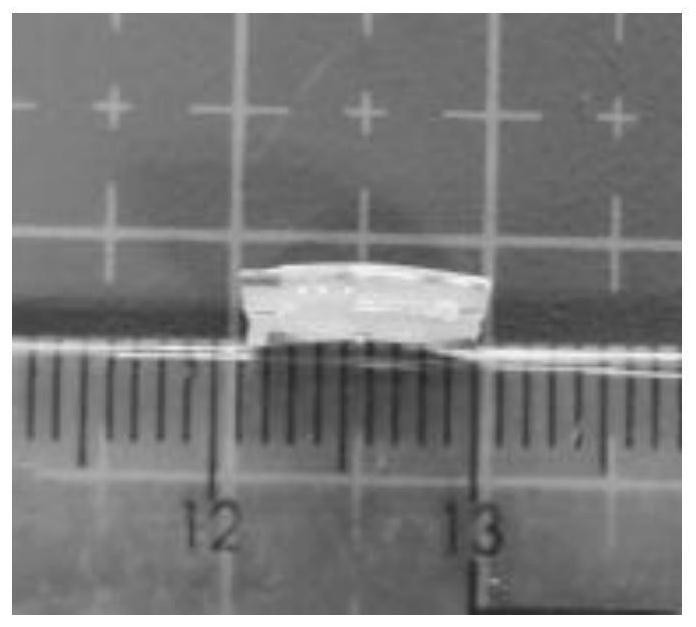

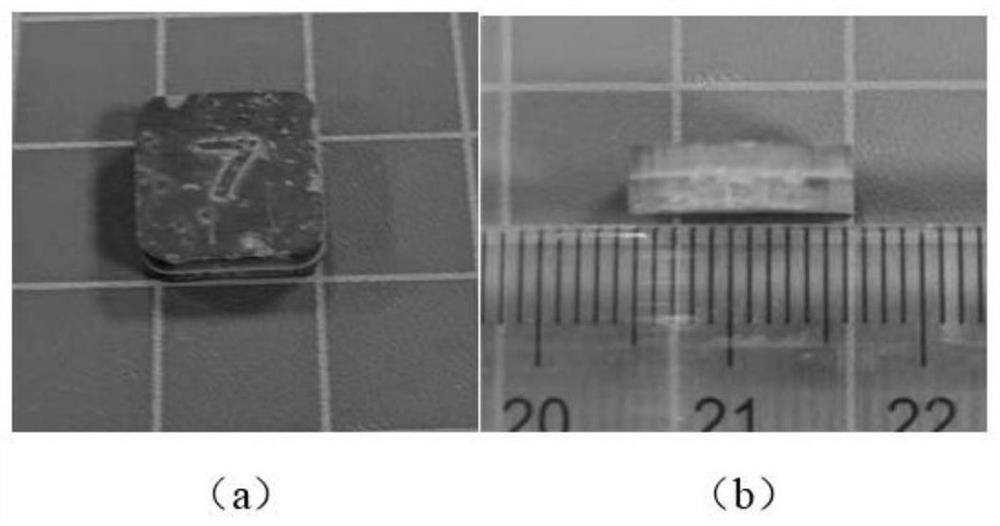

Compact bone matrix and preparation method

ActiveCN104174069AConducive to regenerative repairGood biocompatibilityProsthesisMedicineBiocompatibility Testing

The invention discloses a compact bone matrix and its preparation method. The method for preparing the bone matrix (a compact demineralized bone matrix) comprises the following steps: (1) diaphysis of isolated animal bones is taken and is immersed and processed by the use of a surfactant solution; (2) a product obtained from the step (1) is immersed and processed by the use of aqueous alkali; (3) a product obtained from the step (2) is immersed and processed by the use of a surfactant solution; (4) a product obtained from the step (3) is immersed and processed by the use of an acid solution; (5) a product obtained from the step (4) is immersed and processed by the use of aqueous alkali; (6) a product obtained from the step (5) is immersed and processed by the use of an irradiation protective reagent solution with the pH of 6.0-7.5; and (7) a product obtained from the step (6) undergoes freeze drying and irradiation sterilization successively so as to obtain the bone matrix. The bone matrix provided by the invention has advantages of no immunological rejection and good biocompatibility, and can meet mechanical requirements of repaired tissues.

Owner:YANTAI ZHENGHAI BIO TECH

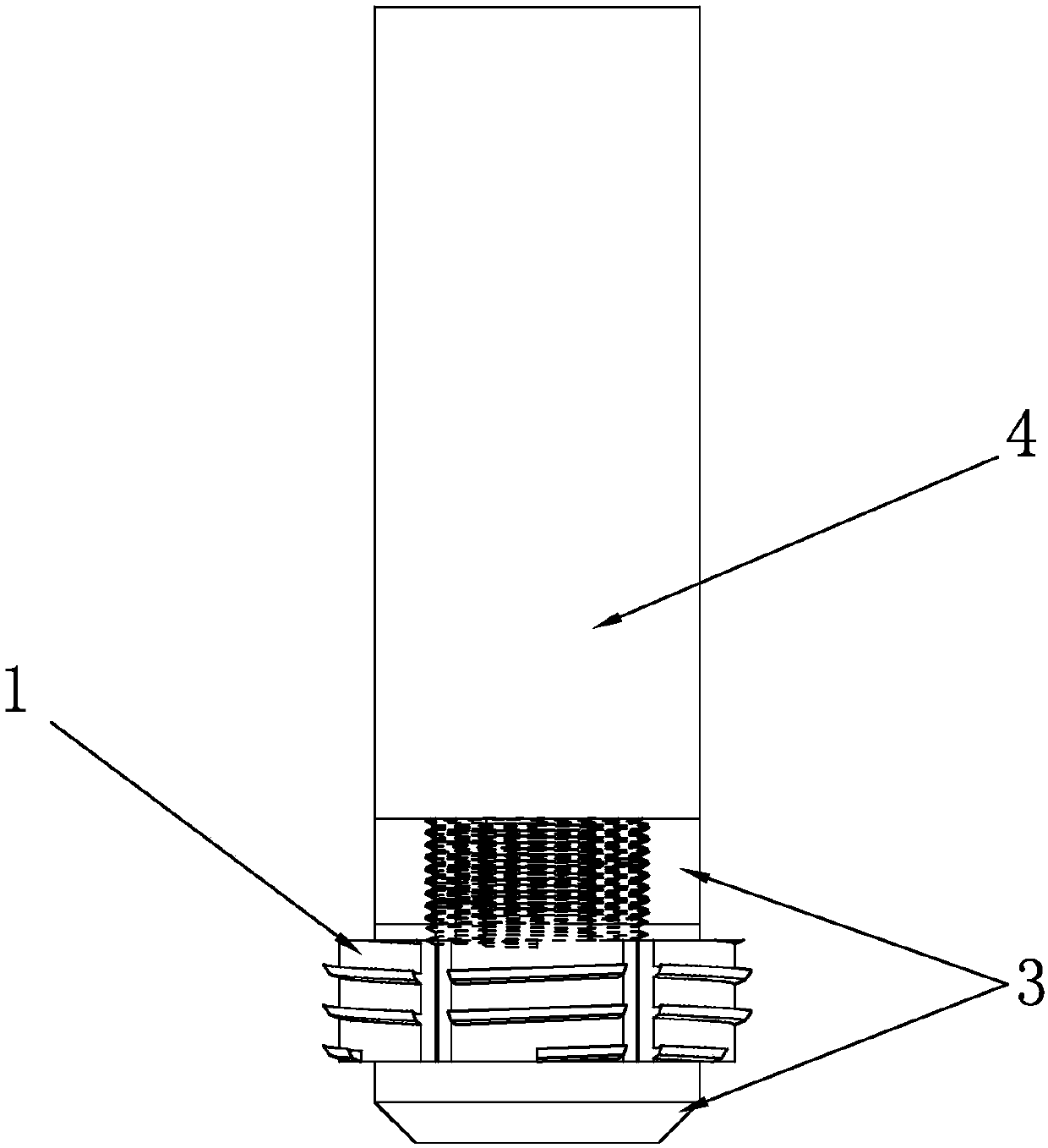

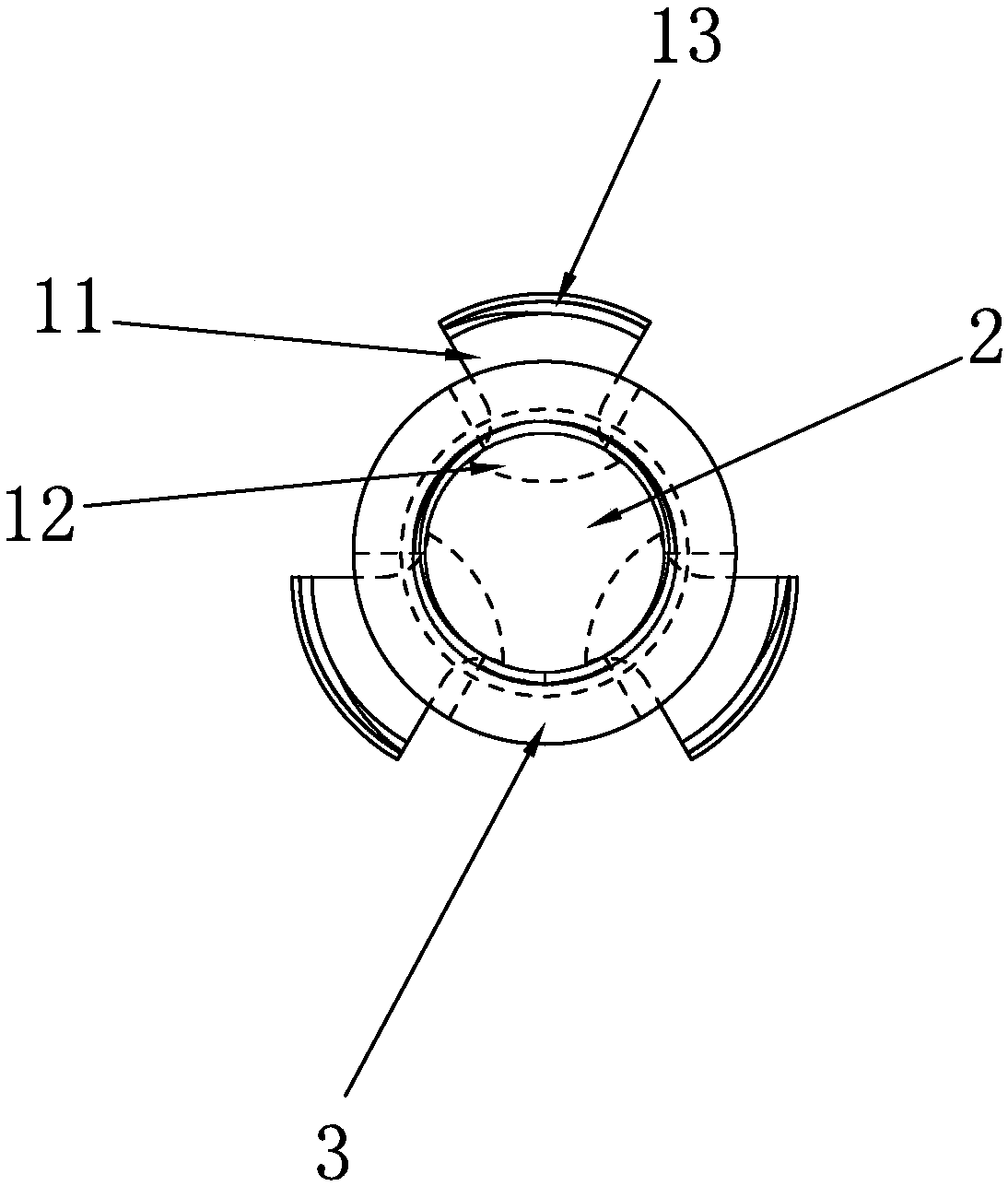

Centrifugal drill bit for tooth planting technology

PendingCN107928817AShorten the recovery cycleAvoid damageDental implantsDental toolsCentrifugationEngineering

The invention discloses a centrifugal drill bit for a tooth planting technology. The centrifugal drill bit comprises a drill body and a plurality of bit edges, a bit edge accommodating chamber is arranged in a position, close to the lower end, of the drill body, the bit edge accommodating chamber is provided with a plurality of gaps penetrating through the sidewall of the drill body, the quantityof the gaps is same to the quantity of the bit edges, the gaps are distributed in an equal included angle manner, the bit edges are slidably placed in the bit edge accommodating chamber, every bit edge comprises a cutter body, a clamping head and a cutter edge, the cutter body is trapezoid, the clamping head is connected with the upper base edge of the cutter body, the cutter edge is connected with the lower base edge of the cutter body, the cutter edge has an arc-shaped shape, the arc radius of the cutter edge is consistent to the radius of the drill body, the clamping heads of the bit edgesare provided with mutually attractive magnetic members, and the widths of the clamping heads are more than the width of the gaps. The centrifugal drill bit can drill bone debris in an alveolar bone while keeping wounds of the oral soft tissues and the compact bone part of the alveolar bone small, so an appropriate installation space is provided for a subsequent dental implant, and the rehabilitation period of patients is greatly shortened.

Owner:广东健齿生物科技有限公司

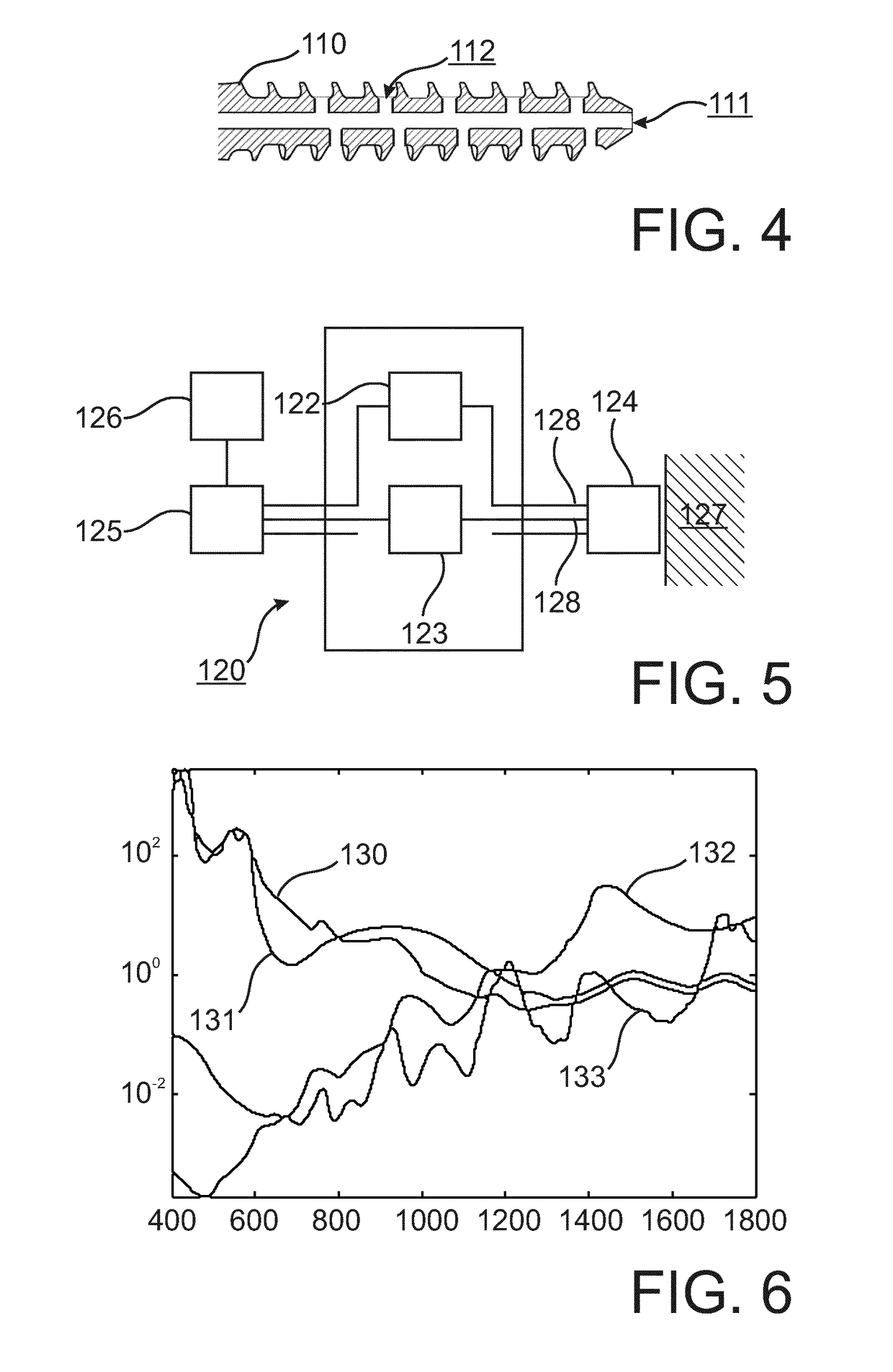

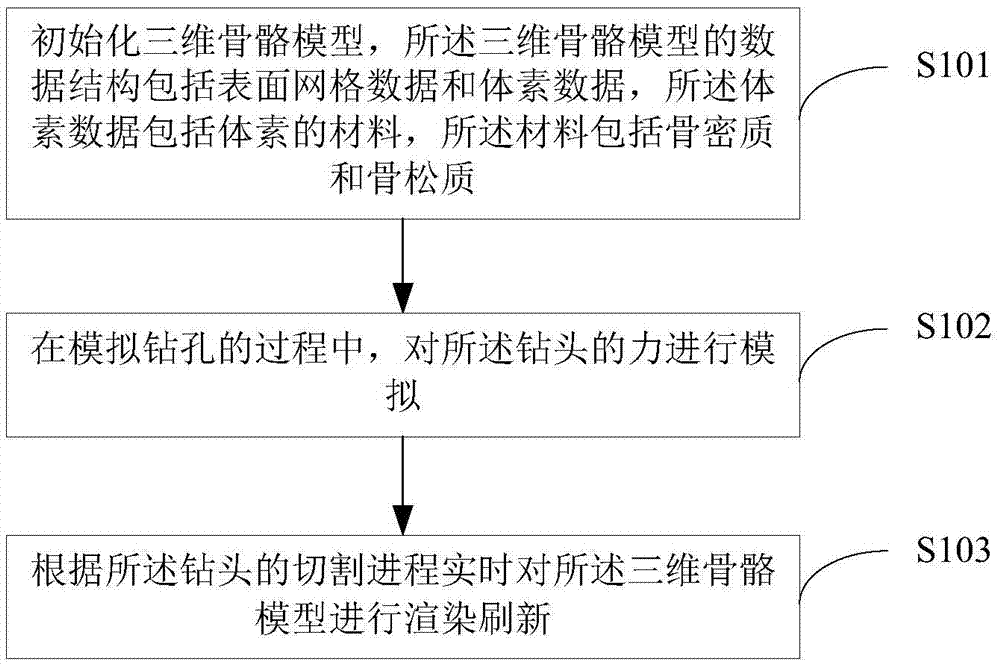

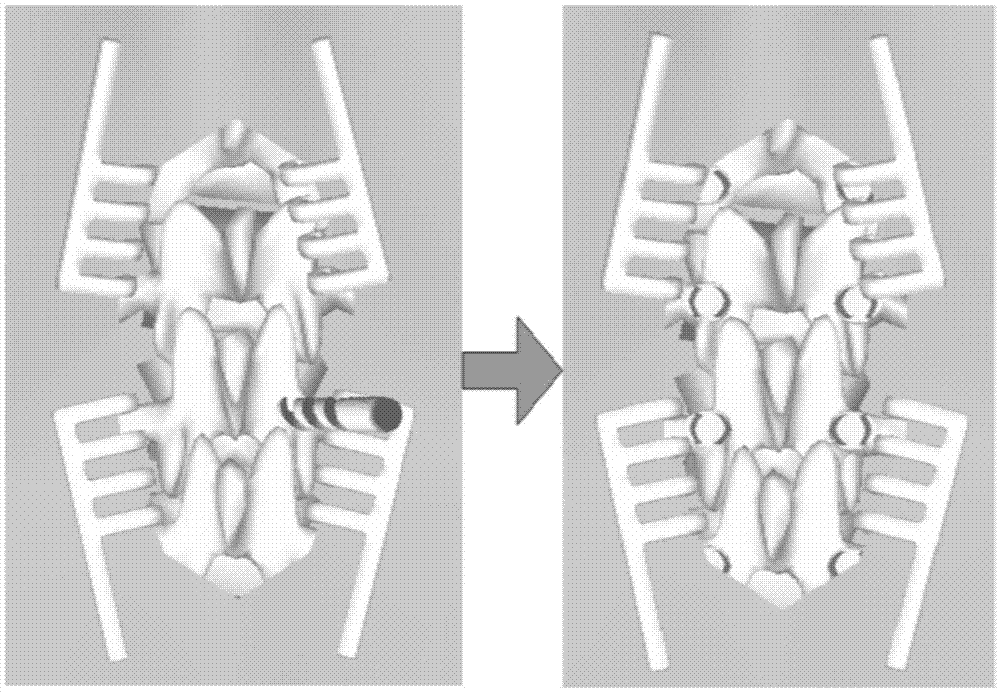

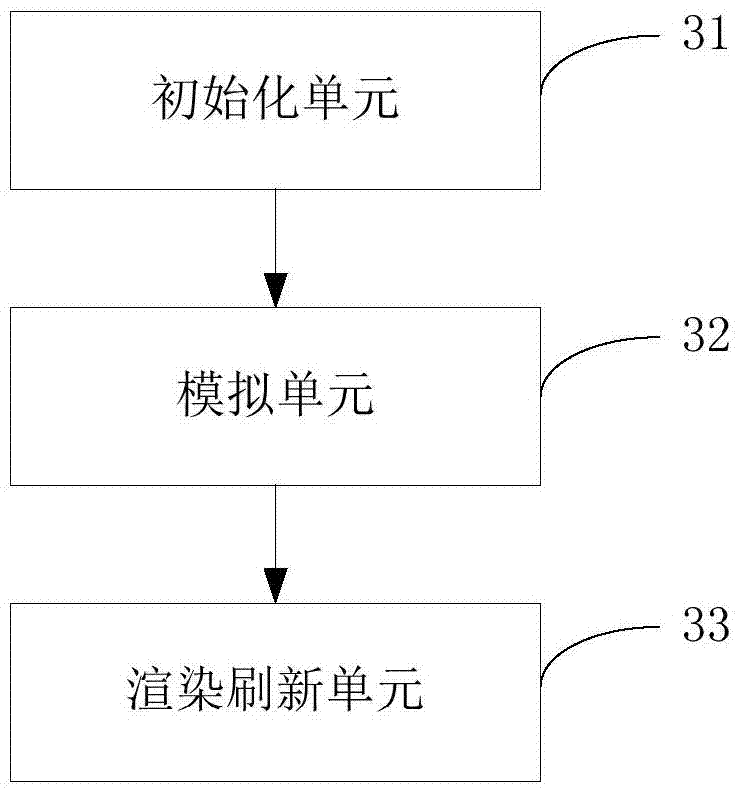

Drilling operation simulation method and apparatus

InactiveCN106920272ADealing with non-uniform featuresIncrease authenticitySpecial data processing applications3D-image renderingVoxelOmega

The present invention is applied to the technical field of virtual reality, and provides a drilling operation simulation method and a virtual reality system. The method comprises: initializing a three-dimensional skeletal model, wherein the data structure of the three-dimensional skeleton model comprises surface mesh data and voxel data, the voxel data comprises a voxel material, and the voxel material comprises the compact bone and the cancellous bone; in the drilling simulation process, based on dFn = (Kn1t1 + Kn2t2)d[omega] and dFf = (Kf1t1 + Kf2t2)d[omega], carrying out simulation on the force of a drill bit; and rendering and refreshing the three-dimensional skeletal model in real time according to the cutting process of the drill bit. According to the technical scheme provided by the present invention, different material properties of different parts of the bone are distinguished, the non-uniformity of the bone material is well processed, and in the process of carrying out virtual reality on the drilling operation, the authenticity and accuracy of the simulation are enhanced.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Bionic human bone based on 3D printing and manufacturing method thereof

PendingCN113402282AAvoid crackingAvoid bendingAdditive manufacturing apparatusTissue regenerationHuman bodyShrinkage rate

The invention discloses a bionic human bone based on 3D printing and a manufacturing method thereof, and relates to the technical field of biological ceramic human bone materials. According to the corresponding relation between the proportion of A-type silicon nitride and B-type silicon nitride contained in the ceramic raw materials of the first-layer ceramic piece and the shrinkage rate, the shrinkage rate of the second-layer ceramic piece is matched, and the bionic human bone with the porosity and the bending strength changing in a gradient mode can be manufactured; cracks and bending of a connection interface caused by mismatching of shrinkage rates of the compact bone and the cancellous bone can be effectively avoided; according to the present invention, by using the different particle sizes of the single powder and adopting the mode of compounding the A-type silicon nitride and the B-type silicon nitride, the sample shrinkage rate and the bending strength after sintering can be adjusted, and when the ratio of the A-type silicon nitride to the B-type silicon nitride is a certain value, the bending strength of the sintered sample achieves the peak value;.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com